Let’s face it, not a lot has changed in rifle barrels over the last hundred and odd years. We’ve had barrel manufacturers dabble with cut and button rifling, hammer forging, gain-twist, tapered bores, cryogenic treatment, ratchet rifling, fluting, tuners etc. But, the actual rifled tube has changed little – it’s still just a length of steel bar with a hole down the middle!

However, we have learned many things about barrels – and how to ‘tune’ them to make them ‘shoot’. In other words – harmonics. A short, heavy barrel is not inherently more accurate than a long slender barrel but it is easier to tune – and keep in tune. It’s stiffer and the extra mass handles the heat better.

The most accurate rifles are undoubtedly short-range benchrest rifles – usually chambered for the 6PPC cartridge and employing short, stiff, heavy-profile barrels that will outshoot just about everything out to 300 yards. The word ‘benchrest’ has become a by-word for accuracy and equipment manufacturers shamelessly use the ‘benchrest’ tag to imply that their primers, dies, loading tools etc. are superior in some way.

So now, other disciplines are seeking ‘benchrest’ accuracy and a competitive F Class rifle shares many of the attributes of a benchgun. It’s remarkably easy to tune a 6PPC benchgun – between 28 and 29 grains of Vhitavouri N133 behind a custom 66-68 grain bullet does the job. If it won’t shoot with this combination you may as well chuck your barrel in the scrap bin. The 6PPC barrel will have a competitive life of 1200 to 1500 rounds, so 20 – 30 rounds for load development will not consume too much barrel life.

The F Class rifle or long-range benchgun is another matter. 1000 yard Benchrest competition will burn out a 7mmWSM barrel in 400 rounds! You could easily spend 20% of your barrel’s life just developing a load!

It’s not only F Class and long-range benchrest that is hard on barrels, the relatively new discipline of ELR (extreme long range) can be even worse – simply because shooters are using bigger cartridges. The 338 Lapua Magnum is just the starting point, with cartridges like the 33XC, 37XC, 416 Barrett, 408 Cheytac burning over 100 grains of powder for each pull of the trigger. Barrels must be considered a ‘consumable’ in these disciplines and every round fired in load development is one less in competition.

What if? What if we could have a barrel with zero harmonics? A barrel that would ‘shoot’ over a large spread of different loads. Minimum load-development equals less ‘wasted’ barrel-life. Is that a realistic possiblity? TacomHQ think so.

TacomHQ are dedicated to ELR and you may already be aware of their Charlie TARAC ‘periscope’ device designed to assist ELR shooters who need to exceed the range of normal scope-adjustment when shooting out to extreme ranges – i.e. out to two miles.

So it is TacomHQ who we must credit for making the biggest change to barrel manufacture for well over a century with their ‘structured’ barrel. But what is a structured barrel? I shamelessly borrow a quote from the internet:

“Structured barrels take advantage of axial compression. A physics principle where tubes are always stronger than rods – of equal length and mass. The structure pattern makes each hole act like a tube, resisting tension/compression forces. The opposing forces cancel out, making structured barrels harmonically dead.

Structured barrels are the culmination of many physics principles – harmonics, material acceleration, energy and thermodynamics, working in concert for a harmonically-dead barrel that requires little to no load-development and thus extends barrel-life”.

A structured barrel is claimed to be 56% lighter than a conventional barrel of the same dimensions.

Now, although a fairly experienced benchrest and F Class shooter, I do not feel qualified to even begin to explain the physics behind the TacomHQ structured barrel but, I have seen one, handled one and witnessed its chambering at the hands of Stuart Anselm of GS Precision. https://gs-precision.com

The TacomHQ barrel is – well different! This one is meant for an ELR rifle and is chambered in 33XC. If you’re not familiar with the (ever expanding) range of current ELR cartridges, the 33XC is the invention of David Tubb and has a 338 Lapua Magnum case-head but a good bit longer in the body. You should also know that David is one of America’s most successful long-range rifle shooters, as well as a rifle builder and innovator.

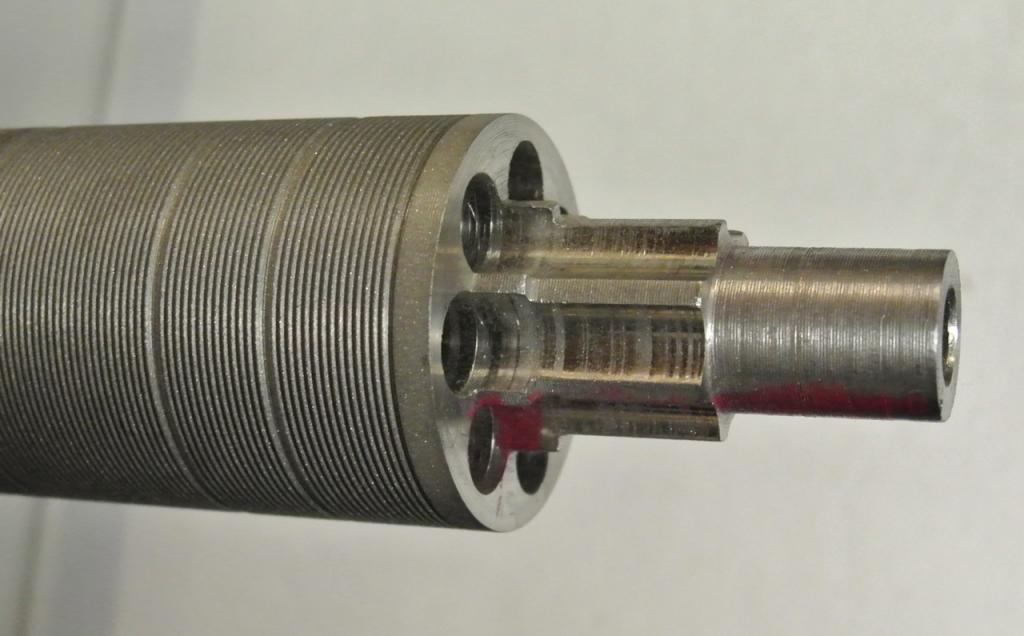

Our blank is 35.25 inches overall (but will finish at 34 inches) and the diameter varies between 1.528 and 1.628 inches. Running these dimensions through one of the many ‘barrel weight calculator’ programmes on the internet reveals that a convention barrel it would weigh around 19 lbs but our structured barrel weighs just 11 pounds – thanks to some extremely clever machining in the form of seven holes drilled along the length of the barrel, radial to the bore! I once had the complexities of deep-hole barrel-drilling explained to me but I cannot begin to imagine how the radial holes were formed.

These holes, together with some other interesting machining, contribute to keeping the weight to that of a conventional barrel of much lighter profile but because of the larger diameter, we end up with a very stiff barrel. The external finish is strange to say the least. It looks like a very rough turning job but it is there to increase the surface area and thus aid cooling.

Thankfully, the barrel machined and chambered very much like any other in Stuart’s hands and it will soon be mated to a Stiller single-shot magnum action and installed in a Cadex chassis. Until we get to witness the rifle on range, there’s not much else I can add but please, have a look at the TacomHQ website – www.tacomhq.com and the informative You Tube videos on the subject.