If you ask any short-range (100 / 200 yard) benchrest shooter he will give you an emphatic YES. All short-range benchrest shooters neck-turn their brass.

Why? Well, the process dates back to a time when brass cartridge cases were not so well made as today’s brass and benchrest cases were often ‘wildcatted’ from military surplus brass – not to mention the legendary 220 Russian brass which was also poor and required something like three thousandths of an inch to be turned off the neck to get it concentric. Today’s 220 Russian brass is made by Lapua and is excellent and would only need a light skim but most benchrest shooters still run an 8 or 9 thou. neck thickness. Much of today’s brass is of excellent quality – some better than others it’s fair to say and will only require a skim-cut to achieve concentricity. Lapua, Norma, Peterson and Alpha are a few of the makes I’ve used recently and all were very good in neck concentricity.

Ideally, neck-turning should achieve two objectives. It should ensure that the neck is the same thickness all the way round and it should reduce the clearance between the chamber-neck and the neck of the loaded round to a couple of thou. – or less! Clearly however, if we turn brass off the neck it will increase the neck to chamber clearance – exactly the opposite to what we are wanting to achieve.

Why do we want a close-fitting concentric neck? Well, if you need me to tell you you’re probably reading the wrong article!

If you are running a standard ‘factory’ chamber in your 308 FTR gun the neck diameter could be 5 or 6 thou. larger than that of your loaded round. If you neck-turn your brass you will only increase that clearance.

To take full advantage of neck-turning, we therefore need to start off with a ‘tight-neck’ custom chamber – something we can’t obtain without a suitable reamer, a new barrel and a good gunsmith.

Short-range benchresters will maybe run with only a couple of thou. clearance between loaded-round neck and chamber neck. Fine for benchrest which is shot in very controlled conditions – i.e. under cover with the opportunity to clean after every match – that is after about 10 – 12 rounds fired.

If you attempt to run an F Class rifle with this sort of clearance you are asking for trouble. Outdoors, the ingress of detritus in the form of dust, grit, grass, water etc will soon reduce that tiny clearance to nothing – not to mention carbon build-up in the chamber neck if you are firing dozens of rounds without cleaning – if that clearance disappears then – boom! You have been warned!

I know some shooters who very lightly skim their case-necks just to remove the odd thou. to make the neck concentric. Is this worth it? Maybe. Personally, for F Class I don’t think it’s worth the trouble – in my opinion, increasing neck/chamber clearance will outweigh slight brass inconsistency – providing you are using quality brass. It’s not too difficult to check all your brass with a tube mike and reject any that are too inconsistent.

OK – so it’s not worth neck-turning unless we are running a tight-neck chamber right? But, is it worth running a tight-neck chamber anyway for F Class and if so, how tight?

Have a look at the results of the recent 2025 European F Class Championships at Bisley a couple of weeks ago. Over 20 nations took part and not all from Europe – Canada, America, South Africa, Australia etc all sent teams as a ‘reccy’ for next year’s Worlds which will be hosted by the NRA at Bisley in August.

All shooting was at 800/900 & 1000 yards on a target with a 10 inch bull & five-inch V bull. If you shoot F Class at ‘club’ level you may regard your V bulls as lucky shots but take a look at the results. In F Open there were dozens of perfect 75 scores and many with 14 V bulls! That’s 14 out of 15 shots in the five-inch V bull! Even in FTR there were many 75s and I found a couple of scores with 14 V bulls. This not only exhibits exceptional shooting, set-up and wind reading but a rifle/ammunition combination of outstanding accuracy.

I regularly shoot 1000 yard benchrest – we shoot five-shot groups and believe me, a five-inch group is an achievement. But to put 14 shots into a five-inch circle…..? Wow! Is it possible to do that without running a tight-neck? Well, if I were to be building a rifle to shoot in next year’s Worlds with this expectation of accuracy, I would certainly be running a tight-neck chamber!

So, if we want to go tight-neck, where do we start? Well, hopefully your gunsmith will be a help here as he will probably have a tight-neck reamer for your chosen cartridge. If not, then your starting point will be a loaded round – where you have turned two or three-thou. off the case-neck or whatever – to make it concentric. You will then ask your ‘smith to order a reamer with a two or three thou. larger neck. Personally, for an F Class rifle, I wouldn’t go closer than three thou. Carbon build-up in the neck after a day’s shooting (c.60 rounds) without cleaning will soon eat up that tiny clearance.

When I first started shooting F Open with the GBFCA League a couple of decades ago, I was running my 1000 yard 7mmWSM benchgun with two-thou. clearance but, I always cleaned between relays i.e after no more than 25 rounds. You have been warned! This rifle had already claimed me a UKBRA record with a 2.67 inch five-shot 1000 yard group so I knew it was accurate enough.

You can leave the reamer/barrel problem to your gunsmith but the neck-turning is down to you. Is it difficult – not really with the proper gear. Is it easy to mess it up? Yes – without the proper gear – which brings us to the point of this article.

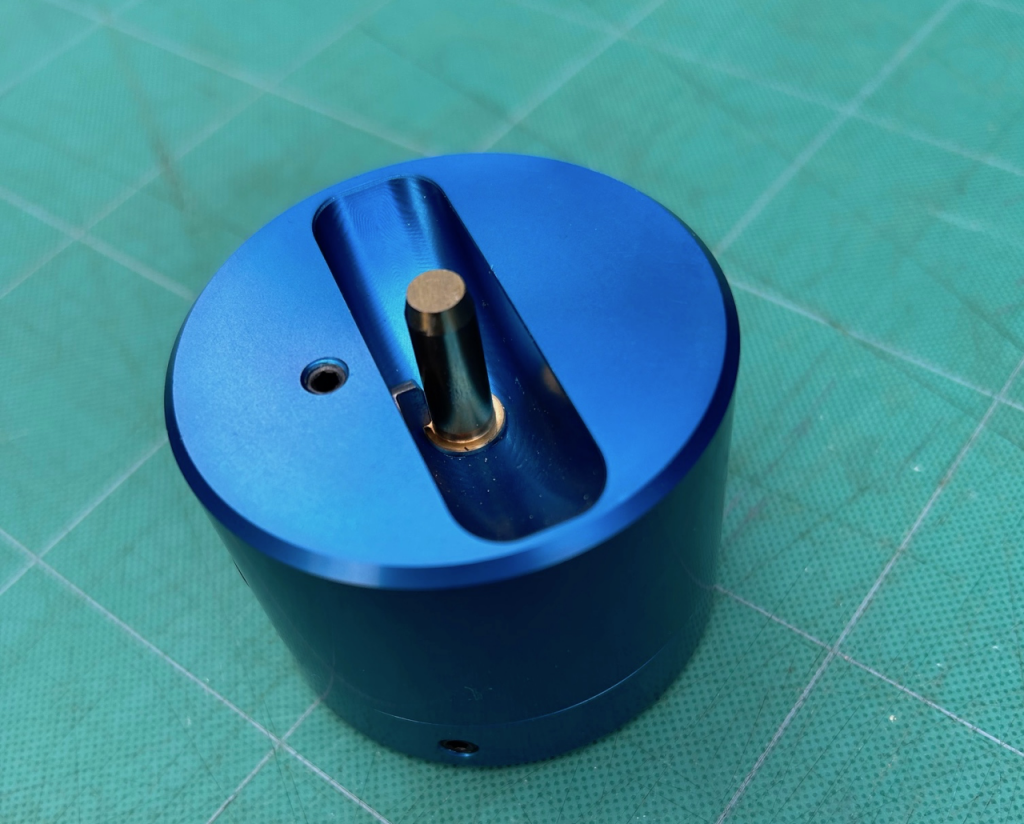

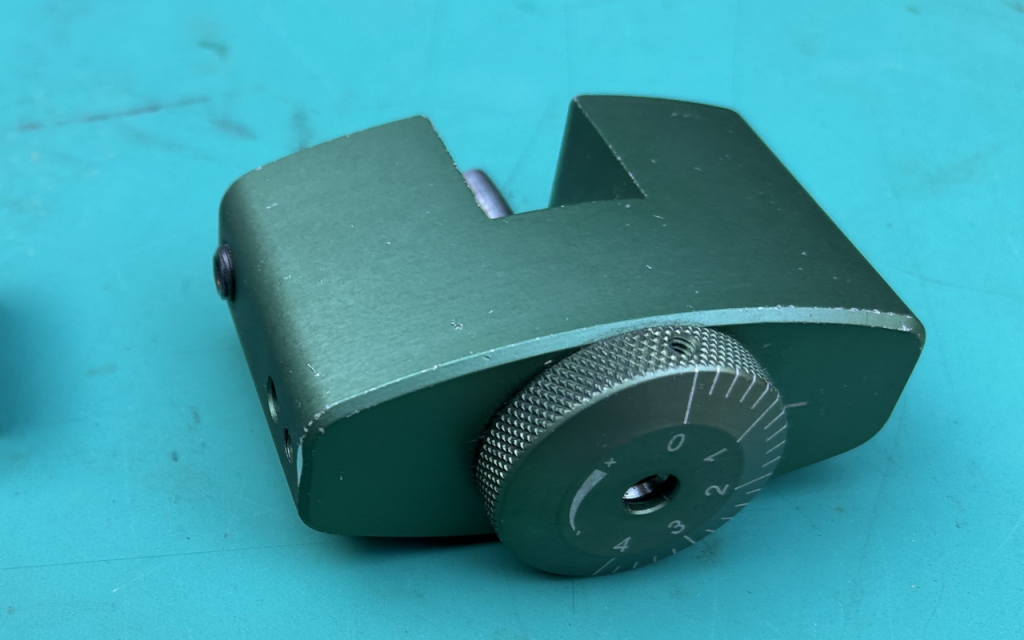

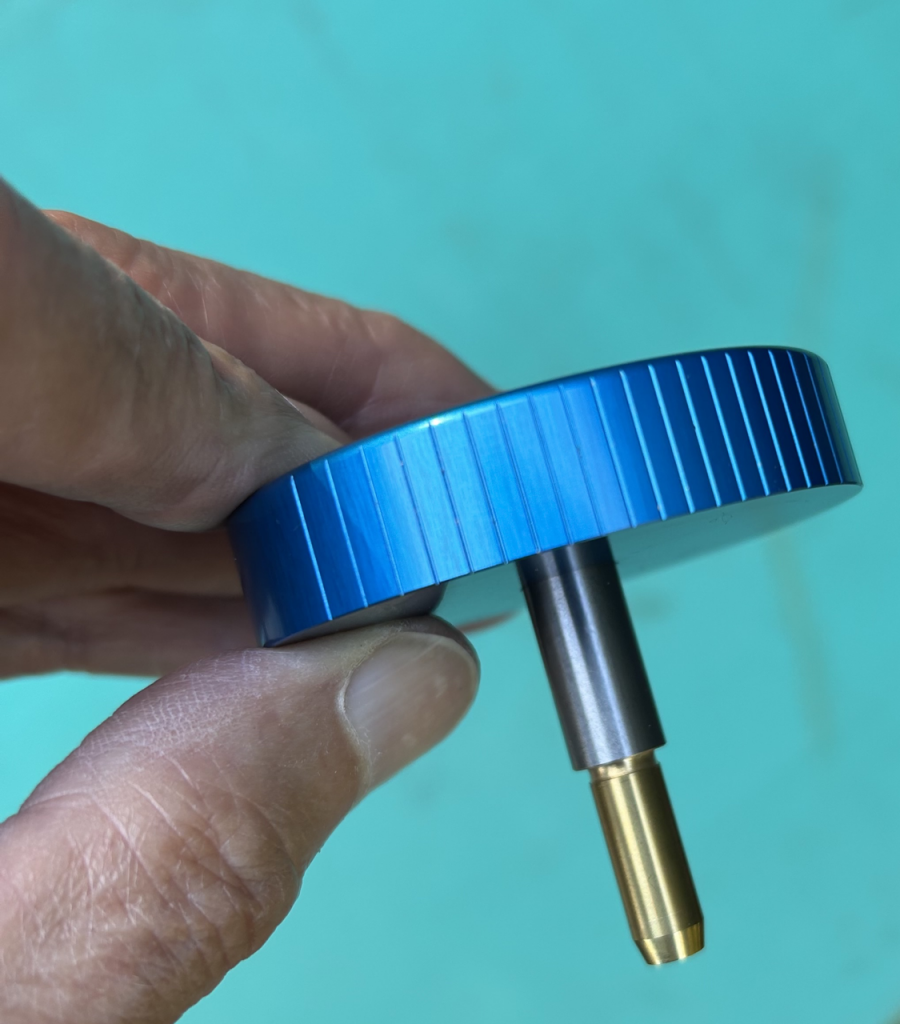

One of the Polish shooters at the Europeans was offering a neck-turning kit which will nicely do the job and we have it for evaluation. It also tells me that the Polish Team were likley neck-turning! The kit contains a digital ‘tube’ micrometer – essential for accurately measuring the case-neck wall thickness, a neck-turning tool and an ‘up-size’ neck mandrel. In addition you will need a bushing neck-die. You could use a full-length body die with a removable bushing but personally, I would size the neck using a Wilson bushing hand-die and arbor press. Use the full-length body die (with the expander-ball removed) for full-length re-sizing and bumping the shoulder – then use the Wilson for the neck.

On my 7mmWSM I was running a 0.312in. chamber neck so I was turning my brass to 13 thou. in the neck area for benchrest. This gives 0.284” (7mm) plus 13 +13 = 0.310 inches. I.e two thou. clearance. Most top F Open shooters are running 7mm cartridges or maybe 30 cal. Do your own calculation but I wouldn’t go closer than three thou. In other words – a loaded round for my 0.312 chamber neck would ideally measure 0.309 inches across the neck.

Also, you may have asked your gunsmith for a 0.312in neck but have you got one? You need to check. Reamers wear down and you could have a marginally tighter neck than you hoped for – danger warning! I check mine by running down the end of a bit of brass bar stock with emery paper – until it just push-fits the chamber-neck – that is your neck diameter no matter what your gunsmith tells you! Turn your brass to give you at least three thou. clearance. Don’t get clever and reduce this – in fact, even in short-range benchrest, shooters are moving away from ultra-tight necks.

For a really good finish on the case-neck, turn it in two steps – with the second step taking a very light cut – say one thou. You can then remove any small ‘tooling’ marks by spinning the case in a power tool with some fine wire wool. Lightly chamfer inside and out as with normal case prep. Do a final check by seating a bullet and measuring the neck diameter. Even bullet diameters can vary so, if you change brands, re-check.

To make these fine cut adjustments on some neck-turning tools is not easy and involves a bit of hit ‘n’ miss to adjust the cut by half a thou. You will waste a case or two to get it right but some neck-turners – like our Polish example – make this much easier by running an eccentric spindle mount – which permits very tiny, very predictable adjustment. Remember, you are chasing ultimate accuracy – mind your work! Case-necks don’t get thicker with firing – they get thinner, so keep a check with a good quality tube mike and maybe segregate your ‘out of spec’ ones to blow-off shots. Keep a selection of bushings to maintain neck-tension. Also, keep a careful check on case overall length – many custom chambers have very little leeway for case-growth.

The other thing we need to consider is the shoulder-angle of our brass. The 308Win has a 20 degree shoulder and so requires a different cutter to say a 284Win which is 35 degrees.

It’s important to just skim the shoulder/neck junction otherwise you will end up with the ‘dreaded doughnut’ inside your case-neck!

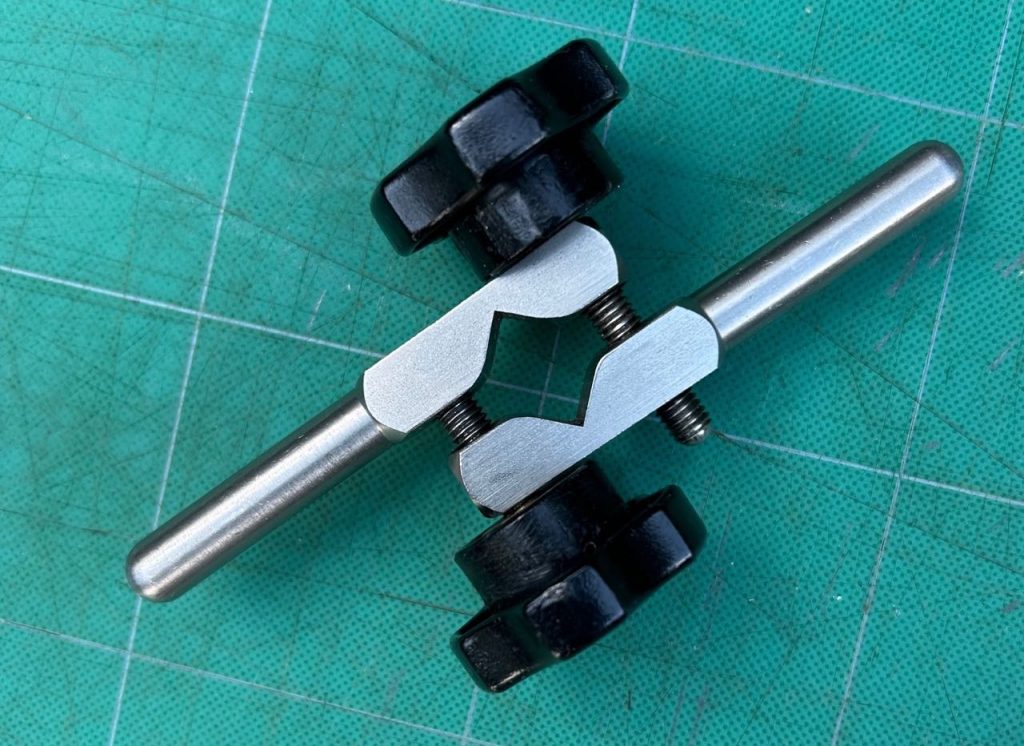

One thing not included with the Polish kit is some means of gripping the case. It takes quite a lot of force to turn brass off a case-neck and I use this clamp (below). You can of course buy a case-holder that you can use with a power tool and yes, once you’ve mastered the process a power tool will speed things up but best to start off by hand using a case-clamp.

The other not so straight forward process is getting your case neck to perfectly fit the neck-turner’s mandrel. It needs to slide on smoothly but without slop – otherwise you are not going to get a perfect cut. Our kit does include a carbide mandrel to exactly upsize the neck so it perfectly fits the neck-turner mandrel.

Before using your neck-turned rounds, always check neck diameter with a good quality micrometer and personally (with the firing-pin removed!) I run all my rounds through the rifle. You don’t want get on the firing-point and find your bolt is a bit tight on closing………..

Finally, do I neck turn for F Class? No, not anymore but I only shoot at club level now. Lapua (and a few other makes) offer brass which is so consistent I’m happy to shoot it right out of the box. With regular annealing it works quite well.

If you want to give it a go Fox Firearms at Diggle Ranges (irvingfox1234@aol.com ) stock an identical neck-turning tool. Buy upsize mandrels from ARC Ballistics and Mitatoyo do an excellent digital tube micrometer.