If you shoot a custom rifle, you will almost certainly need to trim your cases on a regular basis. Why do I specify ‘custom’ rifle? Don’t all cases need trimming eventually? Maybe.

Generally, if you have a custom barrel on your rifle, the chamber will be a pretty close match to your cartridge case. In other words, if your case ‘grows’ in length, it could end up being longer than the chamber. Not good.

If you allow this to happen – by not trimming your brass – then, when you close the bolt on a live round, the case-mouth will be crimped into the bullet – raising pressure. Dangerous? Could be but that extra pressure will certainly show up on the target and if you are a serious competition shooter you know what that will do to your groups and scores!

Have a look at the picture above. I’ve sectioned a factory 308 barrel and as you can see, the case could grow by about 50 thou. before it needed trimming. With factory chambers, the firearm manufacturers have long realised that many shooters will never trim a case – and keep using the cases ad infinitum – until they split or what have you. So, the chamber on a factory rifle is often significantly longer in the neck area than a custom chamber – to deal with any case growth. A sensible solution! However, don’t assume this is the case – it makes sense to keep your cases trimmed to the length they were when new and of course – keep all your cases the same length for maximum accuracy.

But, back to our custom chamber. The SAAMI (Sporting Arms & Ammunition Manufacturers Institute) permissible length of a new 308 Win cartridge case is 2.015 to 2.020 inches. Taking Lapua as an example – they usually measure 2.015in. right out of the box.

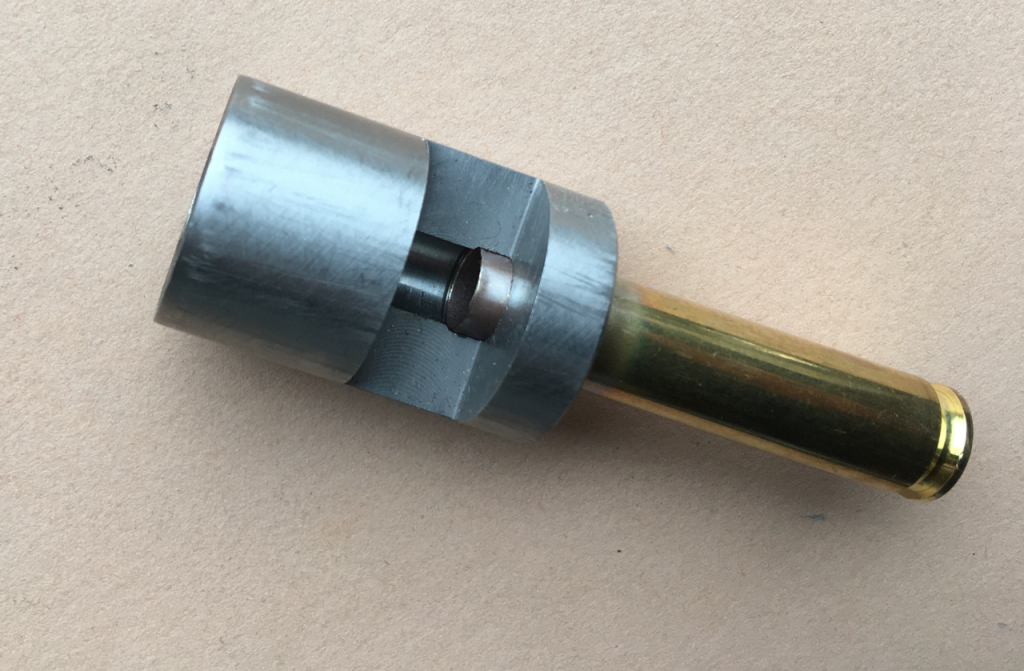

Now, look at the photo above. This is a gauge I’ve made using my 308 match reamer. It’s a small piece of barrel and the milled cut-out is right on the end of the chamber mouth. These gauges are useful for not only checking case-length growth but also accurately measuring case bump and bullet seating depth. You always need to cut an inch or so off the end of a new match barrel-blank and rather than chuck this in the scrap bin, I make these gauges. Ask your gunsmith to do the same next time you have a barrel fitted – he shouldn’t charge too much for half an hour’s work.

My custom 308 Win chamber reamer measures right on SAAMI at 2.020in. – which gives me a permitted case-neck growth of only 5 thou. – you can see the new case is almost touching the end of the chamber neck. I’ve found that with just one firing, I’m close to being in the danger zone, so I always trim my new brass to 2.00 inches dead before firing. This gives me four of five firings before I get near that 2.020 figure. By then, the brass is scrap – or in these days of cost and scarcity of components – ready for annealing and trimming.

I’m running several other custom barrels – 6BR, 6.5-284, 22 Dasher, 6 Creedmore, 6.5 Creedmore, 6.5×47 etc. all in custom chambers so, the case trimming process is a significant part of my reloading routine.

My very first case trimmer was a LEE – I was a novice, nobody told me……. The budget LEE works OK actually and costs little but it doesn’t give you a choice of trim-length and you need to buy a dedicated trim length tool for each cartridge so the LEE doesn’t see much (any) use these days! In fairness to LEE, they’ve upped their game in the trimmer department so worth a look at their latest offerings if you’re not too anal about your case-prep.

My next trimmer was an RCBS ‘universal’ trimmer. This trimmer will work with almost any case and a range of pilots are supplied to suit most case necks. The problem for me was the stepped ‘chuck’ – designed to hold any cartridge case. It worked but……….

I always seem to buy three of everything so when I saw the Lyman Accutrimmer – which is similar to the RCBS but uses your case shell-holder to hold the case accurately and securely in place – I saw it as a step in the right direction – especially if you buy the carbide cutter. The Lyman is cheap and works well and, as with the RCBS, comes with a range of neck-pilots.

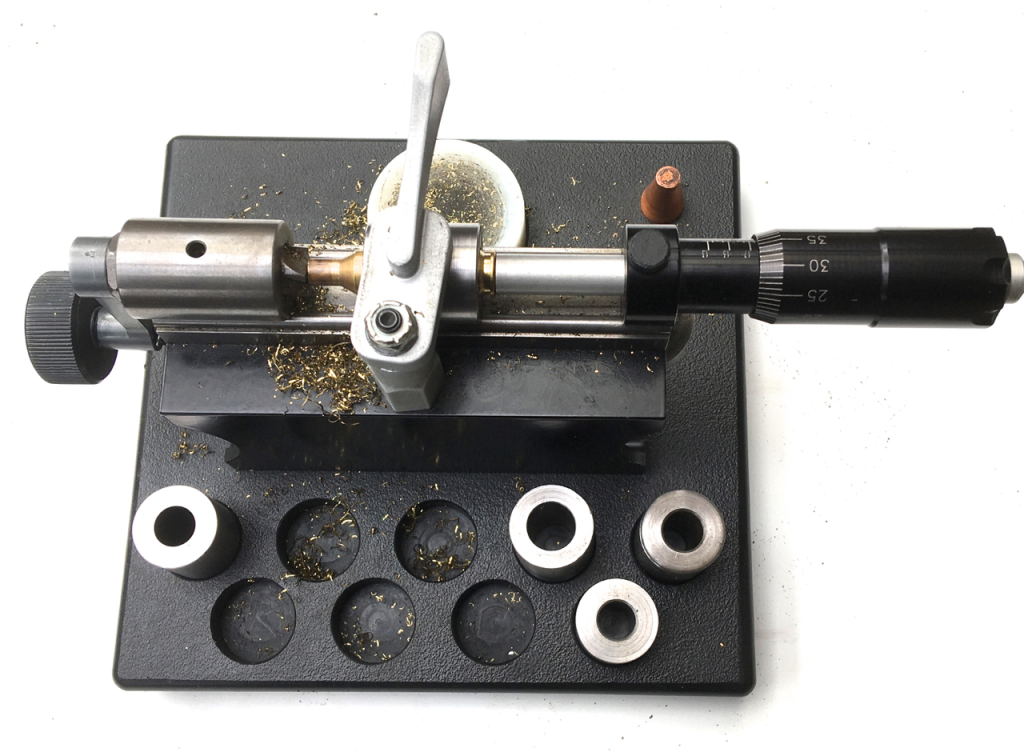

Three? Make that four! When I got into competitive benchrest with a 6PPC I soon noticed that I was a bit lacking in the trimming department – the trimmer to have was the Wilson.

It’s not cheap at around £200 and it needs a dedicated cartridge-case holder for every different cartridge (some will double up) but it’s well worth it. It’s accurate, easy to set up and use and it makes a lovely clean cut. I’m happy.

Like all the aforementioned trimmers, chamfering and de-burring must be done afterwards using the appropriate hand tools. But hey – accuracy doesn’t come from rushing the process. I quickly found out that the slightest case-mouth defect would ruin my 6PPC groups.

There are other trimmers out there. If you shoot a high round-count discipline like PRS – which demands a high level of accuracy – then the acclaimed Gracey powered trimmer will be on your wish list. In addition to trimming to length it also chamfers the neck – inside and out – at the same time. With a claimed output of around 300 cases per hour, this is about 10 times faster than my Wilson! But, at around $400 plus taxes and shipping, I’ll be sticking with the Wilson – for now.

The Giraud is another power trimmer that’s worth a look and if you shoot comps with 100 plus round-counts of the same cartridge, then one of these powered trimmers is surely well worth considering. I’ve never used a powered trimmer but I’ve heard only good things about the Gracey.

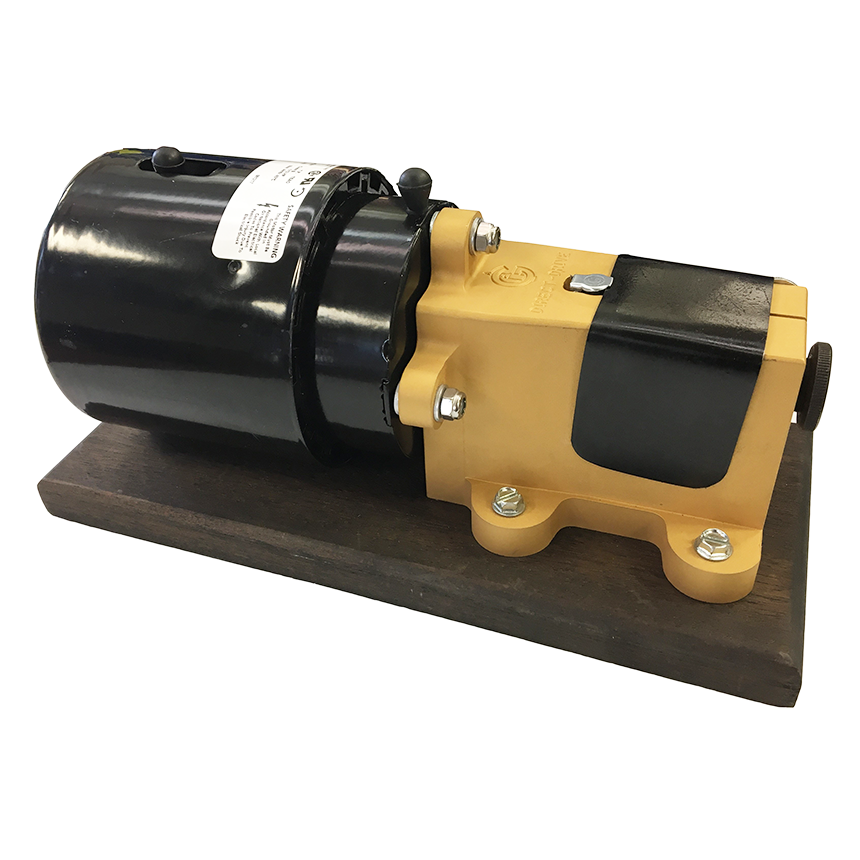

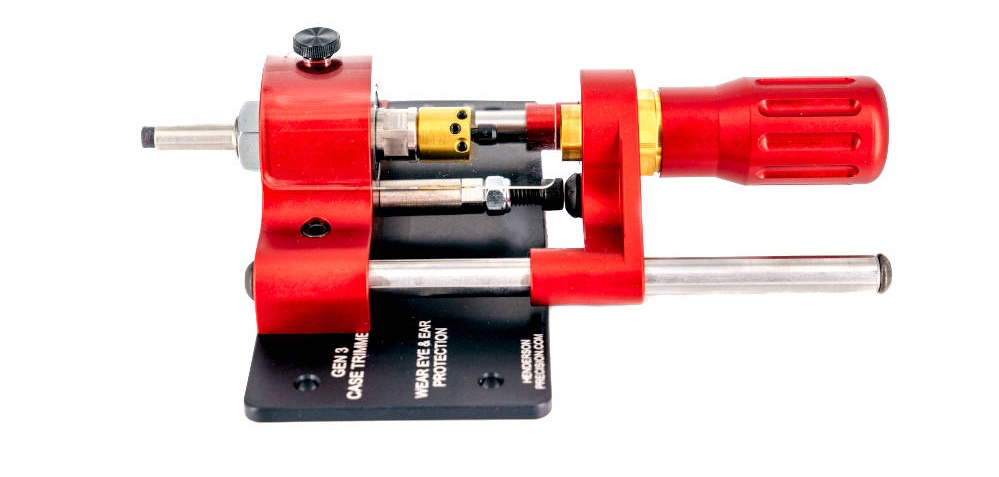

Other manufacturers have now jumped on the ‘motorised bandwaggon’ with RCBS (above) and Hornady – to name but two – are now producing motorised trimmers but these are not in the same league as the Gracey and each stage for the trimming process is carried out separately. Yes, they work but they are unlikely to appeal to the serious competition shooter. The Henderson trimmer (below) however looks very promising but again it’s in the $400 plus price range before duty and shipping

All the aforementioned trimmers are American – can’t we Brits make a quality trimmer? Well, let’s have a look at the ARC trimmer – designed and manufactured the UK by ARC Ballistics and you can add power to increase output.

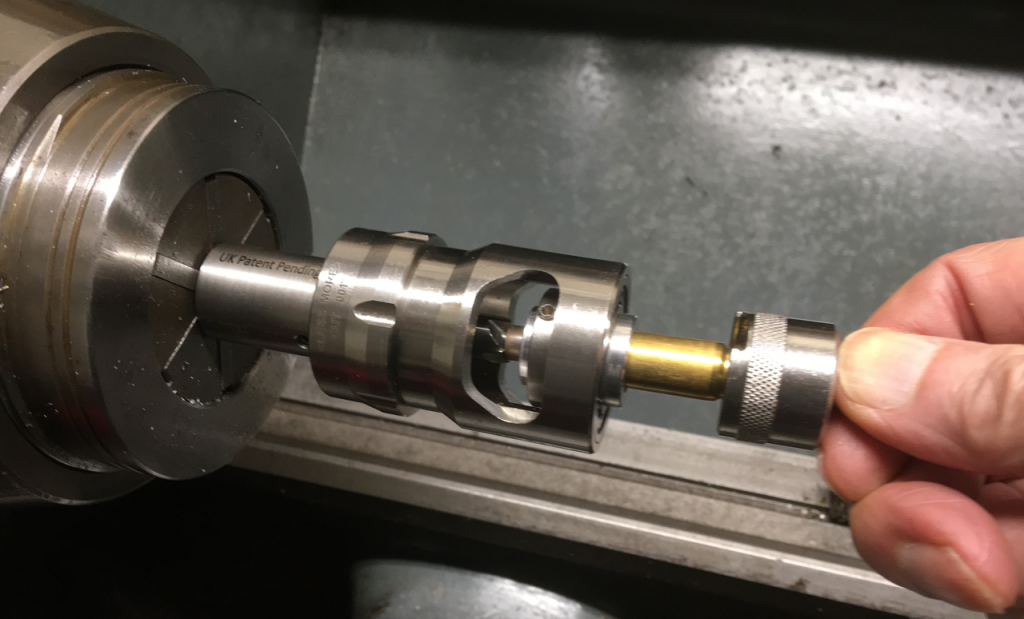

Like the Gracey and Giraud, the ARC trims, chamfers and de-burrs all in one operation. The ARC can be hand-powered like the Wilson or, if you are into trimming larger numbers, you can use an external power source – electric drill, pillar drill or lathe. In other words there is no inbuilt motor – which should at least help to keep the cost down but we are still looking at £474!

This might seem a mind-blowing amount of cash for something you didn’t even know you needed but, if you appreciate fine engineering, you will see the workmanship and design that has gone into this product and remember – it’s British!

As with most of the aforementioned trimmers, the ARC will trim almost any of the popular cartridge necks from 223 to 50BMG and has a super-fine adjustment to the cutting depth. One rotation of the large diameter adjuster body will advance the cutter 25 thou. so it’s not too difficult to apply one thou. adjustments to the cut.

Cases are supported by via a dedicated cartridge bushing system supported on a sealed bearing that indexes on the shoulder of the case and uses TIN coated internal pilots which are a close fit in the case neck and can be supplied to suit your requirement – dependent on your chosen case neck-tension.

You can choose from either ‘standard’ or a ‘match’ pilot size:

Standard size – for use with standard dies using FL die expander balls.

Match size – designed for reloaders using expander mandrels or neck bushing dies – to suit neck tension of .001″-.002″

Although the trimmer can be powered, if you are just trimming a couple of dozen cases it’s no problem to do it by hand, with the case gripped in a holder. When I did a bit of initial trimming to try the ARC, I used the one I use for holding cases whilst neck-turning. Would the motor driven ARC match the Gracey for output and quality? Let’s try it in the lathe.

In practice, we will be trimming maybe 5 to 10 thou. so it’s only a few seconds per case, even by hand. This is similar to my Wilson trimmer but then I need to chamfer inside and outside of the neck whereas the ARC does all three in one go. Using the lathe I put 10 cases through in about 5 minutes – about 30 seconds per case but it takes only a few seconds to cut – the rest of the time is taken in mounting and removing the case from the holder. So, on advice from an ARC user (thank you James) I tried it just holding the case in my fingers – it works and that speeds up the job tremendously. To be honest, if I was just trimming a couple of dozen for benchrest, I’d be happy to do it by hand but if I was doing hundreds…………..

As you can see from the photograph below, the cut from the ARC carbide cutter is extremely precise, needing little or no further work before reloading. With the Wilson, I tend to wire-wool my case-mouths after trimming and de-burring to achieve a high polish and maybe I still would for benchrest but for anything else they’re good to go straight off the ARC cutter.

As standard, the trimmer-system comes with three case support bushings to suit 223, 308 or magnum family of cartridges. Then you choose one of the following calibre-specific cutters and pilots to suit 22, 6mm, 6.5, 7mm, 30cal and 338 necks (Additional cutters can of course be purchased and are easily interchanged within the trimmer body by releasing a single socket-head grub screw). You can also use the trimmer for bullet-meplat trimming using a special carbide cutter.

ARC have lots of other tasty tools for the serious reloader – including dies, expander mandrels, meplat trimmers, primer-pocket uniformers etc. Target Shooter supporters March Scopes carry a good stock of ARC Ballistics – check out the website at http://www.marchscopes.co.uk/arc-ballistics-reloading-tools

Finally, when I first heard about the ARC trimmer I didn’t know anyone using one but then none other than my benchrest shooting buddy Darrell Evans revealed is an ARC user and offered the loan of his ARC for this review. Darrell has shot competitive benchrest at 100, 600 and 1000 yards for many years and features in the UKBRA record books. When it comes to reloading, Darrell leaves nothing on the table – and it shows on his targets.