I looked at this propellant’s slower burning stablemate, StaBALL 6.5, in Reach-Out 10 and promised a report on ‘Match’ within a month or two. Alas, things conspired against this ambition and it took all of 2024 to get three range sessions in to try the stuff. This was frustrating as I wanted to give the grade a thorough test comparing it to equivalent European Reach-compliant powders, not to mention the banned Hodgdon VarGet, and get a report out quickly.

IMPORTANT NOTICE

These components and charges performed safely in the author’s rifles, but may not do so in others. Sound handloading practices should be always used including reducing charges and working up in small steps to maximum values shown in reloading manuals or manufacturers’ online data tables. The 223 Rem charges in this report are tailored to a non-standard custom chamber and are for illustrative purposes only against H4895 and VarGet results in previous Reach-Out features. They must not be used in standard 223 Rem rifles/chambers. Note too, the references in loads for the 308 Win Paramount about the difference between the SAAMI specification barrel used here vs ‘tighter’ barrels on custom riflesmith built ‘TR’ rifles with their increased pressures, and the effects on charge weights and pressures of case choice/capacity.

So, what is StaBALL Match, and why should it merit detailed scrutiny? The Winchester StaBALL trio (‘HD’ magnum powder plus ‘6.5’ and ‘Match’) are new advanced technology propellants from General Dynamics’ St. Marks Powder Co. plant in Florida made using ball-powder manufacturing processes, although they are flat rounded disks not traditional ball-shapes. The generic ‘StaBALL’ product name comes from the claim that they are the first such powders that are temperature-insensitive. For a description of the type, see the earlier piece on the ‘6.5’ grade (https://www.targetshooter.co.uk/?p=3995). Whilst ‘6.5’ provides an alternative to IMR/Hodgdon 4350, ‘Match’ is quicker. Hodgdon’s burn rate listings put it next to the existing conventional Winchester 748 ball grade flanked by Vihtavuori N140 and VarGet on the ‘faster’ side; N540 and Hodgdon CFE-223 on the ‘slower’.

Any new powder in this burn-rate bracket deserves a close look, but this new ‘StaBALL’ grade saw a great deal of hype on its launch with frequent comparisons to VarGet, even claims that it is the ‘new Reach-compliant VarGet’. Mind you, this was probably from people who’d never seen a tin of ‘Match’ let alone loaded anything with it. Our importer Edgar Brothers does however apparently regard it as a product that justifies a premium price as it has set the RRP at £76 / lb (454g), equivalent to around £167 / kg if you want to compare it against Vihtavuori and Reload Swiss prices. (Actual shop prices are usually far lower though, so check with your retailer if considering the powder.) With the new technologies involved which hint at improved flexibility and more consistent internal ballistics than conventional ball-grades, (hence precision from ammunition loaded with it), I felt I should give it a more thorough work-out than other VarGet/H4895 alternatives examined in Reach-Out parts 5 to 9 which were mostly familiar products with known characteristics.

These characteristics aside, the StaBALL powders meter very consistently in both conventional mechanical measures and my RCBS ChargeMaster electronic dispenser. As with all recent St. Marks developed grades, they incorporate an anti-copper fouling additive, and of course there is the claim that they are insensitive to temperature change. (There is no such animal as a completely temperature-stable nitrocellulose-based propellant, but there are marked behavioural differences between types and grades, and until the StaBALL products, ball-type powders were usually reckoned to be among the worst affected.) Finally, Hodgdon claims significant MV gains will be seen in many applications. (Why quote Hodgdon on a Winchester product? Winchester brand reloading powders are now part of the Hodgdon Powder Co. empire, this company undertaking the testing / loads development, bottling, distribution, and marketing, in other words everything other than manufacture.)

Rinse and Repeat

For the testing process, I initially employed the same format as the other VarGet/H4895 alternatives examined in earlier Reach-Out features – 223 Rem, 77gn SMK seated well out to suit the chamber freebore, recent Lapua ‘Match’ cases, and the mild but tough-cup PMC SR Magnum primer (KVB-5,56) loaded with the same tools and techniques as before, and of course fired in the same rifle. That is off the bench at 100 yards in a very heavy 30-inch barrel Savage based custom F-Class rifle, MVs measured on a Labradar chronograph. The sole change was that I loaded and fired 5-round batches rather than the 4s previously employed. That would be expected to increase group sizes by around 10% or so on an equivalent basis.

As in the previous powder comparisons using the 223, I’ll stress that the rifle has a custom match chamber with over 100 thou’ longer ‘freebore’ than the standard SAAMI chamber allowing considerably heavier charges to be used safely, so those shown on the test card are higher than in Hodgdon’s data for this powder and must not be used in a standard 223 Rem rifle / chamber with 77gn bullets. (Hodgdon’s maximum is 24.0gn for a pressure only barely below the SAAMI MAP.)

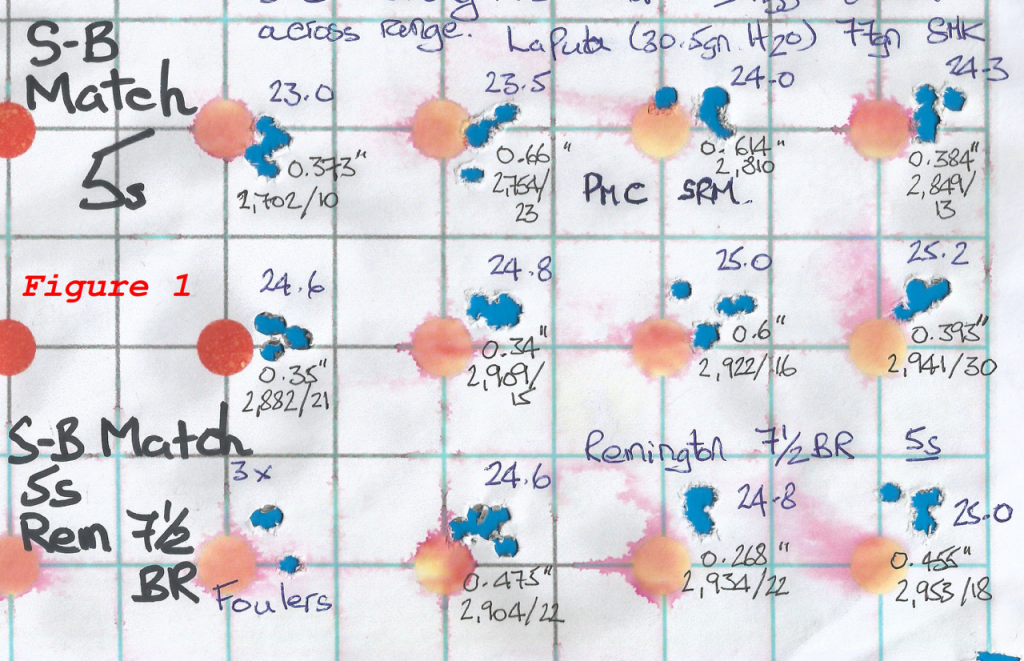

So, we’re off to the range for the first session in early January ’24 with this new powder, eight five-round strings encompassing 23.0 to 25.2gn, plus three of the higher charge batches primed with the considerably ‘hotter’ Remington 7½BR cap. That’s 11 batches / 58-rounds in all (the three additions re-foulers for the primer change). I’d like to say the session enjoyed a mild, still winter’s day with good light, but that wasn’t how things were: cold, very wet, poor visibility, strong crosswinds at the butts end of the range. This is at least partly reflected in the groups with none of the quarter-inchers the rifle is usually capable of with the 77gn Sierra and were obtained with the VarGet and H4895 benchmarks (Reach-Out 6 https://www.targetshooter.co.uk/?p=3811; Reach-Out 8 https://www.targetshooter.co.uk/?p=3934). Nevertheless, five of the eight PMC SRM primed rounds printed under 0.4-inches, and they are 5-round groups this time (Figure 1 top two lines).

24.6 and 24.8gn look promising at a shade over the third-inch. MV spreads were good, the latter seeing several strings in the mid-teens which is excellent for 223. MV increased by an average of ~11 fps per 0.1gn charge weight change, in line with many grades previously tested, maybe a little lower. More important though was the consistency of the change encompassing 60fps across the 0.6gn charge increase over the final four heaviest batches. In other words, rock-steady without MV ‘spikes’ (which point to rapid pressure increases) even with maximum charges. In this barrel and chamber, there were no excessive pressure signs on cases and primers even with the highest charge. As to MVs, the 25.2gn top charge velocity of 2,941 fps was 40-60 fps down on those achieved by the benchmark H4895 and VarGet powders, so no increases. (Hodgdon’s maximum charges of VarGet and ‘Match’ in the 223/77 give the latter a small MV advantage of 2,754 vs 2,737 fps in a 24-inch barrel in its reloading data.

The reason for the final three batches / groups was that many older ball powders perform better with aggressive primers, especially in cold weather. When I tested SR primers some years back, the Rem 7½BR was one of the ‘hotter’ models. So, 24.6, 24.8, and 25.0gn charges were repeated with this cap (Figure 1 bottom line) to see if StaBALL Match also responded in this way. The ignition change produced significant MV increases: 22, 25, and 31 fps respectively, equivalent to 0.2-0.3gn powder charge increases, and no doubt producing higher pressures. 25.0gn StaBALL Match now achieved the 2,950 fps MV I expect from most powders in this rifle with the 77gn SMK. ES values increased by a few fps over the mild PMC-primed equivalents, but were still good by 223 standards and remarkably consistent at 18-22 fps. The average group size over the three charge weights reduced by nearly 10% with the Remington primer – encouraging but maybe not too significant given the small sample size. The lesson here is that primers really matter for both precision and pressure.

All-Change

This cold and wet January range session left me wishing to avoid repeating the experience, and optimist that I am, fondly envisaged a pause of not too many weeks would see us into mild, settled spring days with better light. These fantasies were deflated by wet, windy winter morphing into only slightly less cold, wet, windy spring ……. and summer wasn’t great either! I caught Covid too in late spring, so it wasn’t until the end of August that I resumed testing, now with 308 Win.

Let’s look at the rifle and ammunition components employed. The former was originally a ‘Target Rifle’ (TR) discipline Paramount. Paramount, both as manufacturer and rifle design iteration, dates from 1989 to 1996 and is intermediate between the groundbreaking Swenson-Ingram Swing, and today’s RPA and its products. I had acquired it many years ago at an attractive price, sans sights, and with a well-used but still performing (and very ‘tight’ internally!) Lothar-Walther 14-inch twist barrel as the basis for a stillborn ‘affordable F/TR rifle’ project. Tier-One designed and CNC-machined a superb 20-MOA taper scope rail that fits the receiver like a glove, on which a Nightforce 8-32X56 BR scope was mounted using a Tier-One ‘Monomount’. I say the rifle performed well as purchased, but whilst short-range groups were excellent with 155gn SMKs, the GB NRA’s 308 155gn RWS ammunition suffered a large MV reduction over what it should have been thanks to extensive throat/leade erosion. After some years in this form, the rifle had a brief unsuccessful period re-barrelled to the diminutive .30BR, unsuccessful not because of poor groups, rather the bolt’s disinclination to push the stubby cartridge into the chamber and the contortions required to do so by hand through the loading port.

I had thought my days of handloading and shooting the 308 were over when I stopped shooting F/TR over 10 years ago, but with tools and lots of suitable components retained, plus a couple of 30-calibre barrel blanks on hand, the choice of a replacement cartridge for the BR was a no-brainer. As this would only ever be a short-range tool, a slow (one turn in 13-inches) twist, relatively light (Palma) profile Bartlein 5R rifled barrel was chosen of the pair on hand and had a minimum-SAAMI tight match chamber cut. It was cropped at 28-inches rather than the full 30. Note that this barrel has standard SAAMI bore dimensions, that is 0.300 bore / 0.3080-inch groove diameters. Those who are looking to scope up a custom-built ‘TR’ rifle and handload for it should be aware that riflesmiths specify ‘tighter’ barrels for this genre with internal dimensions around 0.298 / 0.3076-inch which will increase pressures significantly.

Whilst I had half a dozen makes of 308 Win case available, RWS examples from the original NRA procured commercial ammunition and generously donated in once-fired form by a TR shooting friend were used throughout. They are close to Lapua in their weights, neck-thickness, and internal capacities, consistent and strong. Bullets were the only component I lacked, and reverting to my preferences of 30 odd years ago, very tolerant tangent-ogive 155, 168, and 175gn Sierra MatchKings (SMKs) were purchased. I chose the 175gn model for the StaBALL Match test loads, my first use of the bullet in this barrel.

As the reamer was originally specified for the long 155gn Lapua Scenar, the chamber probably has some extra freebore over standard SAAMI, but I’ve ignored that using ‘book loads’ throughout and seating bullets to the COALs indicated in reloading manuals. A Redding ‘body die’ in conjunction with a Lee Collet (neck) die was used for sizing; bullets inserted with a Redding micrometer top ‘Competition’ seater. Hodgdon’s online reloading facility has StaBALL Match data for the 308 Win (alongside a considerable number of other cartridges) and includes the 175gn SMK. It gives a starting load of 42.0gn with a maximum of 46.0gn for 2,677 fps MV and 61,000 psi average pressure in a 24-inch pressure test barrel. That’s with Winchester brass, the pokey Federal 210M (M for Match) primer and the standard SAAMI 2.800-inch COAL.

I loaded seven four-round batches starting at 42gn rising to 45.4gn in RWS cases primed with elderly F210Ms dating from times long past when you could buy these ‘unicorns’ in the UK. I said I was using ‘book loads’, so why stop at 45.4gn not Hodgdon’s 46.0gn? That was because of my lower capacity RWS brass compared to the thin-walled, high-capacity variety used in Hodgdon’s data. Fireformed Winchester cases from my rifle’s chamber hold a full grain weight more water than Lapua and RWS, and some QuickLOAD modelling with equivalent powders, says that charges need to be reduced by 0.6gn to produce same pressures. (Note too that Hodgdon’s top StaBALL Match load produces a high 61,000 psi, only 1,000 short of the SAAMI ceiling, so not much leeway, whereas its VarGet maximum in the same components is 45.0gn for a slightly higher 2,690 fps but generating 48,600 CUP, equivalent to ~56,000 psi.) As with the 223 test rounds three additional batches were loaded with a different primer. As the main lot used the hot F210M, newly acquired mild S&B primers became the alternative. All charges for StaBALL Match and the other three powders loaded to provide comparisons were dispensed on the ChargeMaster, check-weighed on a set of Acculab electronic scales and adjusted as required – very few StaBALL charges needed this, though.

Summertime

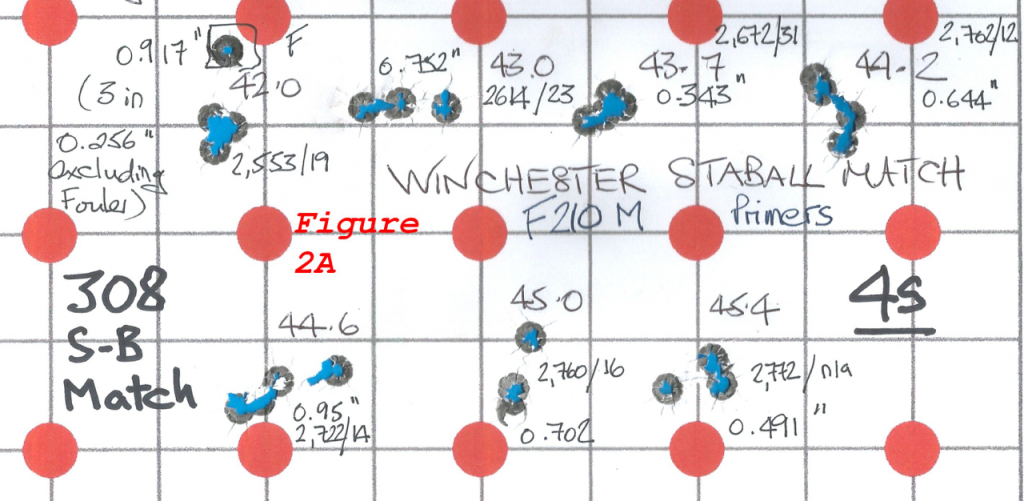

In contrast to the 223 Rem test session, this late August day provided pleasant, ideal testing conditions on Diggle’s excellent benchrest equipped ‘A’ Range: 20-deg C (68F); light breezes, and clear, mirage-free visibility. So, no weather or visibility related excuses if groups were poor. Groups and MVs are shown in Figure 2A.

MVs were good; ES values varied but reduced to 12-16 fps once charges rose a bit; groups were disappointing with four of the seven exceeding half-inch. As this was the first ‘go’ in the rifle with 175gn SMKs, it was possible that the barrel simply didn’t like this model, but the tests with equivalent burn-rate European powders will soon show if this was the case, or not. I’m sure that at least one person reading this is metaphorically raising a hand and protesting that 13-inch twist 308 Win barrels won’t stabilise 175gn bullets. Whilst true for some designs with this weight, the 13-inch pitch allied to the short (1.246-inch max) 175gn SMK produces the optimum Sg (coefficient of stability) value of 1.5 when its length, the 2,722 fps MV associated with the largest group in the series, and other relevant factors from that warm day are input in the Berger bullet stability calculator. There is only one group out of the seven that I regard as good, 43.7gn at just over third inch and 2,672 fps MV. I’ll return to this combination and result toward the end of this report as there are parallels between it and other powders’ performance.

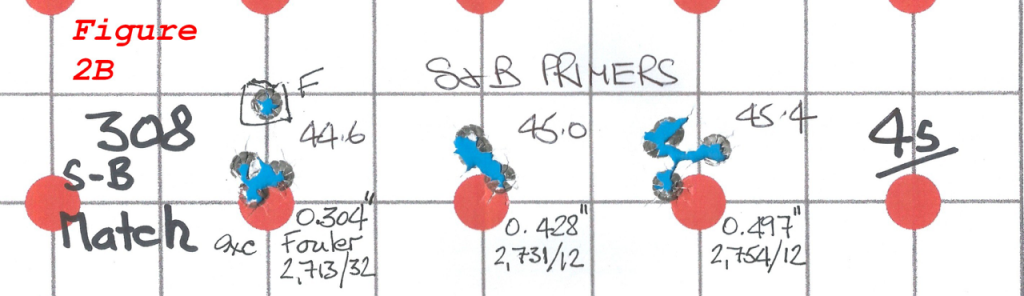

The milder S&B primed batches (Figure 2B) did better with all three groups under the half-inch, albeit the first is reduced to three rounds after excluding the first high fouling shot. With hindsight I wonder why I didn’t load another two or three rounds as ‘foulers’ as I did in 223, and can only assume I was short of sized brass. MV spreads were excellent at 12 fps with these primers, but note the MV reductions from moving to milder ignition – 9, 29, and 18 fps.

Examining both makes of fired primer, that top charge of 45.4gn was clearly close to maximum pressure as the tough-cup F210M produced faint signs of ‘cratering’, and some of the softer-cup S&Bs showed clear extrusion craters around the firing pin indentation. This was the first time I’d experienced the phenomenon with this rifle with either cartridge. I regard this unwelcome innovation as an early warning of excessive pressures, and would reduce that top charge if I continued with the powder.

European Contenders

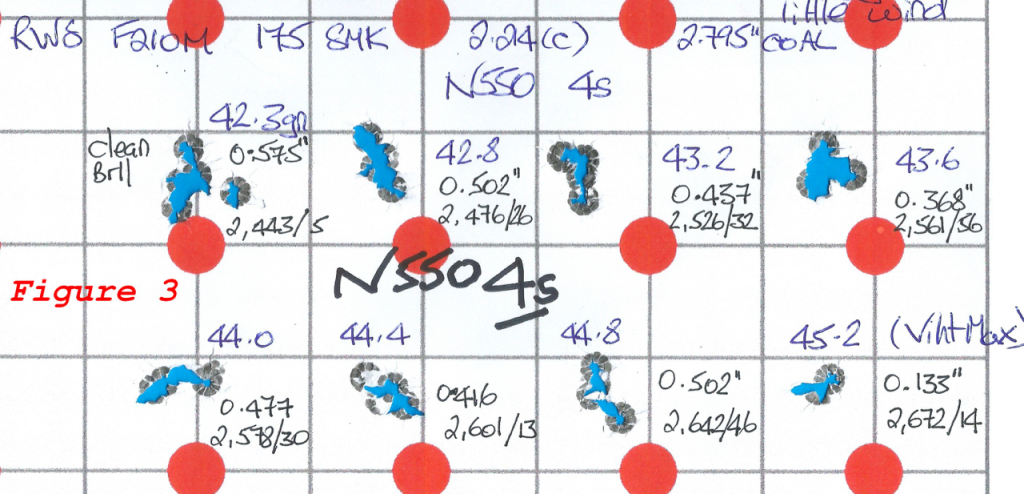

I’ve never fired a cartridge loaded with VarGet in this rifle, and don’t have any left to create a 308 benchmark, so three European manufactured tubular powders were loaded with the same components to provide comparisons – single-based Vihtavuori N150 and Reload Swiss RS50; added nitroglycerin ‘high-energy’ Viht N550. First up, still in this August session, was elderly (2010) N550. Viht’s data include the 175gn SMK, now in Lapua brass, 2.795-inch COAL, and charges from 41.8 to 45.2gn N550, primer not specified, for 2,648 fps in a 24-inch barrel. Eight 4-round batches were loaded from 42.3 to that maximum value. Results are shown in Figure 3, and show an overall improvement compared to the StaBALL groups.

If you allow 2-thou’ leeway on the 42.8gn and 44.8gn groups, everything after the initial ‘fouling’ example was half-inch or smaller, the highest charge seeing a vast reduction to only 0.133-inch. Neither average MVs nor their spreads were impressive, the top load producing 2,672 fps or a full 100 fps down on StaBALL Match. This figure is also only 24 fps higher than Viht’s published figure of 2,648 fps despite four extra inches of barrel on my rifle. ES values ran as high as 56 fps – decidedly poor!

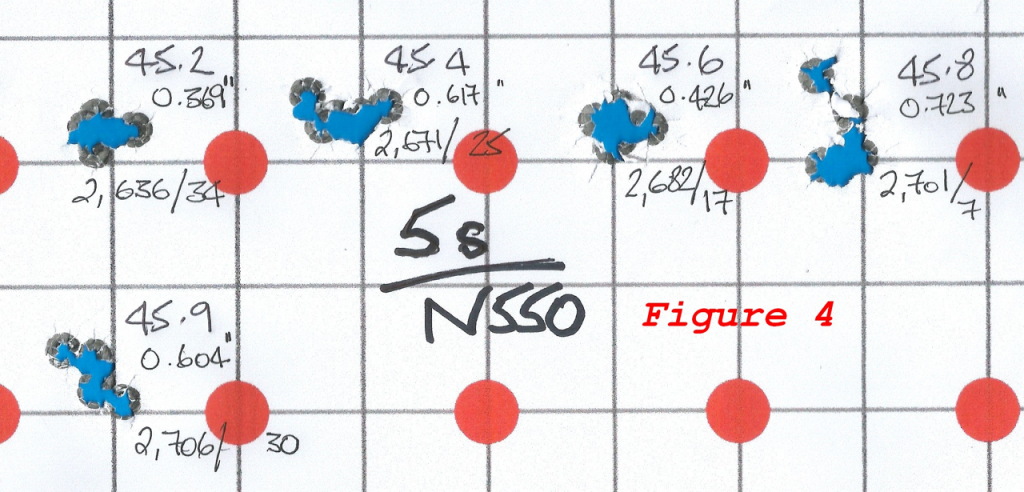

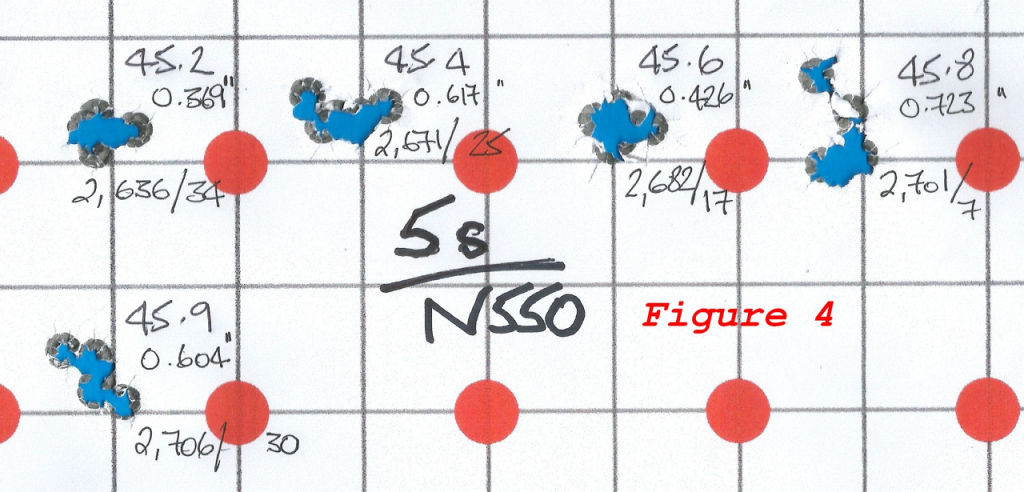

I decided to load further batches, now five rounds each, starting with that 45.2gn charge weight and going up to 45.9gn. Didn’t I say that 45.2gn is Viht’s maximum, so how can I go higher? Whilst Vihtavuori load tables are the obvious first port of call, there are many other reliable sources for 308 Win loads and Viht powders. Lyman’s 51st edition Reloading Manual also includes the 175gn SMK with data for both N150 and 550, the latter with a maximum charge of 46.5gn in a Remington case and the ‘hot’ Rem 9½ primer for 60,200 psi and 2,670 fps MV. Reducing that by 0.6gn again because of the case capacity factor, gave me a new 45.9gn maximum.

Time Travels in my Tardis

Let’s look now at how these five strings did (Figure 4), but both the date and conditions have moved on from the previous card as I’ve boarded my Tardis time-travel ship and jumped to cold, very dark mid-December, only a couple of days short of the winter solstice. Unlike the January session, it was at least dry and windless. Anyway, the 45.2gn charge that did so well back in the summer again performed with the five shots in 0.369-inch, and 45.6gn also proved reasonable at 0.43-inch. The top speed of 2,706 fps from 45.9gn is still 66 fps down on StaBALL Match’s 45.4gn. Mentioning MVs, I was shocked to see the 45.2gn N550 load had ‘lost’ 36 fps compared to its August readings, and wondered what I’d fouled up in my handloading before I remembered temperature change. The second session’s 16 or 17-deg C (29F) colder conditions saw an average MV change of 1.24 fps per degree F which is consistent with expectations for this type of powder. (Note however, that Viht recently upgraded its entire N500 range to make it temperature-stable, so current N550 will be much less affected).

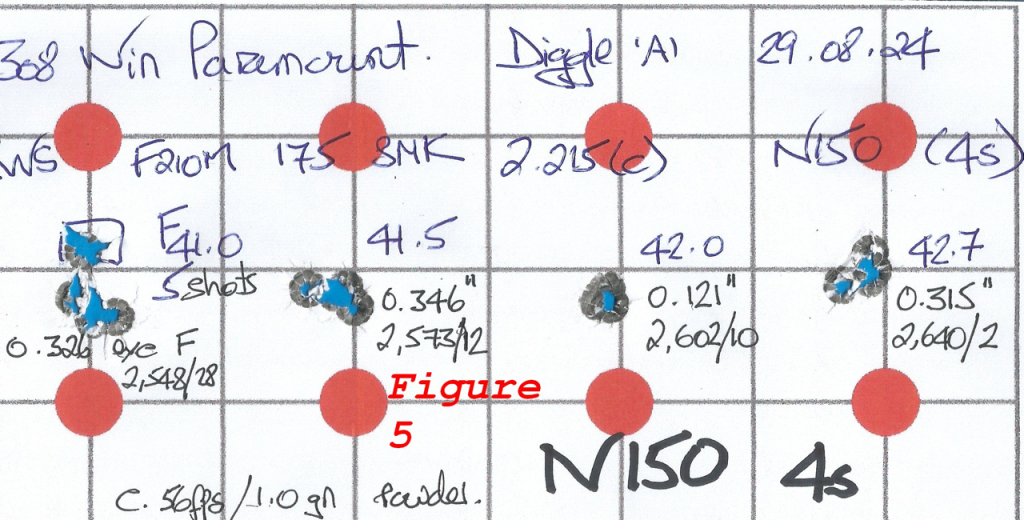

With N550 completed, it’s back to the Tardis to return to that pleasant late August session for Vihtavuori N150, my favourite powder in the 308. Again, it was an elderly batch, February 2010 and bottled within a week of the N550 lot. I’d loaded up seven four-round batches from 41.0 to 44.0gn, the latter above Viht’s very conservative maximum of 42.3gn, again using Lyman’s data which give a top charge of 45.0gn for 59,000 psi and 2,685 fps in the higher capacity Remington case. (Lyman’s maxima for both Hodgdon VarGet and N150 are 45gn and both produce 59,000 psi with the 175gn SMK with an extra 19 fps MV from VarGet, so as many F/TR shooters have noted over the years, the two powders are extremely close in characteristics and performance in the 308. Lyman also obtained a 15 fps higher MV with this bullet from N150 than its high-energy 550 variant.) As with the StaBALL loads, the top three charge weights were replicated with the milder S&B primer. So, 11 batches for 45 rounds in aggregate for this combination, the initial batch having five to provide a fouling shot

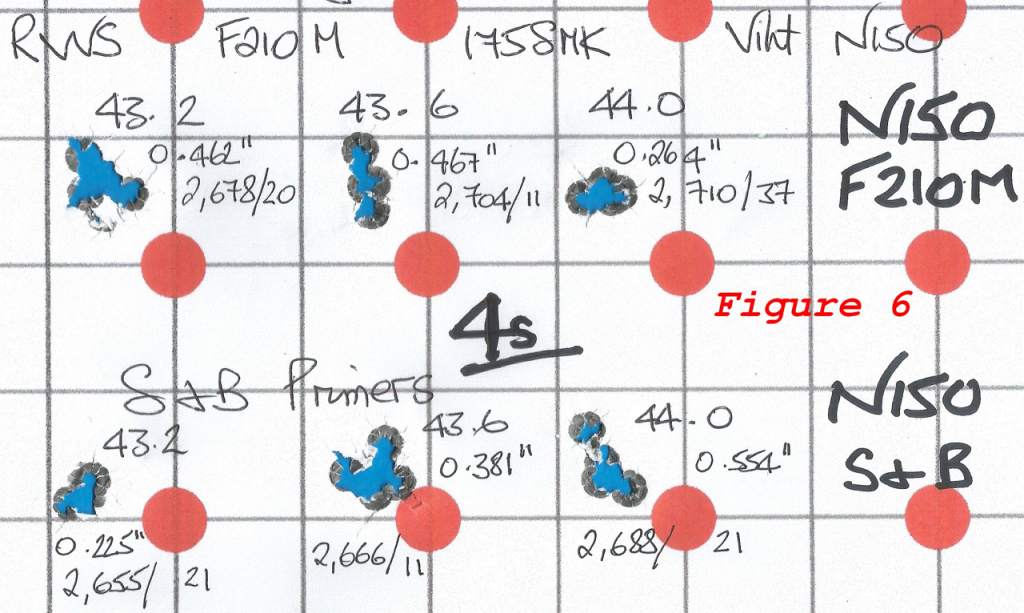

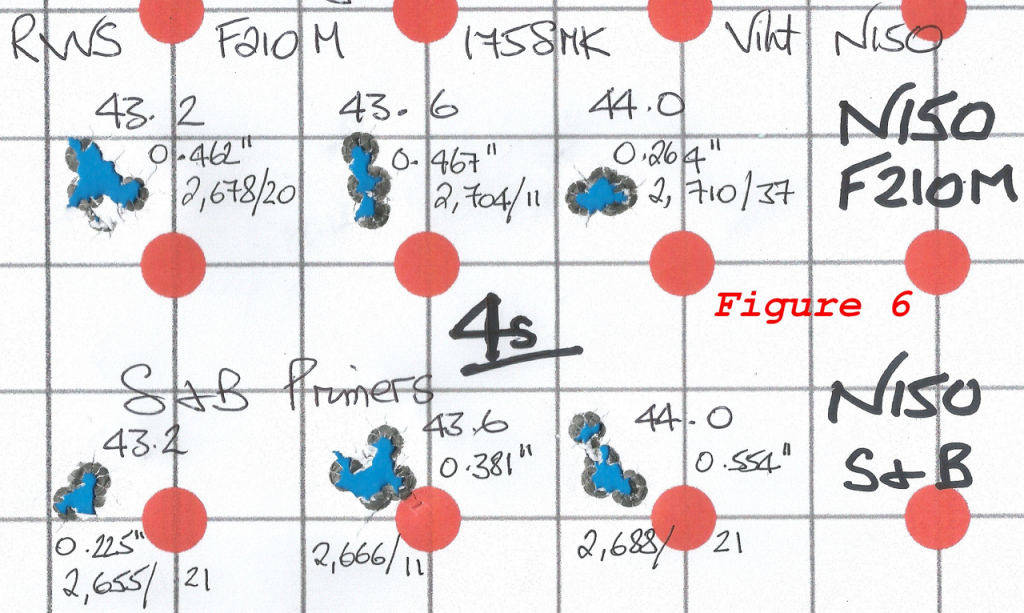

Figure 5 shows the target for the first four N150 / F210M loaded batches, and the groups exhibit a step-change for the better compared to StaBALL Match and N550. With the ‘fouler’ in the first group discounted, the four 4-round batches fired in this session ran from 0.121 to 0.346-inch, and a four-group average of 0.277-inch. After the first group shot from a clean barrel, ES ran at 2 to 12 fps. At this point, the RO called time on shooting, so it’s back to the Tardis and another time-jump to mid-December for the groups from the remaining batches (Figure 6).

Whilst not as good as the lower charges, five out of six were under half-inch and the final F210M primed batch produced a nice shape only just over the quarter-inch for 2,710 fps MV. Unlike the N550 rounds, there was no appreciable MV reduction from the lower temperatures despite this being another 15-year old powder lot. There was nothing between the two powders’ top-charge MVs at 2,710 and 2,706 for N150 and N550 respectively. A result! (to employ a TV sports commentators’ cliche). The substitution of S&B for F210M primers saw one group halved in size, one doubled, and the third moderately reduced, so little overall change. MVs fell by 23, a significant 38, and 22 fps over the equivalent F210M rounds, probably made worse by the low temperature.

Swiss Dessert

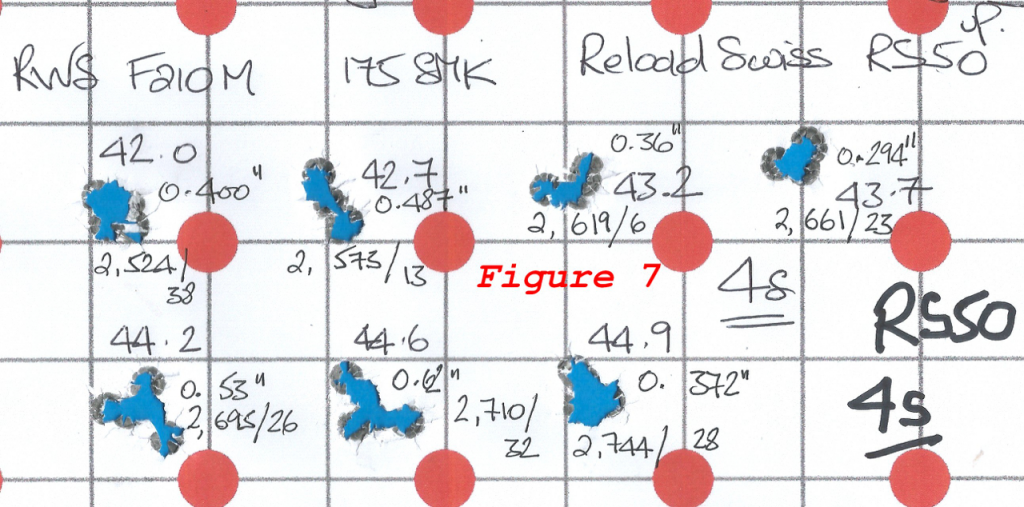

That brings me to my final European powder comparison, Reload Swiss RS50, a high performing single-based tubular type (Figure 7) also shot on that chilly December day. As with N150, seven 4-round lots were loaded, again in F210M primed RWS brass. Charges rose from 42.0 to 44.9gn and saw MVs increase by 220 fps, or 76 fps / grain, much higher than N150’s modest 56 fps. Reload Swiss has comprehensive loads tables on its website, albeit nothing like as much data as Viht now provides, but doesn’t include the 175gn SMK. The nearest equivalent is the 180gn Norma Oryx bonded lead-core hunting bullet whose maximum charge is 44.8gn for 2,507 fps from a 600mm (23.6-inch) barrel and 3681 bar (53,388 psi) pressure. (RWS case and primer in these data.) I worked up to 44.9gn in my tests, and as with both N550 and N150, no pressure signs appeared (unlike the top StaBALL load).

Having successfully used this powder in various 308 rifles over the years loading a range of bullet weights, I expected good precision and high MVs, both of which were duly provided. Again, the top charge’s MV failed to achieve the StaBALL Match equivalent, albeit only 28 fps down, and on a much colder day at that. 43.7gn RS50 produced the smallest group of the seven at 0.294-inch and 2,661 fps. Do that charge weight and MV sound familiar? Go back to the StaBALL Match results and its best group – same charge weight and very similar MV. Coincidence? I doubt it. It also says to me that StaBALL Match and Reload Swiss RS50 exhibit very similar behaviours in the 308 Win, maybe in other applications too. Let’s stretch that ‘coincidence’ even further with 43.6gn N150 and the S&B primer (Figure 6 bottom line): another good group at 2,666 fps and a small MV ES, so tack Viht N150 onto the other pair.

To Summarise ……

I have rather conflicted views over StaBALL Match because of the two very different sets of groups across 223 and 308. Let’s look at the upsides. It does meter superbly in both of my powder measures, that is a traditional volumetric, mechanical type and an electronic dispenser. This is a very important attribute for many handloaders. It does show far less temperament and charge-weight pickiness than older ball grades, and I was impressed by the uniformity of MV increments in line with charge weights and its overall good manners. It did perform well in 223 Rem with relatively heavy bullets despite dire testing conditions.

I’ll take Hodgdon and St. Marks at their word that it is temperature stable and therefore much better than its predecessors. MVs and MV spreads are good, but I’m not so far totally convinced by Hodgdon’s claims for high velocities. (“Velocity levels obtainable, depending on the cartridge, are 50-75fps greater than other propellants in its class.”…………is what Hodgdon says in the product description. See also my MV findings for the ‘6.5’ grade vs H4350 in Reach-Out 10.) StaBALL Match did produce over 60 fps higher MVs than N150/550, and 28 fps more than RS50 in 308, but I feel it was nudging excessive pressures to get there, in my rifle anyway. (Note too, that 0.6gn reduction I made to Hodgdon’s maximum 308 Win charge because of the change of case. Few handloaders even consider this issue, and RWS/Lapua are not the smallest capacity cases that people use, so starting at or close to Hodgdon’s full 46gn could have unpleasant results for some).

My criticism is over those four-round 100-yard groups in 308 Win shot in ideal conditions and temperature. With the exception of a single charge weight’s results, they should have been much smaller in this exceptionally flexible, tolerant cartridge and bullet combination. The switch to the milder S&B primer did help with all three of its groups under the half-inch at the cost of modest MV reductions, so this could be an avenue worth exploring. (Of course, many would rightly retort to this advice in exasperation: “What! Try lots of primers with current shortages and rocketing prices? Pull the other one!”)

I tried to find reviews of the powder, but there is surprisingly little comment on forums and blogs from actual users given that it has been on sale in the USA for a couple of years. What I did find is that those shooters who really like it are overwhelmingly American ‘mouse-gunners’, mostly in 223 Rem, but also loading some of the other new-generation small cartridges developed for the AR-15 and similar platforms. It shoots well for them, is temperature stable, and as they are often high-volume shooters, they love its consistent charges when loaded on progressive presses. My opinion for what it’s worth is that if you are happily using existing ball-type powders in this burn-rate bracket, you’ll probably be even happier with StaBALL Match. If, however, you are a precision before everything else type who tries lots of extruded powders before selecting a ‘killer’ grade and charge, weighs each charge to a small fraction of a grain-weight, and measures groups to two or three decimal places, you likely won’t.

Sellier et Bellot

There was a minor secondary test involved here. I used the ‘hot’ F210M primer in my 308 loads throughout, largely because that is the model used in Hodgdon’s data. It was once regarded by many 308 shooters as the Rolls-Royce of primers in the cartridge and has long been associated with Federal’s much praised factory Gold Medal Match 308 Win loads. However, 210Ms have been as rare as hen’s teeth in the UK for a very long time, and reports from across the pond haven’t been much different in recent years. In these days of primer shortages, my local supplier (Fox Firearms UK) stocks S&B rifle primers in both sizes and it seemed a good opportunity to test a few. I was impressed by the results with both StaBALL and N150, although I wasn’t unduly surprised in that it was the ‘winner’ when I did a Large Rifle primer review in 308 with Viht N140 (https://www.targetshooter.co.uk/?p=1471). Its one downside of 10 years ago, being slightly undersize compared to pockets in other makes of case, has been rectified and these new examples were a snug fit in my RWS cases.

…….. and Finally!

Chris Hodgdon of Hodgdon Powder Company was interviewed at the recent SHOT Show in Las Vegas and finally gave some good news on powder supplies. Deliveries of some Australian manufactured Hodgdon ‘Extreme’ grades that have long been unobtainable are expected this year. Good news for Aussies, Kiwis, and Americans, but not for us thanks to the damnable REACH regulations. Of more direct interest is that Chris Hodgdon denied that the five IMR ‘Enduron’ grades from General Dynamics Canada (which are Reach-compliant), have been discontinued as has been widely reported. The problem is that the manufacturer simply doesn’t have the capacity to make any right now, but will resume production when able to do so. There are no promises about when, but Chris H is confident they will be back sooner or later.

The next two Reach-Out reports will revert to 223 Rem with the 77gn SMK to complete the look at Reach-compliant VarGet/H4895 alternatives and will stay with ball-type powders, albeit older conventional pre-StaBALL products, four from Ramshot; two from Lovex; a sole Hodgdon product.