REACH OUT! – EU COMPLIANT POWDERS – Part 2

WARNING

The load data contained on this site is intended for use with specific rifles and components. Other manufacturers equipment will not produce equivalent pressures or velocities. Data contained herein is therefore advisory only and not intended for use by individuals – even those who are familiar with correct and safe handloading practices and procedures.

Target Shooter has set out not to produce reloading data but rather to offer alternatives to powders now unavailable due to REACH controls and it is up to the reader to interpret this data to suit his or her requirements and thus no responsibility is assumed in the use of this data. The information is to be used at the sole discretion of the user and the user assumes all risk.

The Fab Four

Having set the scene, let’s get on with possible replacements for the first of the ‘Fab Four’ – H4350. This slow burning propellant has been around a long time, or at least the original IMR version has, introduced by the DuPont Corporation way back in 1940. Reputedly this was to allow the 300 H&H Magnum, (which Americans had only recently discovered), to realise its potential. True or not, it certainly did give the belted Brit a massive hike in MVs, likewise transforming the contemporary performance of 257 Roberts, 7X57mm Mauser, 270 Winchester and even the ubiquitous ex-US military .30-40 and .30-06 Springfield numbers when loaded with heavier bullets. IMR-4350 was the slowest burning smallarms propellant available at the time by some margin and the first ‘magnum powder’, much loved by America’s post-war ‘wildcatters’ and experimenters like P.O. Ackley.

Hodgdon Powder started as a small outfit selling bulk propellant lots left over from WW2. It wasn’t until 1982 that it got its own new-manufacture version of this now mainstream grade, initially sourced from ICI Nobel in Scotland, later moved to ADI in Australia after Nobel’s demise. Today’s version still comes from there, but in a much refined shortcut and ‘Extreme’ temperature-stable form. (Ironically, Hodgdon Powder now owns IMR and contracts with General Dynamics’ Valleyfield operation in Quebec, Canada to produce its one-time competitor.) There is a third ‘4350’ to be found, Western Powders’ Accurate-4350, also made by GD in Valleyfield – we don’t see it or any other post-2001 ‘Accurate’ brand powder here. Finally, there is an earlier 4350 with a similar name, and we did get it here – Accurate Arms Co-XMR4350. It survives under a couple of brand and product names – Lovex SO70 for us in Europe and Shooters World SW4350 in the US. We still have it, and it’s the sole Reach-compliant ‘4350’ of the quartet.

Choices, Choices!

Using my 7mm-08 chambered Savage 12 PTA-based F-Open rifle as the test rig, the first step in the exercise was to identify a benchmark H4350 load and a range of possible alternative propellants. The 7-08 is at the lower end of the ‘case capacity to bore’ ratio range of suitable cartridges for the 4350s, but these and other mid to slow burning propellants work just fine in it when loaded with heavier, that is above 140/145gn, bullets. It’s a very flexible little cartridge and loading manuals provide data for a wide range of burning rate powders from IMR-4166, Alliant Reloder 15 and Hodgdon VarGet to Alliant Re19, Ramshot Hunter, and IMR-4831 with 160-168gn bullet weights. The faster burners sometimes pick up the ‘most accurate load’ accolade where this is provided. However, their maximum charge weights, case-fill levels, and top MVs are usually a step lower than those for powders with optimal or nearer optimal burn rates such as H4350. For example, 45.0gn is around maximum for the H4350 and my favourite bullet in the cartridge, the 160gn Sierra TMK. That’s according to Sierra, Hodgdon, and QuickLOAD, whilst the faster burners top-out at 39-40gn hitting maximum peak pressures there, and MVs are reduced accordingly, with the possible exceptions of Alliant Re15/Norma 203-B. So, the objective was to identify and try powders that have maximum charges of around 43 to 47gn in the combination, ie H4350’s maximum plus or minus 2gn, whilst producing similar or higher MVs.

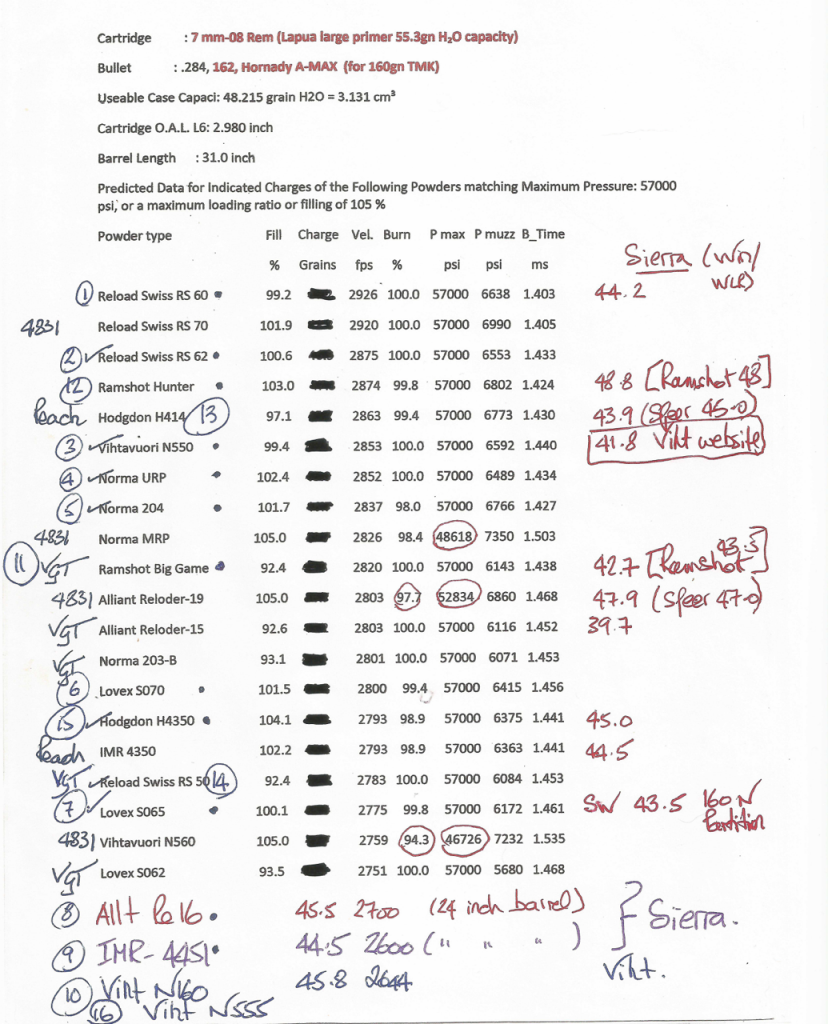

Step 1 was a QuickLOAD Charge Table run with the measured fireformed case ‘overflow water capacity’ using Lapua brass and the 2.950” COAL as set to just short of the lands input into the program. Output parameters were set to 57,000 psi maximum chamber pressure (a little below typical factory loading levels) and/or a ceiling of 105% calculated fill-ratio, ie mildly compressed. (Note, the rifle has a ‘minimum SAAMI no-turn neck’ match chamber, and more pertinent here, around 150 thou’ more ‘freebore’ than a standard factory rifle, the chamber having been throated-out to see the COAL at 2.995” with a 168gn Berger VLD just kissing the rifling lands. That near two-tenths inch addition to the SAAMI 2.800” nominal COAL sees maximum charges increased by around 1.5gn depending on powder characteristics to produce comparable pressures with the same case according to QuickLOAD.)

The QuickLOAD output was pasted into a Word document and purged of unavailable and inappropriate powders, also generally ‘cleaned up’ –

Because my QuickLOAD version is elderly, it lacks several recent bullet and powder introductions, the former including my chosen model, Sierra’s 160gn TMK (Tipped MatchKing). The similar length and shape 162gn Hornady Amax was substituted, and experience has shown this to work well in the model, very well indeed with some powders. Note QL’s calculated charge weights have been redacted for various reasons – this function is designed to allow powder comparisons rather than provide usable loads.

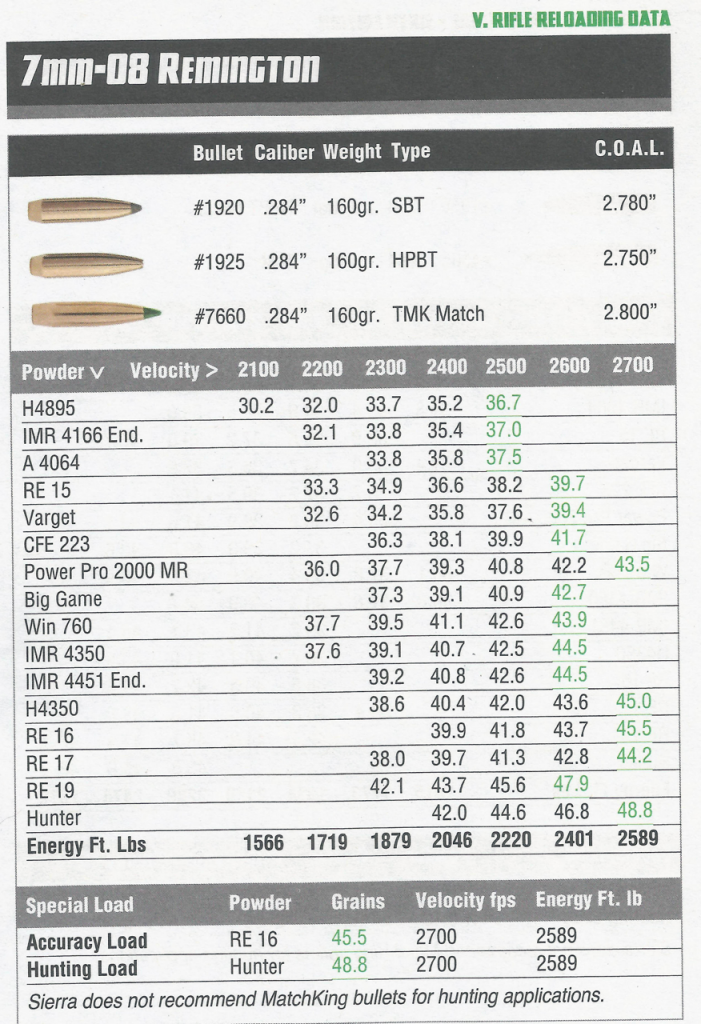

Manufacturers’ data for these powders were then ferreted out from various sources, printed and online, to compare to the QL results. Sierra’s latest manual, its VI edition published in late 2019, was particularly useful here with up to date loads for its three 160s including the TMK and a couple of the powders that are absent from my version of QL – Alliant Reloder 16 and IMR-4451 Enduron

That gave me QL loads for 12 powders including the two Reach-ban Hodgdons, H4350/414, and max loads from Sierra 6th Edition and Viht’s website written in underneath. My scribblings, sorry notations, are all over the page. ‘4831’ and ‘VGT’ on the left of the powder names means that they’re better suited to the H4831 or H4895 / VarGet exercises, so won’t be used here. Where available, max loads from manufacturers’ sources are handwritten in to the right, mostly from Sierra VI. You’re maybe wondering why there is no QL output line for Viht N160 and 45.8gn for the 160gn Sierra BTSP has been taken from the manufacturer’s online table and handwritten in? That’s because I won’t use QL for this grade as it seriously underestimates pressures and therefore overstates usable charge weights. N550 is only slightly better hence Viht’s top load written alongside that line and surrounded by a ‘box’ to remind me of the difference.

Otherwise, QL v manufacturer maximum values vary from having remarkably little difference up to around 2gn divergence – and not all higher for the computer model either. Our benchmark H4350 has a QL max of 45.3gn against the Hodgdon Reloading Center and Sierra VI agreed figure of 45.0gn. That’s despite the program factoring in the significant (pressure reducing) internal ballistics effects of the longer chamber / COAL. So, isn’t there a mismatch here? If, as I’ve just said, the long freebore sees charges increased by around 1.5gn to produce similar MVs/pressures, then logically the loading manual maximum should be reduced by that amount, to maybe 43.8gn for its 2.800” COAL loads matching the short SAAMI chamber. One set or the other has to be wrong, surely?

Actually, they’re both correct as best I can tell. There is a second difference between my test loads and Sierra’s/Hodgdon’s – the cartridge cases used and their internal capacities. Sierra uses light / high-capacity Winchester cases and Hodgdon the slightly lower capacity R-P equivalent in their test barrels. I loaded heavier, lower capacity Lapua cases. (I use Winchester 7-08 brass in one of my loads so know its water capacity – 57.0gn compared to Lapua’s 55.3gn after firing in this rifle. Rerunning the long-COAL cartridge in QL with that higher value increases the model’s H4350 charge weight to 46.5gn at 57,000 psi, so one can see the two competing effects have largely cancelled each other out.) Nevertheless, in this instance, I used the still slightly lower Hodgdon / Sierra 45.0gn figure since it’s close enough to the calculated QL/Lapua case value and the exercise is about comparisons, not maximising 7-08 match load MVs. (It is however an excellent illustration as to why you shouldn’t swap charges worked up in one set of components to another any old how!)

To summarise, when I reached the loading and testing stage, I had two Reach non-compliant benchmark grades, H4350 and H414; thirteen Reach-compliant possible alternatives (two ball-type and eleven extruded/tubular); one faster burning addition for comparison lifted from the H4895/VarGet alternatives list, for a grand total of sixteen powders. All potential alternatives are also available in the US with the exception of two Reload Swiss grades, one of which is the faster-burning ‘freebie’. If they’d been limited to five 3-round groups, that would have entailed loading and shooting some 80 batches/groups for 240 rounds. However, as some were given more batches, and a few groups contained more than three shots, the final aggregate round-count was higher at somewhere around the 300 mark.

Bits & Pieces

Before getting to what the targets and chronograph say, brief coverage of the equipment and components used. The rifle is a budget custom job based on a Savage Model 12 ‘PTA’ single-shot target action which I’ve owned from new. It and its Accutrigger assembly are exactly as they came out of the factory, but they are now on their second stock and fourth barrel / cartridge. Metallic Silhouettes competition aside, 7-08 isn’t an oft-seen cartridge in match form, but back in 2014 I wanted a high-precision short to mid-range F-Class tool with better barrel life than the 6mmBR Norma or most 6.5s. So, it was rebuilt into its current form by Dolphin Precision with an F weight 31-inch 9-twist Bartlein that Dolphin fluted in-house. The rifle in this guise has always performed well, but the ‘mid-range F’ role has now gone thanks to a steady increase in club-level shooting standards accompanied by an ‘F-Class arms race’ over recent years. I now mostly use it for 300 yard comps.

The test cartridges used 100 new Lapua standard large primer cases, elderly PMC LRM ‘magnum’ primers and the 160gn TMK seated out to 2.95” to match the chamber, the ogive originally 15 thou’ off the lands, likely more now after 2,000 plus rounds down that barrel. A strange and heterogeneous collection of tools and loading practices put the bits together using both Wilson inline dies on an arbour press and conventional models with my Co-Ax press. The Lapua brass was used as it came out of the box apart from initial mouth chamfering and a pass over a neck-expander mandrel. Test load powder charges were mostly dispensed by an RCBS Charge Master then check-weighed on a set of Acculab scales and adjusted if required. ‘Magnum’ primers in this modest cartridge? The old Russian PMC LRM (Murom KVB-7M is today’s equivalent), is a milder cap than many standard models and I’ve used it successfully with the 7-08 throughout. (I have a lot of them too which helps!)

Results

One final bit of scene setting. Targets were a free mytargets.com downloadable design, the inch square grid with four lines of red half-inch dia. aiming marks. Printed on 120gsm A4 card, they were mounted on the target frames in landscape mode. This not only displays group sequences clearly, but also shows how well they maintain elevations against the nearest horizontal grid line. Combinations that produce groups that climb, drop, or jump around at 100 yards as charges increase don’t produce stable nodes at longer distances – thank you Erik Cortina for that tip. A Labradar chronograph was used. With a few exceptions, groups were three-shot – less than ideal, but more rounds down the barrel would have created intolerable component and barrel wear costs, more barrel heating hence more frequent cooling off periods.

Most powders had five groups, but more were used for a few, either for my own edification or because there was uncertainty about maximum load levels and I did an extra-cautious work-up in smaller steps. No pressure problems were encountered with any load combination tried, and no cases were retired early – bar one which turned out to have a shoulder crease when cleaned after the first firing, a rare Lapua production fault.

Reports

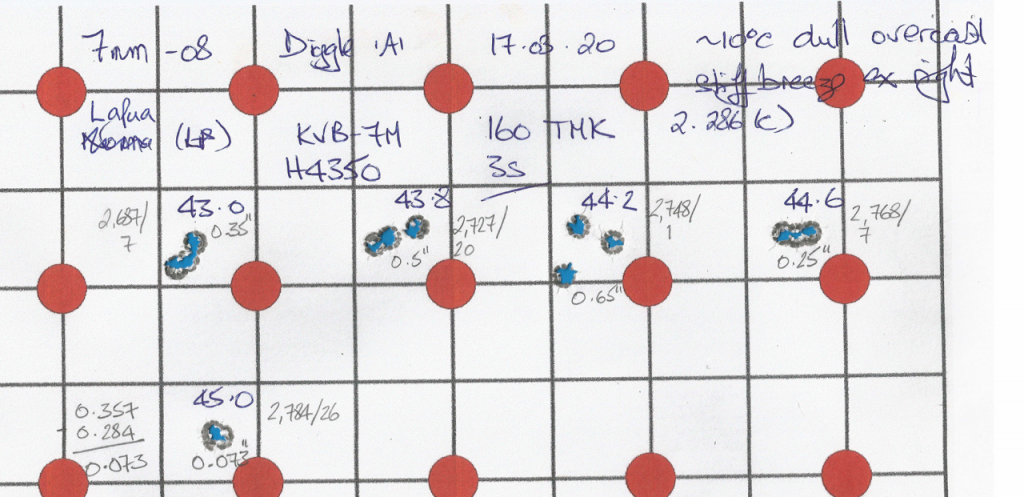

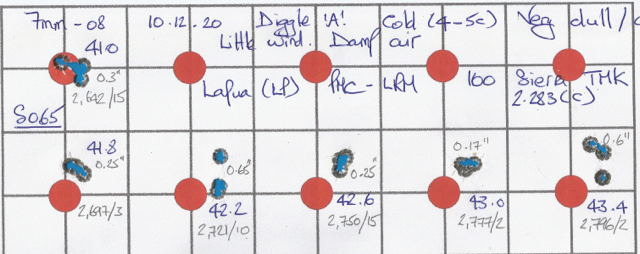

Having given some thought as to how to show the results, scans of shot targets are being used with group sizes and MV / ES values pencilled in. The charge weight is above in ink. Then I wondered about their order – by results, marque, chronologically, or whatever. In the end I settled on grouping them according to my interpretation of results on the paper, a bit like a school end of year report on pupil groups. But first, let’s see how our primary benchmark grade, H4350, performed.

The first three groups were nothing special MV or size/shape wise, but then lost the elevation spreads on #4 at 44.6gn and 2,768 fps. As there was a gusty crosswind on the range, it might have pushed one shot out a tad from an even smaller group, but we’ll live with quarter-inch. The final (45.0gn) group was however, a true one-holer. I usually made a quick and dirty size measurement rounding the result up to the next 0.05” (half-tenth). In this case I got the callipers out and did a proper job to three decimal places before calculating the centre-to-centre value at 0.073”! I had mixed feelings about this. On the one hand I was delighted that our benchmark grade had done so well. Against that, I thought: “Damn! This is going to be hard to better or even match.” MV at 2,784 fps was where QuickLOAD predicted (2,778 fps for 55,902 psi PMax). So, in my long-throat chamber, charges could potentially have been raised a bit if c. 60,000 psi (SAAMI maximum) higher-MV loadings were required. Note though, that the charge weight that produced the tiny group also increased MV spread from single figures to 26 fps. I don’t know how often I’ve seen this in a variety of cartridges and powders!

For British readers, note the date on the target card – 17th March 2020, days before a panicked UK government imposed a strict Covid lockdown. My next testing session was six months later on 1st October!

‘Shooting Stars’

My first alternatives group is for those grades I judged ‘star performers’ in my rifle: Reload Swiss RS62, Viht N160, and – this may be a surprise to many – the much underrated Lovex SO65. (Shooters World ‘Long Rifle’ in the US.) I also threw in a gratuitous Varget-equivalent freebie tried to see if the faster burners do perform as well as some manuals show, in this case Reload Swiss RS50, an untemperamental single-based grade that is rather slower burning than the Hodgdon superstar, closer to Alliant Re15’s level.

If I’d been asked in advance which alternative grade I’d put my money on, it would have been Reload Swiss RS62. I knew from previous use in 260 Rem and 6.5mm Creedmoor that its performance is close to those of IMR-4451 and H4350. It is a longish-grained tubular single-based type, predictable in its performance and performs consistently over extended use in all northern England conditions. It slightly outperformed its QuickLOAD predicted performance, 45.0gn producing 2,802 fps MV compared to the calculated 2,772. If QL is to be believed, it does so with less pressure than H4350 needs for these speeds. With five groups running from 0.15 to 0.3” C to C and MV spreads barely hitting double figures, what’s not to like? I’ll try follow-up 5-shot groups covering 44.6-45gn for use as a match load. With 45gn H4350’s 2,784 fps achieved by ~44.6gn RS62, it may be a little faster burning than the Hodgdon/ADI grade, but it is a higher energy powder and that alone could account for this small difference.

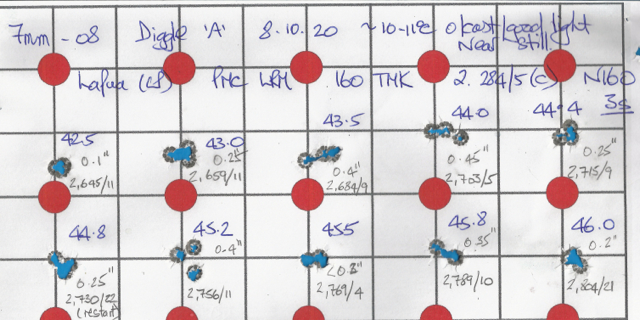

I’d expected N160 to put up a good show given that I’d selected this grade from load development in the barrel’s early days and ended up using it with this bullet as my main match load. That however, is in necked-down Lapua 308 Win small-primer ‘Palma’ brass. Now in the large primer version, with no fewer than 10 groups covering a 3.5gn charge weight range running from around 0.1 to 0.4” and mostly modest MV spreads, this 2017 lot of Viht’s mild powder performed well. In fact, it performed better than my SP-brass version in all aspects bar MVs, this test topping out at 2,804 fps with 46.0gn. Further five round groups based on and around 45.5gn will be tried for future match use. At 2,769 fps, this is nearly 100 fps down on my small primer case very hot compressed-charge loading, but as the rifle has lost its 600 yard F-match role, that is of little matter.

Despite one rationale for SP ignition being small velocity ES values, the PMC LRM figures I obtained here are substantially better. Food for thought! Note that group #4 and subsequent groups lifted by around half-MOA compared to the first three. The five groups on the lower line (44.8-46.0gn) stay pretty well right on the grid line across the page, only moving a shade right with higher pressures and MVs. Incidentally, for those who take it as an article of faith that Viht’s maximum loads are always low pressure, the company’s 45.8gn N160 with same weight Sierra GameKing BTSP – but at only 2.776” COAL in the same heavy Lapua brass must be a ‘warm’, not to say extremely ‘hot’ loading in a standard short CIP/SAAMI 7-08 chamber! H4350’s 45gn 2,784 fps MV was achieved at around the 45.7gn N160 mark, so unsurprisingly, this is a slower burning powder – but by nothing like as much as burning rate charts suggest.

Lovex SO65 got off to a bad start in the UK after its introduction some ten years ago, and has never recovered the lost ground. The problems stemmed from Explosia’s burning rate chart which positions this grade alongside VarGet. The UK distributor unsurprisingly sought to capitalise on this bit of apparent good fortune, especially as we were then suffering a protracted Hodgdon powders ‘supply drought’. Sadly, this didn’t turn out well – people who tried SO65 in classic ‘VarGet cartridges’ such as 308 Win and 6mm BR obtained poor results. A look at Explosia’s 308 loading data soon explains why. This contains loads for a creditable range of 15 bullets from the 147gn S&B FMJBT up to the 200gn Norma Oryx. Every one of the 15 SO65 top loads is shown as compressed! Six fail to achieve 50,000 psi, the lowest a pathetic 44,700 psi. Of the others, most are in the low 50,000s, only two achieving standard 308 Win pressures of 57,300 and 58,200 psi, and one of them is for the 200gn Oryx.

The powder is simply too slow burning for this and similar applications – with most bullet weights you can’t stuff enough into a 308 Win case to achieve full pressures even with heavily compressed loads. Look at the company’s tables for larger case, smaller bore cartridges like 7X57mm and 7X64mm, cartridges normally associated with the 4350s, and pressures are now normal with satisfactory MVs. Explosia doesn’t provide data for the 7-08, so I relied on QuickLOAD here, working up to 43.5gn which was predicted to give 100% case-fill, 2,774 fps MV / 56,923 psi PMax and a near 100% charge burn in my set-up. In the event, that charge weight produced a bit more velocity, 2,796 fps which equates to around 58,500 psi. (Reduce that 43.5gn maximum by at least 1.5gn for standard short-freebore chambers!) So, it is a quicker burning powder than H4350, 43.1 or 43.2gn matching the latter’s 45gn for 2,784 fps, but still nowhere close to VarGet whose maximum load would be around 41gn in my long-chamber set-up and is listed by Sierra as 39.4gn maximum for the 160 TMK in a standard SAAMI chamber.

Six batches were loaded up for this grade, and four produced small groups from under 0.2” to 0.3”; the other two vertically strung, two plus one efforts approaching two-thirds inch. There seemed to be nodes for either type recurring at 1.2gn charge weight intervals. A good stable small-group node appeared to lie between 42.6 and 43.0gn, so I took a punt on the latter charge, and loaded up 50 rounds for 300 yard matches. I’ve only competed in one such match since, and it performed very well with almost nil POI elevation spread. Also encouraging, the original tests took place in winter at 4 to 5-deg C whilst the match was on a hot (by Diggle standards) summer afternoon that would have seen well over 20-degrees on the firing point. I wasn’t surprised – I’ve used this powder obtaining excellent precision since the rifle’s early days when paired with Winchester brass and the Lapua 150gn Scenar-L. Shooters World in the US recommends this powder under its US ‘Long Rifle’ moniker highly for the Creedmoors. I’ve not tried it in the 6.5 version, but could readily believe it’ll work well in this cartridge.

Around the time that Lovex SO65 appeared, Nigel Cole-Hawkins, an entrepreneur who is also an avid Match and Target Rifle competitor began importing and packaging a Swiss powder he’d named TR140. There were no loads data, just a recommendation to use Vihtavuori’s N140 starting loads and work up – hence the name (allied to TR for ‘Target Rifle’ shot only with the 308 Win in the UK). With it priced at £55 per kilo, Nigel did well, so well in fact that its manufacturer Nitrochemie Wimmins A.G. decided to set up a UK operation for the entire large RS range doing the bottling itself back in the factory, and to market these powders under its European retail branding, ‘Reload Swiss’. TR140 is still with us as RS50, but sadly no longer for £55 a tub. Nigel’s relationship with Nitrochemie continues and prospers as he created and runs the RS UK distribution and marketing arm.

TR140 was a well chosen name as its performance and loads are indeed similar to those for Viht N140. It is slower burning than VarGet in most applications, and is a key player in my next test series for that product’s alternatives. I reckoned it fitted the bill for trying a faster burning grade in the 7mm-08. The problem then became loads. Propellants.co.uk, the UK Reload Swiss website does have data for the cartridge, but with a very low 31.8-37.3gn RS50 range listed using Nosler brass and the 162gn Hornady AMax. Even with the chamber length issue and my 1.5gn or so ‘fiddle-factor’ for the 2.95” COAL/long chamber, that’s a maximum of under 39gn in my rifle. QuickLOAD came up with charges that are … ahem …. a trifle heavier. Having used the powder in many cartridges and combinations and got a ‘feel’ for it over a decade of use, I disregarded both and reckoned 40gn or a little above would be about right. In the event, the trio of 39 to 40.2gn test charges showed no pressure signs at all, produced quarter-inch or smaller groups, and ES values of 2 to 4 fps. 40.2gn’s 2,710 fps was well above QL’s prediction of 2,645 fps (at 47,820 psi PMax), so actual pressures had to be considerably higher too. A bit of fiddling with the program produced an estimate of just over 52,000 psi to produce this velocity with the powder in my set-up, still very modest if it’s correct.

When loads manual compilers mark a combination as ‘Most accurate load’ or some such, what they usually mean is that this is the combination that gave the smallest MV and pressure spreads – ie the most ballistically consistent combination. With a 0.1” 3-shot group and ES of 4 fps, 39.8gn RS50 may have been my ‘most accurate’ load of the entire project, but note that the MV is 100 fps down on the benchmark H4350’s, and more than 200 fps down on some other optimal burning rate powders I tested in the exercise. I don’t recommend this combination, rather included it as an interesting excursion as most loading manuals include 7-08 data for equivalent grades such as VarGet and Reloder 15. Personally, I’d choose its slower burning stablemate RS62 any day. (It will figure strongly in the H4895/VarGet tests using 223 Rem and 77gn SMKs.)

Even though I’ve only covered five out of my 16 powders, this section is now big enough to be getting unwieldy. So, give me and Target Sports a few days and the final part of H4350 alternatives will follow with target scans, results, and commentary for the remaining eleven powder grades. To give you a flavour of how they turned out, they’ve been grouped as ‘Speed Kings’; ‘Shows promise / needs more development’; ‘Little Balls / Large Groups’; and ‘The Snail’.