A Vihtavuori N500 Series Powder Trio in the 260 Remington

Mik Maksimovic’s Dolphin Gun Company put a 28-inch 8-twist Bartlein barrel chambered for 260 Rem onto my FN SPR some time back, but I only managed basic load development with a couple of bullets subsequently. This included Viht N560 paired up with the venerable 142gn Sierra MK but, the combination produced lower than expected MVs, so five follow-up batches had been loaded moving up in 0.3gn steps, ‘fives’ instead of the previous ‘threes’. These 25 rounds then sat in the ammunition cabinet for over a year and two new slow-burning Viht ‘High Energy’ powders – N555 and N565 – bracketing N560’s burn rate had meanwhile become available. So they were acquired and 25 test rounds of each loaded up to try alongside the established grade.

The FN SPR is FNH-USA’s recently discontinued Special Police Rifle, mine originally made in 308 Win during 2005. It utilises the Winchester ‘pre-64’ type (controlled feed) Model 70 action, FN-Herstal having previously bought its manufacturer, the US Repeating Arms Corporation. Add a heavy hammer-forged barrel from an FNH-USA production facility in the American South and various McMillan A-series tactical stocks and you have the SPR – a competitor to the Remington 700 ‘Police’ and suchlike. My A2 version came with the McMillan A4 stock, a design I find ergonomic, comfortable and pleasing to the eye. With its smooth, positive action and magazine feed, this is a rifle I enjoy using, despite its displaying some (many!) perverse tendencies.

Finicky

Given Bartlein cut-rifled stainless match barrel replacing a hammer-forged basically military job, you’d expect a tack-driver, naturally? Er …. not quite! It’s the most finicky piece I load for. It can shoot very well with the right combination but, for every one such there are apparently twenty ‘wrong’ ones – and when a sweet spot is found, the node is usually narrow. I’m not talking three-MOA scatters, as it’ll produce 0.6-1” 100 yard groups regularly enough, often of the four in half-MOA + one flier pattern.

The set-up obviously doesn’t like heavy bullets and/or high pressure loads – this 260 barrel is the rifle’s second such and I ended up shooting nothing but 123gn Lapua Scenars through its predecessor. The M70 action? Maybe, but after much head scratching I suspect it’s a bedding problem, this supported by the number of Snipers Hide Forum threads on pillar bedding these beasts. So, for this exercise, the chronograph is more important than group size – will these powders achieve decent speeds which I’ll define as bettering 2,800 fps with the 142gn Sierra MK? Any good (under 0.5”) low-elevation spread five-round groups are welcome of course!

Components and Powders

The three 25-round lots used either familiar Lapua brass (N560 test lot) or relatively new to the UK Peterson (N555 and N565). All were large primer/2mm dia. flash-hole and fired by Italian Fiocchi LR primers. The Fiocchi is a reasonably consistent performer, bought during the last great components shortage some years back. The Peterson cases are heavier than Lapua’s and have a lower capacity as measured in grains water in fired examples – 53.9 v 54.6gn. (Note thinner Remington 260 brass as used by most American bullet and powder companies in their 260 Rem loading data-sets holds 55.6gn after firing in my rifle. Moving from the Remington to Lapua, even more so Peterson, product will produce higher pressures and maximum charges should be reduced.)

N555/565 lots were ‘fresh’, but the N560 was elderly from February 2010. New supplies may behave slightly differently especially as Vihtavuori has recently reformulated all N500-series grades to be temperature insensitive as well as incorporating an anti-coppering agent across its entire range. The SMKs were also older examples. I mention this because Sierra has changed some of its original MK shapes over recent years. Not only are meplats now ‘pointed’ (ie closed in a die), but nose profiles and bearing surface lengths have sometimes been changed. If this design has been changed, it’s not by much if at all, but COAL / seating depth settings should be rechecked on moving across this production watershed.

When the rifle was rebarrelled it was ‘throated’ longer than SAAMI standard to accommodate 123-142gn match bullets. Seated 20 thou’ off the lands, these SMKs produce 2.93” COAL, or 130 thou’ over standard. This allows slightly higher top charges – QuickLOAD modelling says a full grain difference for 60,000 psi with this bullet and ‘4350-class’ propellants. The shallower bullet seating also allows more powder in the case without excessive charge compression when we get into these slow-burners with 44 to 48gn top charges.

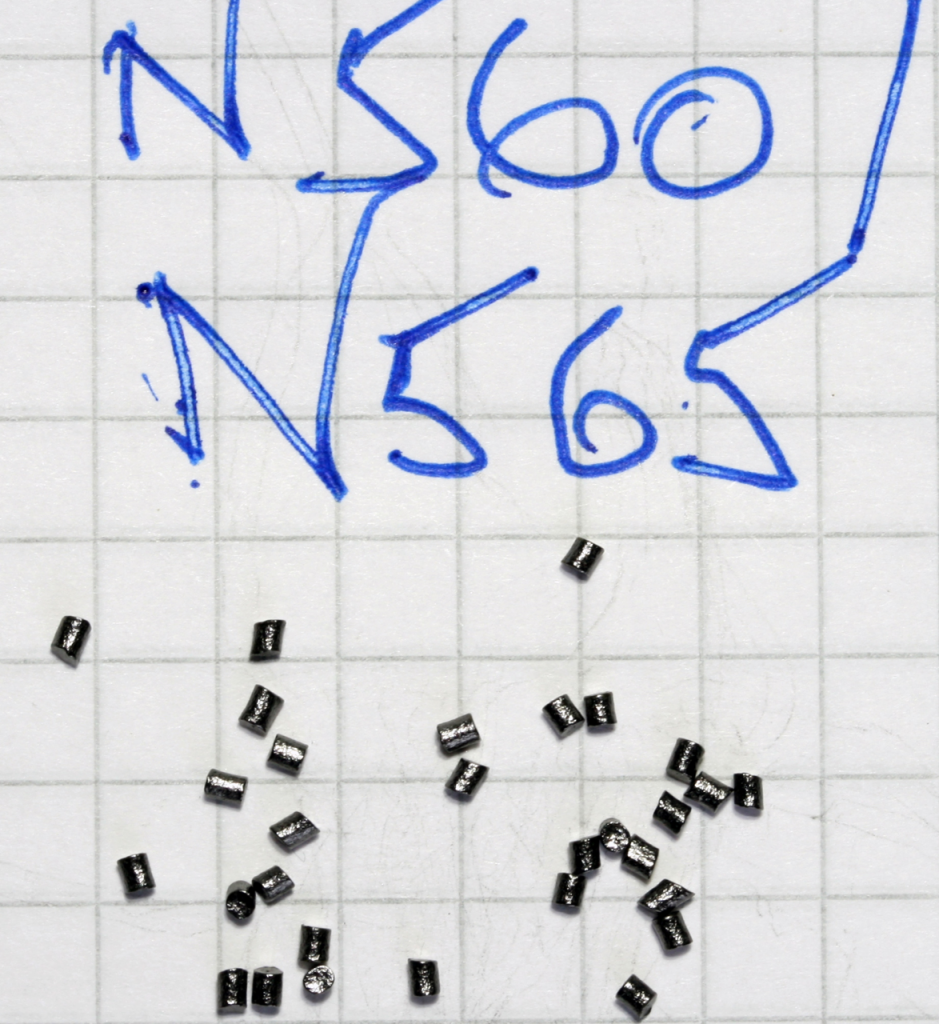

Let’s look at the powders – N555, 560, and 565. Burning rates range from slow to very slow in that order. But before we do that, the pic of the powders as purchased shows three generations of Viht branding and labelling covering a decade, with N555 on the left displaying the latest version now being adopted for the entire range whether N100 or 500 products. Aesthetics aside, compare it to its immediate predecessor in branding terms, the Viht N565 bottle on the right. You can’t miss ‘N555’ on the former whilst ‘N565’ on the latter is printed way down in a tiny font that looks like old-fashioned typewriter lettering and would require some users to hold the bottle up close to the face in order to read it. With so many grades with similar numbers, thank you Vihtavuori for finally highlighting that vital bit of information to avoid mix-ups. As it is, with N550, N555, N560, and N565 in this typescript, I’ve had to repeatedly check that I’ve used the correct designation.

Anyway, the N555 has only been with us a few months and Vihtavuori describes it thus:

VIHTAVUORI N555 – THE ULTIMATE RELOADING POWDER FOR 6.5 CREEDMOOR

Vihtavuori’s new N555 smokeless rifle powder is designed for precision rifle platforms chambered in cartridges such as 6mm Creedmoor, 6.5 Creedmoor, 284 Winchester, 260 Remington and 30-06 Springfield and for rifle calibers with large case volume and comparatively small bullet diameters, among others.

Viht’s frequent mentions that this grade is ideal for the Creedmoors puts it into direct contention with Hodgdon’s (now unavailable) H4350. Falling between existing N550 and N160 grades’ burn speeds, it is much closer to the latter as evidenced by Viht’s maximum charge weights. N555 maxima are usually only fractionally below those for N160 in 6mm and 6.5 Creedmoor, 260 Rem and 6.5x55mm under the same bullets, even a tad higher in several combinations.

I’ve been running a parallel exercise in the gaps between Covid shutdowns looking at alternatives to the ‘Reach’-banned H4350 in my 7mm-08 F-Class rifle and will report on my findings soon. I found that, in that application, N555 is indeed very close to the Hodgdon propellant and showed considerable promise. Many though will worry about it being ‘double-base’ and the likely effect on barrel life. If you fall into this category, take heart for as my shooting friend Richard Huby pithily remarked: “N555? The N100 powder that pretends to be a 500!” Its energy content at 3,700 KJ / Kg is the lowest of the N500 series, and exactly as per N120, 140, and 170. It is a ‘short-cut’ powder with short but quite ‘chunky’ kernels so should meter reasonably. Despite the modest kernel size its specific density is the lowest of the N500 series at 900 grams/litre (960 g/l is the norm) presumably due to lower nitroglycerin levels. 900 g/l puts it very close to N140 and 150 and will give an idea as to case-fills should you use either of those single-based grades in small cartridges like the 6mmBR.

N560 is a long-established product and with its 4,000 KJ/Kg energy rating, aggressive too. Despite Viht saying its N100 and N500 equivalents share burning rates, the usual practical effect is to make the ‘High Energy’ variant act as if ‘slower’ and this certainly applies to the 160/560 duo. Maximum N560 charges are significantly higher but, unlike some other N500s, can produce substantial velocity gains. It sees some use in the 260 and can give good results, likely at lower pressures than from single-based N160.

N565, another 4,000 KJ/Kg ‘hottie’, was introduced a couple of years ago, designed for a specific application – the 338 Lapua Magnum with 250gn bullets. Vihtavuori lists it for other cartridges that benefit from slow-burning powders and, as some 260 Rem data are included for heavy bullets, I bought a tub to give it a try even though I suspect it is only marginally suitable. (It should be well matched to larger case capacity 6.5s such as 6.5X55, 6.5-284 Norma and the new ‘overbore’ 6.5mm PRC; also 284 Win/Shehane/KMR and 7mm SAUM/WSM etc with heavy bullets in match loadings.) It shares its kernel dimensions with those of N560 – slightly longer and noticeably fatter than N555’s – and also N560’s nominal bulk density of 960 grams / litre.

Loading Bench

Cases were full-length resized but not with a conventional die employing an expander ball and de-capper assembly. After de-capping and cleaning cases, their body and shoulder areas were sized with a Redding ‘body die’ followed by a Lee Collet (LCD) type on the neck. Bullets were seated with a Forster ‘BR’ model with its tensioned sliding case-support sleeve. The ‘body die’ plus LCD combination has become popular in recent years as the latter gives very consistent neck tension and copes well with brass thickness variations, also provides good alignment with its floating mandrel. The ‘body die’ was set to ‘bump’ the shoulder back by 0.001” from the fired state. A Forster Co-Ax press held and powered everything.

Every loaded round had its case-head to bullet ogive measured using a Hornady L-N-L comparator and working to ±0.001 tolerance on the set measurement. Quality loading tools, even more crucially the consistency of modern match bullets, only rarely produced a round outside that 0.002” window. No case preparation or batching was done other than mouth chamfering. The 260 case grows quickly with a combination of stiff loads and full-length sizing, so OAL measurement after resizing, then trimming if needed, are essential jobs as a part of the handloading process – trimming is needed every second or third cycle.

Primers were seated with a hand priming tool – not the Co-Ax press facility. Charges were first dispensed on an RCBS ChargeMaster then check-weighed on a set of electronic Acculab scales and adjusted if necessary. Charge weight steps varied across the three powders and differed from my usual testing pattern where I have one, sometimes two, initial larger steps followed by a fixed smaller increment (usually 0.4gn in this cartridge) up to a pre-determined maximum. Where available, a QuickLOAD ‘Charge Variations’ table print was taken to the range and actual MVs checked against calculated values.

I’d mentioned this was a second ‘go’ with N560. The first had topped out at 45.8gn which had produced 2,757 fps, whilst QuickLOAD had computed 2,832 fps – and that at only 50,272 psi PMax! (2,757 fps is equivalent to a mere 46,100 psi chamber pressure in QL’s calculations.) Groups were also disappointing. Viht’s maximum for the nearest equivalent 140gn lead-core bullet is 46.1gn, also in Lapua brass, producing 2,736 fps MV from a 600mm (23.6”) test barrel, so my actual MV was still 75-100 fps low given the rifle’s 28-inch barrel. (This is why a chronograph is so important for long-range shooting, as without accurate MVs you’re guesstimating elevation and windage settings and possibly very inaccurately at that.) N560 testing V2.0 had charges rise in 0.3gn stages to 47.3gn which QuickLOAD now predicted would produce an impressive 2,930 fps at a bit over 56,000 psi, normal working pressures in other words. Too good to be true of course! Equally pertinently here, this weight has a (correctly) QL-predicted fill-ratio of 105% in the Lapua case, moderately compressed, despite the shallower bullet seating with the long chamber throat, so this was the effective maximum – short of moving to heavier case-neck tension with a heavily compressed load.

N555 charge weights needed caution given unfamiliarity with this new grade and Viht’s very limited data for the cartridge. I mentioned that desk research had shown Viht’s maximum N555 loads bracket those for N160 across a range of similar size cartridges and had validated this relationship in my 7mm-08 tests. Although many 260 Rem rifles seem happy with 44.5gn N160 and 140s, I’d found 44.0gn maximum in the finicky FN with the 142gn SMK, so this weight was chosen as the N555 ceiling despite its being lower than those for the nearest equivalent bullets in the Viht data. 41gn was chosen as a starting charge and the first two increments were a full grain followed by 0.5gn steps between 43 and 44gn.

Moving onto N565, I’d settled on 48gn maximum charge for the very slow burning powder based on Viht’s data, again reducing it a bit. My concern now was whether that amount would physically fit into the case even with shallower bullet seating. So step one was to weigh out the charge and pour it very slowly into a sized Peterson case through the 5-inch drop tube Forster funnel, also employing a ‘swirl pour’ to help align the kernels in the case-body. The result just kissed the neck, so it was inevitably going to see some compression with around 0.22” of bullet tail sitting below there. Measuring case-head to bullet ogive OALs of the five subsequently 48gn loaded examples with the comparator saw a 0.002” increase over 47.5gn and lower charges due to the compressed charge pushing back on the bullet base – not an issue as that’s a very small increase, was uniform and, with the COAL set at 20 thou’ off the lands, there wouldn’t be any pressure effects from this small reduction in jump. Weight spread and increments were as for N555, but here with 45gn selected as the starting charge before two full grain increments then two half-grain steps.

Results (Figures 1 to 4)

The trio uniformly lived up to what it says on the tin – ‘high energy’, with maximum load MVs comfortably exceeding my 2,800 fps target: 2,839 fps (N555); 2,863 fps (N560); 2,845 fps (N565). These are nothing spectacular these days with 260 Rem and 6.5 Creedmoor MVs approaching 2,900 fps regularly claimed on shooting forums but, they’re more than enough. None produced any pressure signs (hard bolt lift and extraction, ejector slot marks on the case-head and suchlike). The SPR has a fat, very rounded firing pin tip and is prone to primer extrusion and cratering with stiff but not excessive loads. The only load that produced any such indications was the top N555 charge of 44gn and it was ‘mild’ – but primers are a poor way to quantify pressure levels with visible pressure symptoms being dependent on primer make, model, and sometimes even production lot.

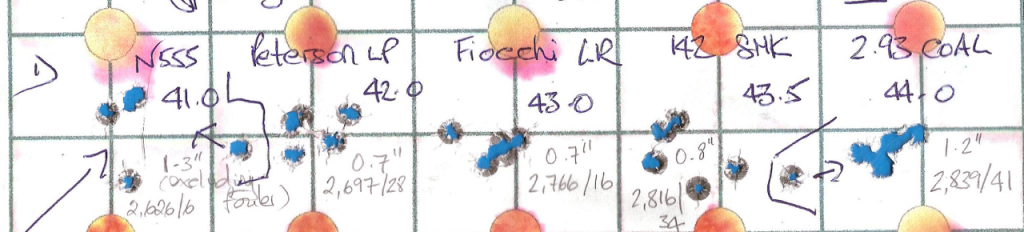

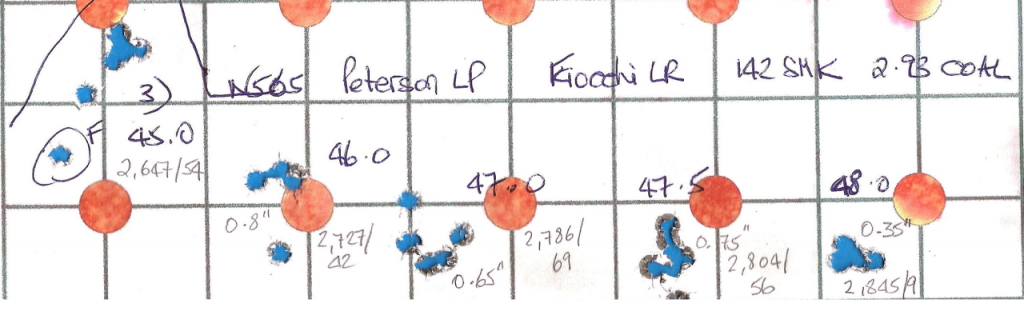

Note charges are written in above or alongside groups in ink on the target scans and group size plus average MV/Extreme Spread values alongside or underneath in fine pencil.

N555 (Figure 1 above) produced around 70 fps MV increase per grain of powder, very much what I’d expect and consistent without any worrying ‘spikes’. Results on the paper were so-so, the best three what I’d expect from the finicky FN at a consistent if mediocre 0.7 to 0.8” suggesting this isn’t one of the few really compatible powders that produce harmonics the rifle likes. Extreme spreads were also nothing special ranging from an excellent 6 fps to a poor 41 for the heaviest charge.

N560 (Figure 2 above) also acted consistently in the MV to charge weight relationship, but with larger values equivalent to 87 fps per grain powder. This is high but not unexpected with near maximum charges of this ‘hot’ powder grade. At 0.45 to 0.8-inch group sizes across all five charges it was the most consistent of the trio in this respect – but then it should have been given the small 0.3gn steps throughout. The one sub half-inch group was welcome but had more elevation in it than I would accept. MV spreads were worse than N555’s at 15 to 56 fps, less consistency than the groups represented. Still, with some load tuning and maybe experimentation on bullet seating depth, primer make etc, there was maybe just some hope of getting a salvageable result from more work – or then again, just more barrel life used up for little improvement.

N565 (Fig 3 below) started off at a low 2,647 fps from 45gn and rose by a consistent (and very comforting to those prone to nerves) 65 fps or so per grain of powder, absolutely ideal. The FN produced its three-quarter inch group standard yet again for the first four charge weights but ES values were worse, much worse, at 54, 42, 69, and 56 fps. Every group conformed to the four plus one pattern, the outliers all elevation fliers – 45 and 46gn odd man low; 47gn: high; 47.5gn: both ways! This I could understand as it was likely that this very slow burner was producing low pressures with these charges and my experience of Viht N500-series powders is that they need to exceed 50,000 psi to perform efficiently. Nevertheless, my spirits had dropped after three hours of shooting in a dark, raw, drizzling Pennines day with not a great deal to show for it.

My expectations for the final (48gn charge) group were accordingly limited, especially as the light was now fading rapidly despite it being only early afternoon on this late October day and I didn’t bother to look where shots were going until after number 4. My initial reaction was concern/surprise – I couldn’t find them! Misses? Blow-ups? Aiming at the wrong mark? These thoughts briefly ran through my mind before a more thorough ‘scope-search turned up a single enlarged hole! It didn’t show up well as the bullet holes had lost the surrounding black ring that accompanied earlier shots and the ambient light was really poor now.

The final shot thankfully also went into the group giving a centre-to-centre third inch or fraction more. ES values of 69 and 56 fps for the previous two charge weights collapsed to an excellent 9 fps. Recovering the target, the good news kept coming – very little elevation, nil in fact for four out of the five. Given a stiff, gusting crosswind, that third inch might even have been a trace smaller in still conditions but, let’s not question miracles when they occur! Nevertheless, I won’t put out the bunting in celebration quite yet as the FN has fooled me before with small one-off groups that refuse to be replicated at a later date. Thanks to Lockdown3, I won’t be able to retry this load and small charge increments around it for some time either.

Bonus 4th

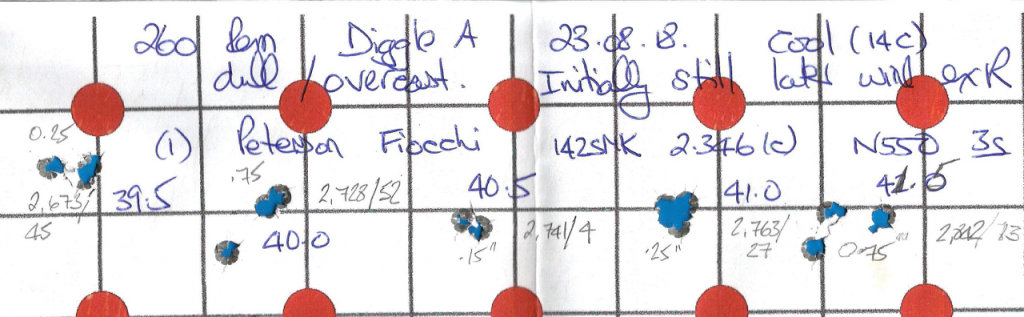

I’d used a fourth N500 grade a full two years earlier in my initial load development, so I’ll share that too (below). Again, Peterson cases (then new on their maiden use), 142gn SMK at the same COAL, and Fiocchi primers but only three-round batches loaded in half-grain weight steps. This was with long established N550, also from a fairly elderly (2012) lot.

The first thing I found about N550 was a significant discrepancy in maximum charge weights between those calculated by QuickLOAD and those on Vihtavuori’s website for the nearest equivalent bullets. Using fireformed Lapua case capacity, (as I hadn’t previously shot any Petersons), QL said that 43.6gn N550 would produce 57,829 psi / 2,865 fps, whilst Viht’s maximum values ranged from 38.4 to 40.1gn for the nearest equivalent bullets to the SMK. Even after allowing for the 1gn latitude gained from the extra chamber freebore, that’s a worryingly large discrepancy. (In the event of course, the Peterson cases turned out to have lower capacity than Lapua reducing the usable maximum charge too).

After mulling this over, I went for a maximum of 42gn – working up in half-grain steps and taking a QL ‘Charge Variations’ print-out with me to the range to compare actual MVs to QL-calculated – and look for over-pressure signs on case-heads very carefully after each shot. Actual MVs were indeed higher than predicted and the penultimate batch (41.5gn) saw 2,842 fps on the LabRadar. Adjusting inputs for the Peterson’s lower case capacity (which increases pressure / MVs), QuickLOAD calculates 53,491 psi / 2,795 fps MV so the actual result still ran 47 fps higher than predicted. Although there were no pressure signs at 41.5gn, the three cartridges loaded at 42 went home unused and were pulled. So when you read on forums or are told on the range that Viht reloading data charge weights are always WAY understated, don’t be too sure of that – better still ignore it!

Putting that to one side, you can see that N550 is considerably faster burning than the next in series N555 with a significant difference in top loads in this and similar applications, up to 4gn in Viht’s 260 Rem data. I was also alarmed to see how N550’s MV change to charge weight change ratio picked up from a not atypical 68 fps increase between 39.5 and 40.5gn charges to a worryingly high 101 fps for the next full grain. I’ve had previous experience of this powder producing pressure spikes as you approach maximum pressure in equivalent size cartridges, so this was another reason to leave the last batch in the box unfired.

Nevertheless, 40.5 and 41gn produced promising groups at 0.15 and 0.25 inches respectively, (remember, only threes though!), the former with a very low 4fps MV extreme spread. Their MVs are 100 fps down on what the slower burning N500s produced, but I could live with 2,750 fps. An N550 revisit with a range of charges in five-round batches joins more N565 testing with the 142gn MatchKing on my ‘260 Rem to do’ list in the finicky FN.

IMPORTANT NOTICE

These components and loads performed safely in the author’s rifle: this cannot be guaranteed for other firearms. Note especially the pressure-reducing effects of the additional chamber freebore in the author’s rifle and maximum charges quoted should be reduced by at least 1gn for standard chambers. Good handloading procedures should be used working loads up in small steps from the starting loads in Vihtavuori’s factory data while looking for signs of excessive pressure.

Peterson Cases

Peterson Cartridge Co. (www.petersoncartridge.com) is one of a group of new American rifle cartridge case manufacturers which have appeared recently to challenge existing manufacturers. Alongside Peterson we have ADG, (Atlas Development Group), Alpha Munitions. Also, Starline which has made pistol cases for many years has moved into mainstream rifle models in a big way. Peterson has obviously entered the premium end of the market to challenge the existing European quality brass producers for US sales as well as making speciality cases for ELR rifles. These 260 Rem cases represent my sole experience with the make and were bought mail order from the very efficient Dauntsey Guns a couple of years ago. As well as making a growing range of match quality cases ranging from 6BR/Dasher to 408 Cheytac, Peterson is also notable for making some designs in both standard large primer/2mm flash-hole and small primer/1.5mm F-H versions. 260 Rem is one such, but the SP option would be of little use to me as the FN/Winchester M70’s firing pin in my rifle is far too large diameter to cope with SR primers invariably cratering/‘blanking’ their cups at well below maximum loads and pressures.

Peterson cases are normally sold in 50s and come in a robust hinge-lid ammo box that saves you a few pounds. Appearance and condition are superlative out of the box and care has been taken to protect them in transit from factory gate to final customer with a thick foam lining in the box lid and a sheet of paper on top of the cases that has been impregnated with some sort of corrosion inhibitor.

I mentioned in the main text that they’re heavier and have a lower capacity than Lapua. I’d recommend dropping charges by at least half grain for loads worked up in the other make and 1-1.5gn if switching from Remington. How about other measures? Using 50-case samples, the Peterson weight range is larger than that of Lapua with a 3gn spread compared to 1.3gn. Measuring neck thickness at three points gave very similar results for the pair: typical thickness between 14 and 15 thou’, Lapua closer to the top of that range, Peterson the bottom; variations around the neck ranging from nil to just over one thou’ with around 60% of both falling within the excellent nil to 0.0005” band; both producing a single example around 0.0011”on samples of 25 (Peterson) and 30 (Lapua) cases.

One final point to note is case-head hardness – which determines how long cases last before expansion produces slack primer pockets. Lapua has a well deserved reputation for cold work hardening its lower bodies and the head/web area to maximise life with full-pressure loadings, some other makes aren’t so good and are regarded as ‘soft’. Peterson appears to have taken this message to heart. First, most buyers find that the pockets on their new cases are very ‘tight’, some complaining they can hardly seat some makes of primer. This is intentional, Peterson dimensioning them at the lowest usable diameter. Irrespective of head-hardness, stiff loads in modern high pressure cartridges inevitably cause some expansion on each firing. You can’t stop that short of loading to 19th century pressures but, if pockets start at the absolute minimum size they have to expand more before primers become a loose fit – ergo, another couple of loadings all other things being equal.

Then, I was struck by the headstamp area and lettering size, not to mention stamp depth. It looks as if the case-head may have been double-stamped. This matters because such stamping further work hardens the case-head over that imparted by the original swaging operations. Harder head equals longer life, simples! Whether this works, I can’t say with only two or three firings per case so far, but the make and its steadily growing range has been on sale, and successful, in the US for a few years now and these cases garner much praise on forums like Accurateshooter. Cost? When I bought my 50 from Dauntsey Guns they were slightly cheaper than Lapua 260s, but most of the few UK suppliers that a Google search threw up now want a substantial premium over the Finnish equivalent.