H4350 Alternatives Part 4 (Conclusion)

Concluding our possible H4350 alternatives, there are three extruded (tubular/stick) products left to have a look at: IMR-4451, Vihtavuori N555, and Norma 204, all of which have nitro-glycerine in their compositions. That order appears to be their approximate burning rate order ranked fast to slow, but that’s a small range and all are close to H4350 so charges aren’t much different. Anyway, let’s take them in that order, therefore starting with IMR-4451.

IMR-4451: the ‘Green 4350’

This is one of five new Reach-compliant ‘Enduron’ grades losing the nasty DNS, DNT whatever modifiers of older IMR products and replacing them with friendly ‘green’ chemicals. (IMR-4166 is the ‘quickest’ somewhere close to H4895; 4451 is very close to H4350; 4955 is in the H4831 bracket. The other two, 7977 and 8133, are slow burning magnum powders.) They are made for Hodgdon by General Dynamics Corporation’s modern plant in Valleyfield, Quebec Province, Canada. Unlike ‘legacy’ IMR grades, all ‘Endurons’ are double-based, but Hodgdon doesn’t quote the nitro-glycerine levels. They incorporate copper fouling deterrents and are claimed to be very temperature stable. Independent tests say that 4451 isn’t quite as good as H4350 in this respect, but I’m pretty sure it’s more than good enough for the British climate and our temperature ranges.

Sierra lists its maximum charge as 44.5gn IMR-4451 with its three 160g bullets – I went marginally higher to 44.7gn given my rifle’s longer non-standard chamber. Whilst Sierra’s max loads produce 2,700 fps in its H4350, Re16, Re17/RS60 data, 4451 is cut off one step earlier at 2,600 fps. In Hodgdon’s data for various similar size cartridges, 4451 and H4350 are alternatively given marginally higher maximum charge weights for similar MVs depending on application, so they’re close in this respect. (In fact, Hodgdon’s max loads for the pair with the 162gn Amax in 7mm-08 are 45.0 and 45.1gn with 4451 having the higher value. That’s in relatively light/roomy Remington brass with Rem 9½ primers, so Lapua users would likely need to reduce Hodgdon’s maximum charge).

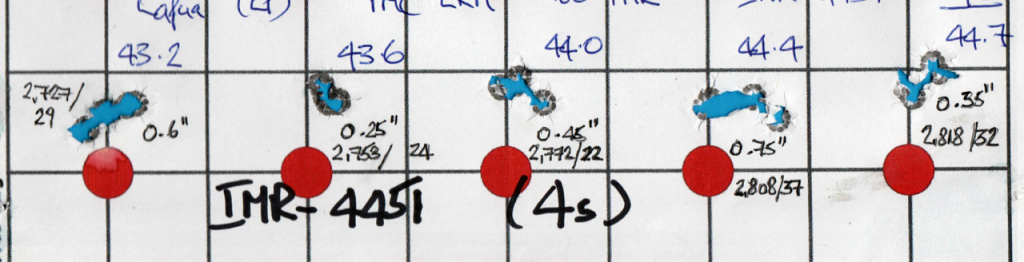

The target scan tells the story: quarter to three-quarter inch 4-shot groups; disappointing ES values of 22-37 fps; slightly higher MVs than from H4350 – c. 44.2gn 4451 equates to the benchmark 45gn H4350. There were no apparent pressure signs with these loads. (I’d tried this powder previously in the 6.5mm Creedmoor with 140gn bullets where it performed well, but not quite as well as either Reload Swiss RS62 or H4350).

N555: Vihtavuori Newcomer

A new Viht powder in this burning rate range is always welcome, especially one designed for the smaller 6.5s and suchlike. I should mention too before I forget that as with all recent-manufacture Viht powder, it has an anti-coppering agent, and that Viht says N555 has been formulated to be very temperature-stable from the off. With N555 introduced in early 2020 and N568 a few months ago, Vihtavuori now has a very comprehensive line-up of slow burning powders, with no fewer than eight grades encompassed by N555 to N570, five of them N500 ‘High-Energy’ types, and that’s not counting an additional two ultra-slow burners for .50BMG and suchlike. (In burning rate order: N555, N160, N560, N165, N565, N568, N170, N570).

I won’t describe N555 fully, or go through how I estimated a range of loads as I did this in my recent look at four Viht N500 series powders in the 260 Rem. (http://www.targetshooter.co.uk/?p=3483) My findings there were that maximum charges aren’t far adrift from N160’s, maybe reduced a smidgeon, so whilst I’d gone up to 46.0gn N160 in these 7mm-08 tests, I stopped at 45.5gn N555 here.

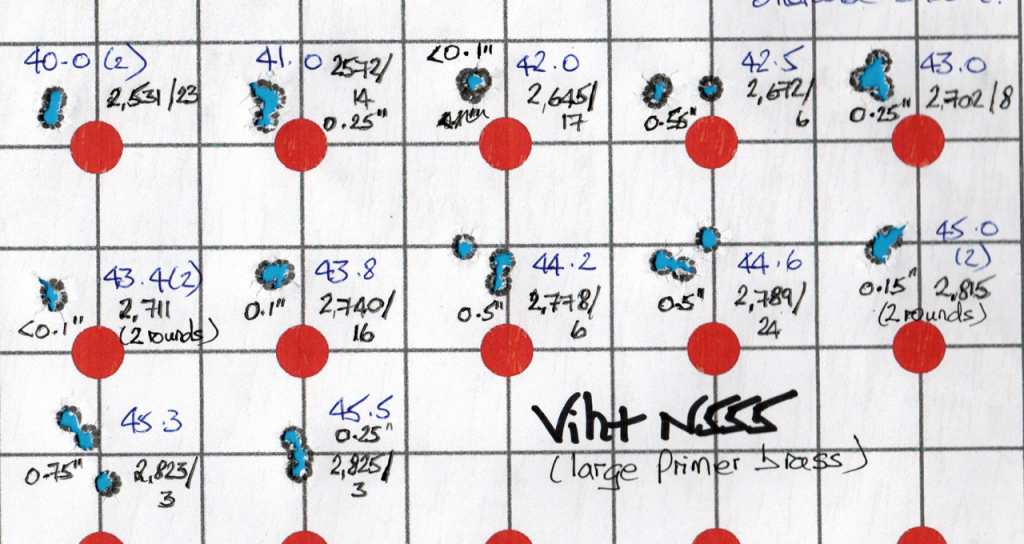

Also, as it’s a still largely unknown quantity with Viht yet to provide 7mm-08 loads, and was missing from my elderly (v.3.6) version of QuickLOAD, I proceeded there from a very low start and used lots of intermediate steps, twelve 3-round batches loaded, fired and chronographed. 44.6gn N555’s MV nearly matched that of 45gn H4350, so they are indeed close. My top load of 45.5gn exceeded both H4350 and Viht N160 MVs at 2,815 fps, a useful premium over the other two of c.40 and 20 fps respectively. No pressure issues appeared, and that’s all I can say on that count. (Incidentally, I’ve recently tried Viht N555 in the 300 Rem SAUM with 200gn bullets and was impressed).

Mean POI gradually climbed alongside charge weights and MVs, but was pretty consistent. Until near top charges were reached, MVs rose by around 65 fps per grain powder, less than I’d expect with some N500 series powders. Groups were promising with lower charges, not so good at the top end whilst ES values were good throughout. There were two odd occurrences. First, two batches – 43.4 and 45.0gn – had one round misfire. When pulled, it was seen the PMC primers hadn’t ignited. I may not have seated them deeply enough – they do like to be pressed in firmly against the bottom of the pocket – or maybe they were simply defective. The other oddity was MVs ‘ran out of steam’ after 45gn, 45.3 rising by 8 fps and 45.5gn by only 2 fps for the final increment. However, both of these charges produced tiny 3 fps spreads, this normally indicating very consistent charge ignition and burn – very strange!

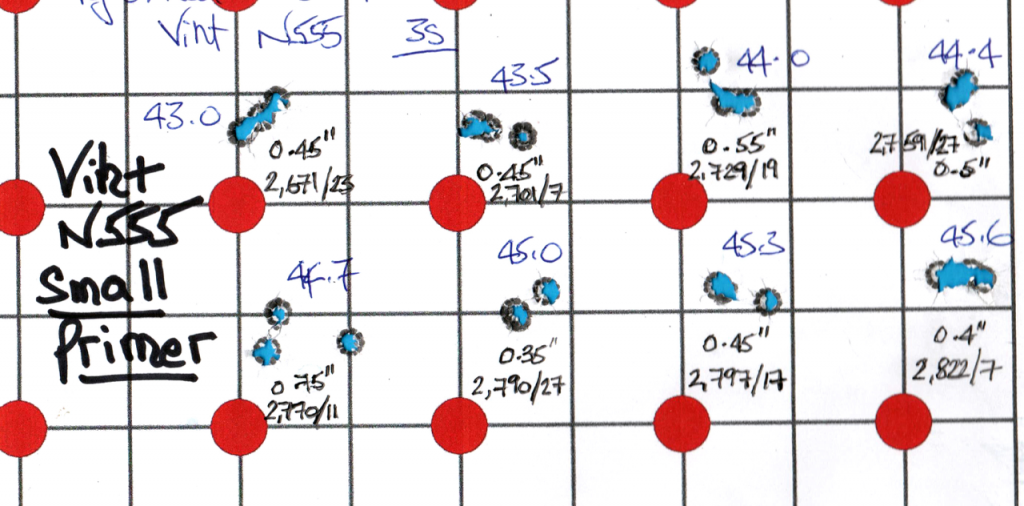

Small Primer Interlude

Having fired my twelve N555 batches to compare against H4350 and the other contenders, I succumbed to an ‘itch’. How would this new powder perform in my reformed 308 Win small primer ‘Palma’ brass? I had a box of same ready sized and primed, so another eight batches were loaded up with N555 and the 160 TMK. Primers were my usual match 7-08 cap in these cases, Rem 7½BRs. If the powder showed promise in out of the box standard brass fired by elderly PMC primers, then it had to do even better in small primer, small flash-hole, batched, neck-turned etc hulls. Surely? Well, it didn’t! Everything bar MV levels was poorer – groups, POI consistency, and MV spreads. What did change for the better was that MVs continued to rise in line with increased charges after 45gn, so that whilst lower loads gave slightly reduced MVs, the last couple caught up with large primer levels, 45.6gn producing 2,822 fps. Go figure! as our American friends say.

I’m not sure what to make of this. Maybe N555 needs the more vigorous ignition that large primers provide. If so, why was the small variety apparently superior with the two heaviest charges? These results, alongside RS62, SO65 and N160’s excellent performance in LR primed cases, have shaken my faith in the superiority of SR brass in the 7mm-08 with at least some of the powders it burns.

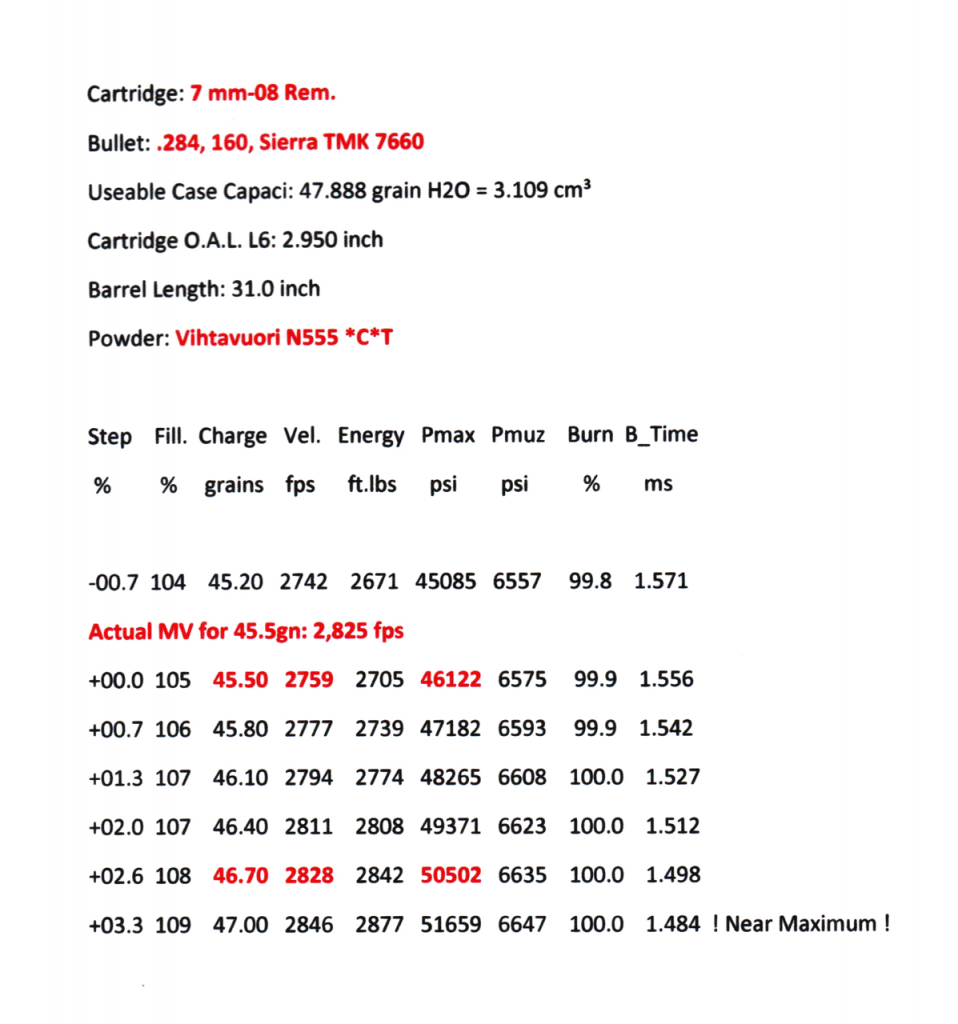

Since I ran this range test, I’ve updated my IT equipment and moved onto the current QuickLOAD v.3.9 which includes this propellant. Running the numbers for this 7mm-08 combination shows QL, as is often the case with Viht powders, underestimates MVs and no doubt pressures, apparently working on Viht data that quantifies the powder’s ‘Ba’ value as slower burning than it actually is. The actual MV for 45.5gn was 66 fps higher than predicted. (Figure 1.) However, even with that result factored in, pressure appears to be remarkably low for the performance achieved, at not much over 50,000 psi if this can be believed. If true, this will make N555 relatively kind to barrels in relation to its performance capability despite its N500 ‘high-energy’ classification.

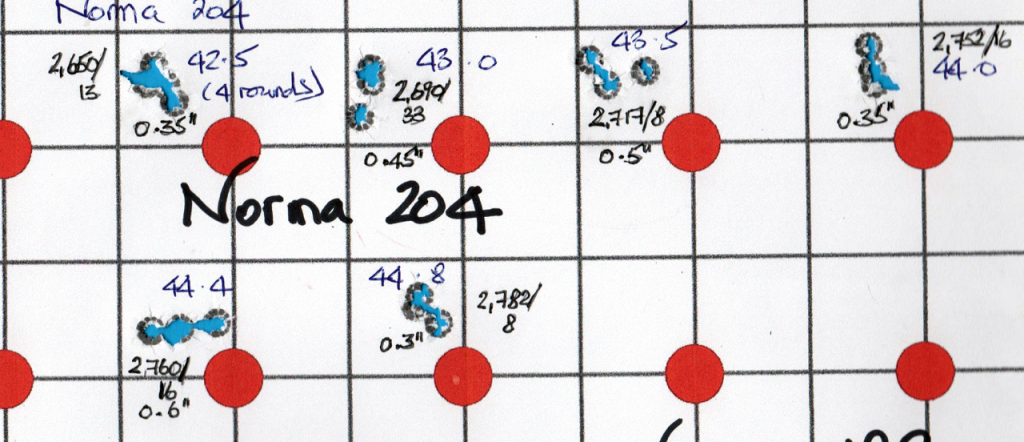

Return of the Swede

Norma 204 is one of these powders that seem to go on forever having been around for many years. It’s double-based as with all Norma powders, but with 4.5% nitro-glycerine content, only mildly so. Looking at the loads data, this grade looked like it might be the closest alternative to H4350 ballistically. I loaded up six batches from 42.5 to 44.8gn, cautiously feeling my way as I’ve not used it before. QuickLOAD v.3.6 calculated that this would only produce 2,724 fps at 49,737 psi Pmax, but in the event, the model underestimated actual MVs, therefore pressures too no doubt, across all charges used. The top load of 44.8gn N204 produced 2,782 fps – same as 45gn H4350 bar a couple of fps – with a nice small 8 fps spread and third-inch group. Returning to QL and fiddling with the figures comes up with an estimated 53,500 psi pressure to achieve this, usefully below H4350 levels.

I’m pretty sure I was over-conservative with this one, and it’ll pay to raise charges a bit, both in terms of MVs and also shrinking groups further. However, 45gn or thereabouts completely fills the little 7-08’s case, even with the rifle’s long-throat chamber and shallower seated bullets. As with some other H4350 alternatives, Norma 204 looks to be a better fit with those larger case cartridges that like 4350-class propellants.

Nevertheless, as the object of this exercise was to ascertain H4350 equivalents, not 7mm-08 performance optimisation, the point remains that Norma 204 and H4350 appear to produce very close performance. There is one aspect though where they’re not alike it seems – temperature stability. Whilst H4350 is famous for its ability to cope with vast temperature ranges, Norma powders (and the pre-TZ Alliant Reloder grades from the same factory) aren’t rated nearly as highly by users. This may be an important consideration for our American readers, rather less so to us permanently chilled Brits.

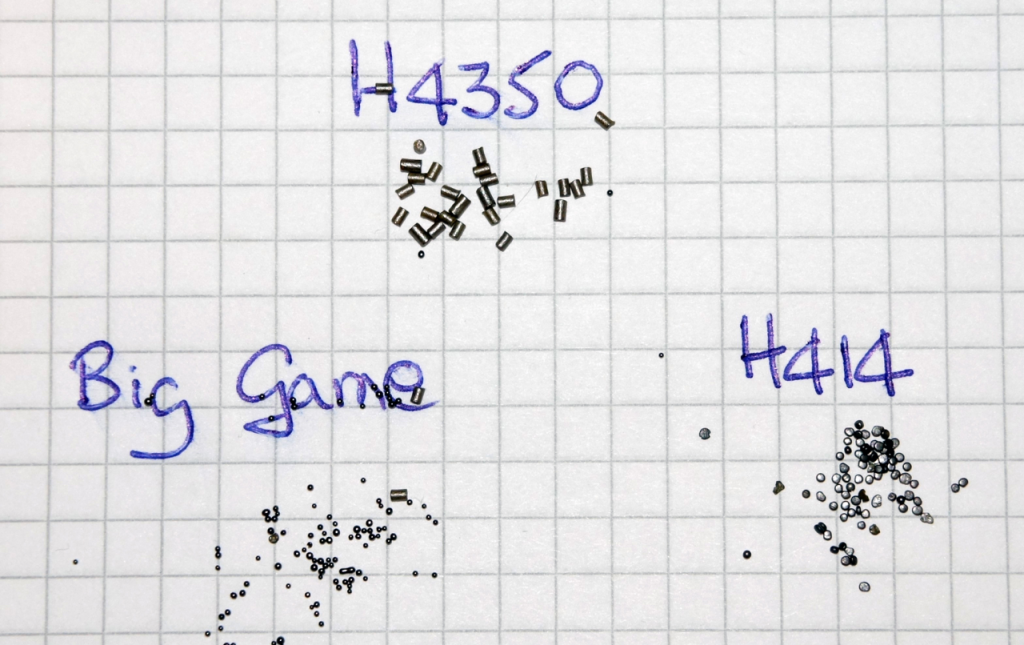

Little Balls; Large Groups

let’s introduce the other benchmark grade, Hodgdon ‘spherical’ H414, and a couple of possible replacements from Ramshot. There are not too many ball-grades available in the 4350-class even in the US, and of the more ‘modern’ products available over there, we have never seen Alliant’s Power-Pro series or the new Winchester StaBALL 6.5 grade, all manufactured by General Dynamics Corporation’s St. Marks plant in Florida. (That odd StaBALL name arises from the merging of ‘stable’ and ‘ball’, it claimed to be the first ever ball-type canister propellant that is impervious to temperature changes.)

Hodgdon (which markets and distributes Winchester brand powders) says StaBALL is particularly suited to 6.5mm Creedmoor, 7mm-08, and 270 Winchester, so it’s a shame we don’t see it here for whatever reason. It has quickly become popular among American shooters who say it does appear to be temperature-stable as claimed, moreover delivers outstanding MVs.

Anyway, with so little choice, the now banned H414 was much appreciated by fans of the type. I rarely use these propellants for precision target disciplines – a touch too fickle in load development, and not always providing consistent performance once you have an apparently good load. However, they’re rightly popular with many field shooters who want to simplify and speed up the reloading process by throwing charges from a volumetric powder measure. Many deerstalkers therefore miss H414. In the US, High-Power XTC competitors often choose the faster burning ball-grades because they perform well in the 223 and are suited to high-volume production on progressive presses.

As with all Hodgdon ‘spherical’ powders, H414 comes from the former Olin Industries plant in St. Marks, Florida, now part of the General Dynamics Corporation. This grade has been around a long time, introduced in 1967, and as with all such older St. Marks products has been steadily improved over the years, becoming easier to ignite and cleaner burning. It’s also packaged and sold as Winchester 760. As with all members of the genre, H414/W760 is double-based, reputedly with a nitro-glycerine content of around 10% by weight, but Olin maintained that its ball powders burn at lower flame temperatures than equivalent single-based extruded types and are therefore actually kinder to barrels.

Ramshot

I could only identify two ball-type products that might potentially stand in for H414 – Ramshot Big Game and Hunter. Although an American marque, part of Western Powders’ stable, most Ramshot branded products originate in Eurenco’s P B Clermont plant in Belgium. This former state powder factory switched to ball types after WW2, buying technology know-how and manufacturing rights from Olin. It is an R&D leader in the type, and sells its products worldwide, most ending up in commercial ‘hunting’ ammunition or military cartridges. Henry Krank is the UK distributor and has built up a body of satisfied users and healthy sales. Both grades are excellent propellants, flow through conventional measures freely and consistently, and burn very cleanly. There is one potential problem though – I’m not convinced either is a close match to H414. Big Game looks maybe faster burning; Hunter is definitely slower.

If the St. Marks / Hodgdon / Winchester ball grades use small kernels compared to stick powders, then Ramshot’s are smaller still. Spill any on the bench and they quickly disperse every which way – fine in conventional measures as they really do flow well and meter consistently through them. Unfortunately, they flow just too easily through the RCBS ChargeMaster electronic dispenser for my liking. Breathe a touch hard over the loading bench and a shower of tiny globes tumble out of the feed-tube and get everywhere – including inside the scales casing where they can cause real problems. So, my old Hornady ‘L-N-L Bench Rest Grade Measure’ is brought back into use with individual charges adjusted up to desired levels using a trickler and scales. If I’m loading enough cartridges in the session, I’ll set up my even older but accurized Ohaus 5-10 beam scales with a TargetMaster automatic trickler, both courtesy of Allan Edwards, the Target Master inventor and manufacturer. As with the extruded powders, test batches were weighed and held to small variances.

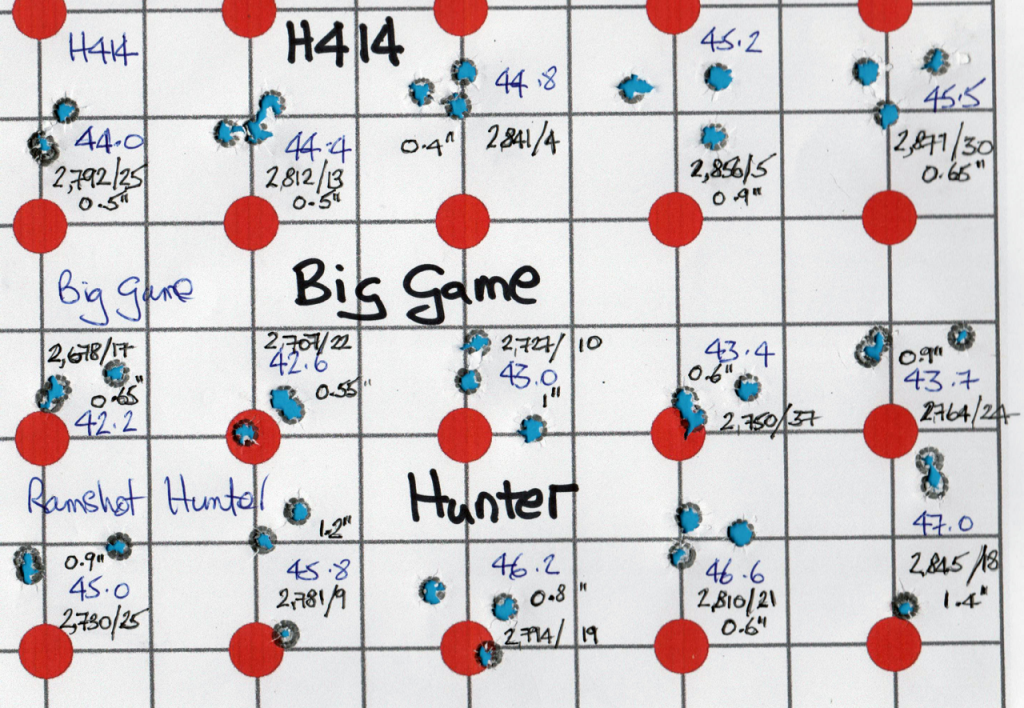

Returning to the benchmark grade, H414, Hodgdon quotes 45.0gn as maximum with the 162gn Hornady Amax, a very similar bullet to my 160gn Sierra TMK. This gives around 10 fps more MV from a 24-inch barrel than the same charge weight of H4350 according to the table. However, it does so at a lower pressure – only 44,500 CUP (Copper Units of Pressure), well below H4350’s 50,500 CUP, not to mention the SAAMI 52,000 CUP pressure ceiling for the 7-08. Hodgdon doesn’t limit H414 loads in other applications, and I’ve found no obvious explanation for this oddity, maybe just a typo. Moreover, QuickLOAD predicted a much healthier 56,000 psi in my long-throat set-up from 45.5gn and that’s what I worked up to.

Ramshot Hunter’s published maximum loads vary depending on source. Sierra’s manual tops out at 48.8gn; Western Powders’ own tables 48.0gn; Nosler Manual No.9 beats everybody else with 49.0gn for its two 160gn bullets. These are for the standard SAAMI short-throat chamber and 2.75-2.8” COALs, too! Such maximum load levels take the powder out of my original definition of ‘possible H4350 alternative’ by exceeding the plus or minus 2gn variance on Hodgdon’s 45.0gn value. QuickLOAD v.3.6 reckoned 47.0gn produced the c.57,000 psi I was seeking in Lapua brass despite the longer chamber. Moreover, it calculated anything much more would be compressed in these cases, and I don’t like this condition with ball powders. Moving onto Big Game, Sierra’s top load is 42.7gn which QL predicted as being barely above 50,000 psi in my long-throat set-up, and it was also a bit down on Western’s pressure barrel-tested data too. In the event I went with 43.7gn in line with the latter source.

On the range, the Labradar said that average MVs for my top charge weights of 45.5 and 47.0gn respectively for H414 and Hunter were 2,871 and 2,845 fps, both close to QL’s calculated values and running at around 56,500 psi. QuickLOAD didn’t do so well with Big Game, actuals running some 50 fps below predictions, the 43.7gn top load producing 2,764 fps compared to an expected 2,817. MV spreads varied across the three grades and their charge weights from a few single figure values up to 37 fps. Taken overall, none produced results in line with the best extruded grades such as RS62 and N160, and within the trio, Big Game produced the largest ES values. (As MVs, and therefore one assumes pressures too, were on the low side this may be the cause – ball powders usually work most efficiently within relatively narrow, high-pressure bands.) Groups from this threesome were also the largest of any powders tried running from half-inch up to Hunter’s 47.0gn 1.4-inch. I’m not sure why I got these results, which weren’t at all expected as I’ve had good results from both Ramshot grades in other applications. It may be that the mild PMC LRM primers weren’t ‘aggressive’ enough for these powders and a truly ‘hot’ magnum cap such as the Federal 215M would have given more consistent performance. In summary, ball-powder fans do have a couple of viable but maybe not optimal Reach-compliant H414 alternatives here. In any event, this pair will be retested as VarGet (Big Game) and H4831 (Hunter) alternatives.

Next Stop … VarGet

This brings the ‘4350 alternatives’ saga to its end. I’ve started range-testing the next two Reach-ban powders, H4895 and VarGet and their alternatives, using 223 Rem with 77g bullets. There are more grades involved in this exercise, an estimated 26 including the two Hodgdon powders, of which seven are ball-types. Rather than wait forever while every possibility is played through before reporting, I’ve divided the ‘players’ up into possible H4895 and VarGet alternatives; then extruded v ‘ball’, and will provide reports covering chunks of four to six powders as I work my way through them.

If the 7mm-08 used for the H4350 group posed challenges and head scratching at times over suitable and safe charge levels, 223 Rem is proving very much worse thanks to its small size / low-capacity case, but also because pressure barrel tested loads in reloading manuals are worked up in the very short freebore SAAMI 223 Rem chamber.

And Now …..

…….. a word from our sponsors. That’s a weak witticism as I pay for most things consumed in these tests, ‘freebies’ only rare occurrences. I do however receive a great deal of help from people in the gun trade in sourcing components, and would like to say ‘Thank you’ to three teams especially. Living in York, I’m very lucky to have two primary handloading suppliers close by – Hannams Reloading Ltd. (Lapua brass and bullets, Berger bullets, Murom primers, Hornady products, Vihtavuori powders, Forster, Lee and Lyman tools plus much more).

Also, Henry Krank over the county border in West Yorkshire (Sierra bullets; Ramshot powders, PPU components and ammunition, Lee tools and much, much else too). Both outfits are great people to deal with who’ve provided excellent service and often gone the extra yard to get things for me.

Of particular note though in these exercises, are the efforts of Fox Firearms UK. Simon Fox has been superb in sourcing supplies of all other powder marques (Norma, Alliant, Lovex and more) and recently introduced grades such as AR-Comp, Re16, Re23, that would have taken me forever and a great deal of trouble and expense to track down and collect in person. The Foxes, father and son, believe in ultra-keen pricing too – always a help in what is becoming an expensive business. I have to say though that it is fortunate I started planning these exercises a couple of years ago and began acquiring components in plenty of time before the current US-originated product shortages and the worldwide shipping supply crisis got under way. I suspect that if I were starting from scratch now, it would be at best difficult, more likely impossible, to source many items.