Components Shortages and Substitutions

Much recent talk on the ranges and shooting blogosphere has been about component shortages. Happy is he or she who bought 10 years worth of brass, bullets, and some makes and grades of powders and primers before the great drought started! As a new season opens, some British handloaders are maybe only now becoming aware of the nature of the problem as they trundle along to their local gunshops and ask for half a dozen tins of VarGet and 500 7mm Berger Hybrids! Assuming any such innocents actually exist, they’ve obviously not visited many online forums which have been peppered with plaintive ‘wanted’ posts for favoured powders, primers, and projectiles since last summer. Note, I say ‘favoured’ as there is nothing like an absolute components drought, rather shortages of those that offer a real or perceived competitive advantage or fit a particular niche particularly well.

What’s behind all this, and more relevantly, when are things going to get back to normal? The simple,(some would say simplistic), answer is that it’s entirely a result of US shooter antipathy to and fear of ‘anti-gun’ President Barak Obama and a burgeoning federal bureaucracy desirous of instituting ‘European socialist’ type policies and regulations / restrictions. In this scenario, these fears fed on themselves in the aftermath of the Sandy Hook school shooting and Americans are still hoovering up every last box of bullets and 1lb powder bottle that they get to hear about whether needed or not. If you’re American and believe your state or the Federal government are going to ban sales of semi-auto pistols and AR-15 type rifles, restrict ammunition holdings and handloading, regulate lead-core bullets out of existence etc, your bank balance or credit status are healthy, well what would YOU do? Unfortunately, the USA is not only the source of many of our handloading supplies, but also houses most of their consumers, so when the US goes short everybody else is in the same boat.

If this were all there is to it, shortages will abate sooner or later, although once panic buying takes hold it can be remarkably persistent, and have all sorts of perverse consequences. During my youth, some tabloid daily started a scare that a strike was going to create a national shortage of loo-paper. Even in those primitive days before we had the Internet and social media, rumours spread like wildfire exaggerated at every retelling and rolls of Andrex fled off store shelves despite rationing! Desperate measures and substitutes were sought: almost any paper product pressed into service. The purveyors of kitchen paper-roll, electric bread knives (to cut them in half), and plumbers who specialised in unblocking toilets probably still remember the resulting chaos fondly! In this case, there was no underlying supply shortfall, paper manufacturers worked overtime, and panic buying soon subsided.

Structural

And, in my view, therein lies the difference in our present predicament – for there ARE structural issues at least so far as powders are concerned. This is a direct consequence of our recent history after the end of the cold war. Western governments, the USA’s aside (and even it is now following the trend), have instituted massive defence cutbacks while privatising everything in sight. They’ve ruthlessly squeezed every last drop of savings out of the so-called peace dividend, and in my view for what it’s worth, compromised basic national security. Add in a general view amongst the political classes that state owned equals expensive / bad, procurement from private enterprise cheap / good and weld it onto the conviction that we’ve seen the end of major traditional military conflicts. In this fantasy world, private enterprise will supply everything the military needs at short notice in any and every conceivable future scenario.

Baseload demands for propellants and explosives are largely determined by government orders. The last quarter century’s huge cutbacks in the size of European standing forces, the end of national service requirements, disbanding of militias allied to reductions in exercises and live firing training for the surviving ‘regulars’ and reserves across Europe and Scandinavia have reduced orders and consumption to a minute part of what they were. Stored ammunition inventories are also tiny compared to cold war days only covering ongoing consumption with limited contingencies for emergencies. With production transferred to private ownership, reduced and highly variable order levels translated to downsizing and plant closures as no commercial operator keeps expensive spare capacity and skilled workers hanging around on the off chance of future orders.

There is another factor too – the ubiquitous health and safety overlay, all large industrial plants seeing tighter regulation in recent years, but especially affecting those that use, make, and store dangerous products. Recent history is peppered with shorthand names for major industrial accidents that started with a fire or explosion. In the UK: Flixborough (chemical plant detonation), Piper Alpha (North Sea oil rig fire and explosion), Buncefield (large oil storage depot fuel-air explosion followed by weeklong major fires) to name just three. Flixborough and Buncefield each wrecked hundreds of adjacent properties demonstrating that such plants need larger separation distances from other buildings than had been previously believed safe.

Most former government explosive manufacturing plants were decades old at the time they were privatised, had received little investment in modernisation and upgrades after WW2 ended. Their boundaries had often been encroached on by what can only be described as the outcomes of careless local planning permissions allowing neighbouring residential or industrial building. (The Buncefield accident report notes that the tank farm had been originally built with large separation distances, but the local authority had allowed subsequent commercial development immediately alongside – it was sheer luck that saw the initial massive fuel vapour explosion occur at 06.01 on a Sunday morning when these properties were unoccupied avoiding hundreds of casualties.)

Explosives manufacturing not only uses dangerous materials and processes, but generates unwholesome wastes, another factor that adds to operating costs given increasingly tough environmental and pollution regulations. The EC in particular seems to be obsessed with banning the use of long established chemicals that it now deems are particularly nasty, and what happened to many traditional farming and garden chemicals may shortly be repeated with some smokeless powder formulations. Not that this is a Europe-only problem. Handloaders talk in general terms about ‘American powders’, with IMR, Hodgdon, Alliant etc products coming to us from the land of the free. However, there is only one surviving smokeless propellant manufacturing plant in the whole of the US, the former Winchester / Olin Corporation factory at St. Marks, Florida now part of the General Dynamics group, and it only makes ball powders, or those based on the ball form.

So, what am I saying? I don’t think that shortages will be limited to the short-term. Even if I’m wrong and things return to normal soon – and I do hope I’m wrong – everybody in the propellants business says that handloading powders can only become more expensive.

Berger Expansion

Before we get too depressed about things, the bullet supply position is still mixed but improving. One major problem was Berger’s recent runaway success, such that favoured lines would have been in short supply even without any panic buying and hoarding. Berger Bullets has responded energetically to the situation dropping its less popular models to concentrate on those in greatest demand, simultaneously increasing its production capabilities. It produced 45% more bullets last year than in 2012, but is currently going further increasing the number of bullet making machines it operates from five at the beginning of 2013 to eleven later this year thereby more than doubling outputs over an 18 month period. It seems likely that our importers will gradually catch up on order backlogs, but it’ll probably be 2015 before supply and demand reach equilibrium.

Not everybody is happy about the changes to the company’s match bullet range, an example being the loss of the 90gn 0.224” Target Long Range BT leaving the Target VLD as the sole model in this weight. I know of several .223 Rem ultra heavy bullet shooters who much prefer the discontinued model as they cannot make the VLD perform consistently. Another casualty of the bullet drought has been a raft of new ‘Hybrid’ designs that had been developed to the point where samples were due to be issued to favoured shooters for in-competition feedback – the last step prior to starting full production – but all now on hold while Berger concentrates on increasing production of existing models. A 195gn 7mm Hybrid is probably the most significant casualty, many F-Open shooters desperate to see what this model will do, its performance likely to determine choices people face over sticking with a ‘seven’ or switching (as some have already done) to a .300 short magnum loaded with 215 or 230gn Hybrids. Berger says that it will resume work on introducing this and other new designs as soon as it catches up with its order backlogs, hopefully later this year.

Not all Bergers are unobtainable anyway. Many .308 Win users don’t like the company’s VLDs, so while you struggle to find the 185gn LR BT ‘Juggernaut’, likewise its 210g LR BT big brother, it’s often easier to get hold of 185, 190, and 210gn VLDs. Some weights are less popular than others too, especially in .308 with the 175gn LR BT nothing like as highly regarded as its 185gn sibling. Even the new 155gn Hybrid can sometimes be found, most F/TR shooters so happy with the older 155.5gn BT ‘Fullbore’ that they have no desire to change models even with a reasonable BC improvement. The word has got abroad that 168s are ‘bad news’ for the long-range .308 Win shooter, and while that’s true for older designs from Hornady, Lapua, Nosler, Sierra and Speer, it doesn’t apply to Bergers in Target VLD and Hybrid guise, the latter a superb long range high-BC model but discounted by most F/TR competitors – so you might be able to find some in stock.

‘Temporarily suspended’

Hornady has ‘temporarily suspended’ the majority of its product lines concentrating on making the big sellers. Most A-Max models are OK, but 52 and 80gn 0.224s and 162gn 7mm models were among the casualties, the latter much missed by many .284 Win users. Most of the company’s HPBT Match models, only introduced three years ago, also joined the ‘temporarily suspended’ camp, the longstanding short-range 168gn .30 and new high-BC 140gn 6.5 the sole survivors. The good news is that just as I was finishing this report, Hornady Manufacturing announced that a number of suspended models are going back into production. Hornady’s 2014 bullet production list is available here: http://www.hornady.com/assets/files/support/CurrentProductionList.pdf. The 162gn 7mm A-Max and equally good news, the more modern 162gn HPBT Match version, have been reinstated as have 52 and 53gn .0224” match models. Although not highlighted as a reinstatement, I notice that the 0.308” 178gn HPBT Match has reappeared to complement the older A-Max. The HPBT version is far superior to the A-Max design as a long range bullet and offers .308 Win F/TR and other shooters a cost effective alternative to some Bergers.

Hannams Reloading tells me that there are no supply problems with Lapua bullets, other than their disappearing out of the warehouse even quicker than in the past if they’re seen as alternatives to other company’s models in short supply. Stocks of the popular and very high BC 155gn .30 Scenar are good, but the more expensive supergrade ‘L’ version has sold out at the time of writing. I’m pretty sure that this was, initially at any rate, because of substitution for unobtainable 155.5gn Bergers. The good news is that Hannams continues to receive regular shipments from the manufacturer without any rationing or order shortfalls – this also applying to the company’s brass. Lapua, unfortunately doesn’t make any 7mm match bullets – but that gap is about to be filled and the three American suppliers of these products (Berger, Hornady and Sierra) will maybe get some competition from Europe at last.

That leaves Sierra. Shipments continue to be received, although usually without full quantities of the most popular models. The new model .30 155gn ‘Palma’ MatchKing (p/n 2156) often falls into this category although you’ll maybe find supplies if you telephone enough dealers. (As it happens, I noticed a small mountain of newly arrived boxes of these bullets in my friendly local Northern dealer’s premises just before submitting this piece, a new shipment having only just arrived from the US.) The older, lower BC (p/n 2155) model which has been stripped of its ‘Palma’ branding is usually widely available. Supplies of other old favourites like .30 calibre 168 and 175gn Sierra MKs are best described as ‘patchy’, although with so many dealers stocking this marque, a diligent search will likely pay off even if it involves expensive mail order carriage charges should your local gunshop be ‘out’. Many excellent bullets in other diameters are in stock, the high BC VLD form 180gn 7mm MatchKing for instance. Many top US F-Open competitors switched to this bullet from Berger VLDs for the F-Class World Championships in Raton last August and did very well with them. They do need a base to ogive length check using a comparator and some batching as there are often larger variances than with the Berger VLDs and Hybrids. Some MatchKing lines are only widely available in this country in 500-count boxes, 77 and 80gn .22s and the superb 107gn 6mm falling into this category.

6.5mm calibre bullets (other than those made by Lapua) appear to be hard to get at the time of writing, maybe down to growing American interest in the calibre and the recently introduced 6.5mm Hornady Creedmoor cartridge proving a runaway US success. Hornady 6.5s are usually ‘out’ – I’ve had no luck in getting hold of any samples of the recently introduced 123gn A-Max, for instance. I did manage to get hold of the same weight Sierra MK from Henry Krank a couple of months back though to complement the widely used 123gn Lapua Scenar.

The search for VarGet

“The search for ….. “ is a favourite line amongst fiction writers, journalists and historians, even philosophers. So instead of “Star Trek III: The Search for Spock”, here’s “Powder Trek: The Search for VarGet” Will Hollywood buy it? – probably not! Actually, it’s not just VarGet, as H4895, H4350 and H4831SC are in equally short supply with many desperate users trying to hunt up replacement bottles. Note, these are all Hodgdon brand propellants manufactured by Thales / ADI in its Mulwala, Australia facility.

Putting the discovery of someone with a generous disposition who holds some of these and will share or sell them to one side, what are the prospects for British shooters getting any this year? Frankly poor! There may or may not be some Hodgdon extruded lines that make it to the UK over the coming months, but the word on VarGet is a blunt “No chance!” I and many other regular Hodgdon users now assume there won’t be any of the company’s extruded (stick) powders arriving in the near future and are therefore seeking alternatives.

First, some clarification. When I say “Hodgdon powder non or short-supply”, that refers to the company’s Australian manufactured stick types: H4198, H322, H4895, Benchmark, H4350, H4831 and 4831SC, H1000, VarGet and one or two others. Other ‘H’ powders that are based on US ball powder manufacturing by the St. Marks Powder Co. should remain available. That’s CFE223, H335, BL-C(2), LEVERevolution, H380, H414, Hybrid 100V, and SUPERFORMANCE.

On top of that, Hodgdon provides the IMR extruded powder range manufactured in Canada and they will also still be available to at least some extent, hopefully in quantity, being used to fill some of the gaps in UK orders. So, you should consider IMR-4895, 4350, and 4831 as possible alternatives where you’ve used the Hodgdon versions and cannot find a resupply. It’s important to stress that they are NOT identical to the H. versions and that loads must be worked up again. (Think ‘ALTERNATIVE’ not ‘SUBSTITUTE’!) IMR-4831 in particular is noticeably faster burning than either H. equivalent. Using QuickLOAD to get a feel for how just much difference is involved, I ran the pair through the ballistics program for .284 Win set up for F-Class with a long-throated chamber to suit the 180gn Berger VLD at 3.200” COAL. The IMR powder’s top load within allowable pressures was no less than 3.8gn BELOW that of the Hodgdon SC version, a lot even when working with charge weights above 50gn! H4831SC was also predicted to give 42 fps higher MV than the IMR top load. This relationship varies by powder grade and can work either way – it’s reversed for 4895 with the IMR version able to use a heavier charge in .308 Win, 1.4gn with the 155.5gn Berger BT according to QuickLOAD, producing higher MVs – 28 fps from a 30-inch barrel in this example. (That’s confirmed exactly by Hodgdon’s excellent online menu driven handloading data website, the IMR maximum charge 1.4gn higher than the H version for 24 fps extra velocity from a 24-inch barrel with the 155gn Sierra HPBT in a Winchester case with F210M primer.)

So far as the H4895, H4350, and H4831/4831SC quartet are concerned, there are other possible alternatives. IMR-3031 and 4064, Lovex SO62 (Accurate-4064), Commonside TR140, Viht N140/540, Ramshot TAC are generally usable in applications that suit H4895. IMR-3031 is a much underestimated grade, thought of as a fast-burner only useful in the little .30-30WCF and similar. It’s a great propellant for .308 Win amongst others and can produce excellent velocities with bullets up to 175gn weight usually matching those from H4895. It’s long-grained though, so users of mechanical powder measures are generally not fans and its density may limit usable maximum charges in some cartridges. Viht N150/550 and N160, Lovex SO70 (Accurate-4350), Ramshot Big Game and Hunter, Alliant Reloder 17 / Commonside Elcho 17 can likely stand in for H4350 applications. Viht N560 and N165, Re17 / Elcho 17, Ramshot Hunter / Magnum, Lovex SO71 (Accurate-3100) are possible stand-ins for H4831 and H4831SC. Hodgdon SUPERFORMANCE ball type powder is a specialist and allegedly very case size sensitive grade that is only meant to be used in those cartridges that Hodgdon provides data for. Nevertheless, it has a burning speed somewhere close to Viht N160 / IMR-4831, maybe even a little slower matching H4831, and initial reports from those who’ve tried it in .284 Win are encouraging. (I’ll try it myself in the cartridge alongside Viht N165, Elcho 17, Lovex SO71, and IMR-4831.)

Incidentally, if you’ve noticed a grade listed as IMR-4007 SSC, a single-base super shortcut type whose burning rate falls between 4320 and 4350 and think it might be useful, then there’s bad news. Hodgdon quietly withdrew it recently after only four or five years’ production. It didn’t catch on despite suiting a few popular cartridges perfectly, .22-250 Rem with 55s apparently. If you’ve been using it, this is your last chance to restock while there are still some bottles around in the UK.

Unique?

A big issue / problem is VarGet. It’s not for nothing that the Hodgdon Powder Co. sells more of this grade than any other in its H / IMR ranges, outsells any other rifle powder on the market, I wouldn’t be surprised to hear. It’s not only a good ballistic match to the case-capacity / bore ratio of most of the best selling cartridges seen on the ranges or hills and moors, but is a very flexible number so appeals to the multi-calibre shooter who wants to restrict powder purchases and holdings. Where it’s ideally suited to an application, it often produces a mix of speed, small velocity spreads and minimal group dispersion that is unmatched by any other readily available propellants. The 6mm BR and its improved versions, BRDX, Dasher etc with 90-108gn bullets, is one such; for many 6.5X47 Lapua users and 120-130gn bullets, that’s another. Not such an issue here in the UK, but in the USA where season to season and even daily temperatures vary dramatically, VarGet was the original temperature-tolerant ‘Extreme’ powder and achieved a near legendary status as a result.

I can just about live without VarGet arriving this year as I only use it in 6BR for 600 yard Bench Rest competition and can eke out my remaining small stock for the 2014/15 winter match series. If it’s still unavailable after that, I should manage to find something that’ll replace it. For others this is a near disaster requiring them to find alternatives and work up loads from scratch for maybe three or four different cartridges. Whilst VarGet covered the lot, their replacements might require two, or even three new powders. So, the clamour has already started on Internet forums with requests for help in sourcing the powder now changing to pleas for advice on replacements … and the shouts can only get louder as people use up existing stocks and the supply drought continues. Given VarGet’s near uniqueness for some applications, that gives us our first pointer as how to cope with shortages. If you load it in several cartridges, and still have a few tins in stock, I’d advise prioritising its use to those numbers that obtain maximum benefit. A good example would be those shooters who find it unbeatable in 6.5X47 Lapua, but also load it in .308 Win. The latter is such a tolerant design and suits so many different powders that will remain widely available, it’s much better to rework your loads now for that cartridge than stick with the Hodgdon grade hoping that some supplies will turn up before you run out. The same applies to .223 Rem with mid weight and heavy bullets.

So what VarGet alternatives do we have? The problem is that there isn’t anything that seems to be a really close match as there is with the 4895 / 4350 / 4831 trio. Alliant Reloder 15 is probably the closest in performance and applications. Czech Lovex SO65 is shown with an identical burning rate by its manufacturer, Explosia a.s., but that doesn’t make it a shoo-in as a guaranteed successful substitute. The first problem lies in the definition, or at any rate, display of comparative burning rates. Let’s look at a typical chart, the type that puts powders in side by side columns, not a long printed list, and see what’s shown as being the same as or close to VarGet …………

Well, what does it say? The first problem is that I’m looking at TWO such charts right now and they disagree! Chart 1 shows VarGet being identical to Viht N133 (!!?), Vectan SP7, Norma 202, and Ramshot TAC. Chart #2 from another large powder manufacturer shows Accurate-2520 (Lovex DO73.6), IMR-4895, and Vectan SP7 as VarGet equivalents. In this one, N133 is three steps faster burning, N202 and TAC two steps faster. A third I’ve now dug out shows VarGet, Lovex SO65, IMR-4320, and (again) Vectan SP7 on the same horizontal level, this one putting IMR-4895 a couple of stages faster and N133 no less than five! Let’s throw another ingredient into the pot – I’ve got lots of SP7 (a French ball powder) and it simply does not work well in some applications where I know that VarGet would at the very least provide reasonable results. N133? As some charts suggest, this is a much faster burning grade, so seems an unlikely alternative.

QuickLOAD agrees:

43.0gn N133 = 59,903 Psi PMax; 2,873 fps MV; 102.4% fill-ratio; 100% charge burn

47.0gn H. VarGet = 59,854 psi PMax; 2,978 fps MV; 105.9% fill-ratio; 99.23% charge burn

(.308 Win, 155.5gn Berger at 2.900” COAL, 56.0gn water capacity fireformed case, 30-inch barrel.)

I’ve tried the allegedly equivalent SO65 too in .308 Win and 6.5X47 Lapua and fine propellant that it is, fills the case before achieving VarGet velocities. QuickLOAD theory matches my on-range findings as it takes a 50gn charge weight which represents an 11% case over-fill to achieve 59,947 psi PMax and 2,978 fps in the same .308 Win barrel-cartridge configuration in the computer model. The charge burn figure is predicted at a sub-optimal 97.79%. I’d never consider using a load combination with this degree of charge compression – strange effects can appear at these fill-ratios. (For those readers who don’t load for the .308, examples based on it are still useful as any pointers gained here apply to most cartridges with similar case capacity to bore ratios and whose case sizes limit the volume of the powder charge that can be used, this acting as a major constraint on powder choice. 6.5X47 Lapua is similar to .308W in this respect, but not as powder tolerant it seems.)

Misleading Metrics

Right! …… What’s going on here? First, nearly all manufacturers’ charge burn rate tables or listings have the word APPROXIMATE in the heading, and they mean exactly that. In other words, these tables are a VERY rough and ready guide to possible applications, nothing more. Far too many handloaders place complete credence on this single unreliable metric. Moreover, there are other equally relevant propellant characteristics that they ignore, a key pair being specific energy and specific density. H. VarGet has a very high specific energy for a single-base powder – 4,050 J/g (Joules energy per gram weight) compared to SO65’s 3,850 J/g. Our 47.0gn calculated maximum VarGet charge weight = 3.0455g = 12,334J energy and with 99.23% burned in the barrel that reduces a little to 12,239J. Meanwhile, 50.0gn SO65 = 3.2399g = 12,474J total charge energy potential, but with a predicted 97.79% burn factor that reduces to 12,198J taking us nearly to the VarGet figure, unsurprising as the pair produce similar velocities. So, we see that the apparently equivalent SO65 needs 3gn extra charge weight to produce a similar amount of heat energy to propel the bullet, but that in turn produces an excessively compressed load which may in itself affect both the REAL burning rate and pressures resulting in different and possibly undesirable behaviour. Although QuickLOAD has the same specific density for the pair in its propellants database, 1.600 g / CC, I also reckon that SO65 is also slightly bulkier than VarGet.

As a spin-off from doing these sums, one can also calculate a firearm’s thermodynamic efficiency with a load. If the QuickLOAD VarGet MV projection is accurate, the 155.5gn bullet’s 2,995 fps equates to 3,063 ft/lb ME, or 4,153J. That’s 33.9% efficiency, nearly two thirds of the powder charge’s energy wasted in heat, noise and recoil.

Incidentally, what does Lovex say in its loading data? Its nearest equivalent to my QuickLOAD modelled combination is a 150gn SPCE (soft-point cutting edge) bullet in an S&B case and with the S&B LR primer at 2.68” COAL. Max charge weight is 46.3gn (compressed) for 2,624 fps (23.6” barrel) at 46,400 psi (nearly 14,000 psi below the CIP allowed MAP). In fact, it takes the 200gn Norma Oryx bullet to see SO65 manage to get close to the .308W’s CIP PMax of 60,191 psi in Lovex’s own data, and every load combination with this powder is shown as compressed, maximum charge weights for lighter bullets dictated by what can go into the case not the pressures produced.

Newcomers

As it happens, I’m currently undertaking some range testing for two new (to the UK) high-energy European manufactured powders, one pretty fast burning but apparently able to be used in lieu of H4895 in .308 Win with 155gn bullets. Even though charge weights are significantly reduced, it’ll match H4895 velocities. The other has a similar burning rate to Alliant Reloder 15 and works very well in .308 Win and 6.5X47L with the same levels of charge weights as H. VarGet producing slightly higher MVs on a like for like basis. It’s not certain when they’ll go on sale, or even whether they’ll do so, and there are as yet only limited ballistics lab tested pressure and loads data available. Nobody that I know of has tried either grade in warm conditions either. So I won’t say any more other than ‘let’s cross our collective fingers’ as they may be an answer to the proverbial maiden’s prayer.

Options

So that leaves the tricky issue of what might provide a suitable alternative to VarGet until something akin to ‘my’ new powder appears or supplies of the original Aussie belter resume. I’ve already mentioned VarGet’s high specific energy (SE) rating, and that’s our first problem – IMR-4895 aside, hardly any alternative and likely to be available single-base powder come close to it and H4895 in this respect. Viht N140 is rated at 3,720 J/g, so needs a charge weight of 3.29g (50.8gn) to match that of the VarGet load in the 155.5gn Berger .308W example. Anybody with experience of handloading .308 Win with this powder knows that this represents a substantial, almost certainly dangerous overcharge, assuming you could get that amount of N140 in the case to start with – QuickLOAD says it produces a 113% fill-ratio and nearly 82,000 psi pressure.

N150 has a slightly higher energy value of 3,780 J/g, the Lovex extruded powders (SO62/65) a bit more again at 3,850 J/g. Lovex SO62 looks promising with QuickLOAD predicting similar performance to VarGet with a marginally lighter charge of 46.8gn needed to get the 155.5 Berger to 2,987 fps from a 30-inch barrel whose chamber is throated to accept a 2.900” COAL with this bullet. PMax is predicted right on 60,000 psi and charge burn at 99.98%, the fill-ratio slightly lower than VarGet’s too at 104.9%. Since SO62 is what used to be sold as Accurate-4064, a clone of the venerable IMR powder of the same name, the latter should work equally well in this application. Not that we need to work backwards from the Lovex propellant, as Sierra lists the IMR version with every bullet weight used in this cartridge in its manual. Hundreds of thousands of 7.62mm/168gn SMK IMR-4064 handloads were used up in US Service Rifle in its M1A / M14 rifle days, and it’s used in the current US M118LR 7.62mm sniper round with a 175gn Sierra OTM. It is a rather long-grained powder though, so charge weights may again be limited by case capacity in smaller cartridges like 6.5X47L and .308 Win. The Lovex (SO62) equivalent is shorter-cut and is a better match to the .308W/155 combination.

We should get IMR powders this year, so that hopefully provides IMR-4895 and 4064 options, also slightly slower burning short-cut 4320. In .308W at any rate, IMR-4895 will match H4895 MVs with 155s and better those of VarGet. Those who’ve tried it in F/TR rifles report good results. IMR-4320 will provide similar performance to VarGet, ballistically at any rate. I’ve not had outstanding results myself with this powder on the few occasions I’ve tried it in the .308 Win previously, but I’ve seen it recommended by many American authorities including for match use in the .30-06 with 168-190gn bullets. With 3,890 J/g energy and a burning rate that’s usually shown as comparable to Reloder 15 and Viht N140 (slightly slower than VarGet), a slightly compressed load will match VarGet’s pressures and velocities closely in .308 Win – on paper / QuickLOAD at any rate. (See Table 1 for QuickLOAD projections.)

High-Energy

Alliant Re15 is a ‘high-energy’ propellant, one with a degree of nitroglycerine infused into the already formed nitrocellulose kernels during manufacture. QuickLOAD promises good results and excellent MVs in .308W/155 and some F/TR shooters are using this propellant this year as it’s still available if you hunt around. It’s also suited to heavier bullets in this cartridge, near ideal for 175/185gn models, and has achieved excellent results for some in the 6.5X47L. ‘High-energy’ or not, its specific energy level is slightly lower than some of those quoted for single-base (NC only) IMR and Hodgdon numbers – on paper at any rate. Alliant’s Bofors manufactured propellants share a nominal 3,990 J/g SE so are slightly ‘cooler’ than H/IMR-4895 and VarGet. Many American competitors won’t use Re15 though, claiming it’s too temperature sensitive. This, as always, is less of an issue in the British Isles, but should still be considered when working a load up in under 10-deg C on a spring day on Diggle to be used at Bisley in July and August – retest the load in warmer conditions rather than discover you have a problem after the first few shots in an important match. High-energy extruded and double-base ball powders tend to be more sensitive than straight single-base types, and much more so than the Australian developed Hodgdon ‘Extreme’ grades. (Western Powders claims Ramshot TAC is very temperature stable though.)

Swiss Nitro-Chemie H-E types are nominally declared as ‘around 4,000 J/g’, so are similar to the Alliant products in this respect. Viht’s N500 series numbers are rated at 4,100, (N530 and N540), 4,050 (N550), and 4,020 J/g (N560), so one can see why some .308 Win F/TR shooters achieved very high 155gn bullet MVs with N540 in the discipline’s early days. Actually, QuickLOAD calculates that this powder produces similar velocities to VarGet and lower values than the 4895s if you remain within the cartridge’s 60,191 psi SAAMI PMax, 47.9gn giving our 155.5gn Berger 2,982 fps at just over 60,000 psi. More energy content … 100% charge burn too – no, I don’t understand this result either, but there will be a reason somewhere. So …. anyway, this likely explains why early F/TR users soon ran their barrels into the ground with 3,100 fps 155gn MVs and N540 as some very high pressures are predicted as being needed to achieve these speeds.

Round Objects

Of the possibly useful double-base ball types, we have a pair of very fine-grain Belgian ball numbers from Henry Krank: Ramshot TAC and Wild Boar shown as being very close on the company’s burning rate chart, ‘Wild Boar’ the slower version. Depending on the chart, they’re shown with TAC on the same line as VarGet and Wild Boar the next slowest, or alongside H4895 / IMR-4064, that is marginally faster burning than VarGet – in any event in the right area. Then there is Czech Lovex DO73.6 which used to be sold here as Accurate Arms-2520, another small grain ball type with a very similar burning rate as is the aforementioned French Vectan SP7. We finally have the long established US manufactured ball numbers – Winchester 748, H. BL-C(2), and H380 plus two recently introduced Hodgdon examples in this burning rate category: CFE223 and LEVERevolution. Both newcomers are listed by Hodgdon as slightly slower burning than VarGet and BL-C(2), and another chart I have shows CFE on the same level as Viht N135, LEVERevolution alongside N140 – ie bracketing VarGet. Alliant Powder has introduced some new ball MR (Medium Rifle) grades in the US, 2000-MR getting some rave reviews amongst club F/TR shooters, but I’ve not heard of any being imported into the UK. Although true double-base types (nitroglycerine as part of the primary mix alongside nitrocellulose), the ball powders don’t necessarily contain staggeringly high energy levels. Lovex Do73.6 has 3,700 J/g for instance with Vectan SP7 a bit higher on 3,765. Ramshot TAC and H. BL-C(2) are 3,950 and 3,990 respectively, so are getting ‘warm’. Ramshot Wild Boar is a Europe only powder and I can’t find its specific energy, but I’d expect it to be close to TAC.

With listed burning rates only a step or two slower than VarGet’s, good bulk density to allow near perfect full-case fill ratios, and their specific energy ratings, BL-C(2) and H380 look to be good VarGet alternatives on paper in both .308 Win and 6.5X47 Lapua. Returning to our hypothetical .308W F/TR 155.5gn subject, QuickLOAD shows 49.2gn BL-C(2) with a 98.2% fill-ratio producing an excellent 3,053 fps MV at just under 60,000 psi. Charge burn is good too at 99.7%. It doesn’t seem to work out so well in practice unfortunately, not for long-range precision shooters using this cartridge, anyway – I know several who’ve tried it and none stuck with it. And that’s an issue in itself, as competitive shooters with top grade hardware expect a huge amount from their ammunition nowadays. Many deerstalkers use such ammunition combinations (with appropriate expanding projectiles replacing the HPBT match types) with excellent results, not needing such a high degree of precision or shot to shot consistency over long strings.

Range Tested

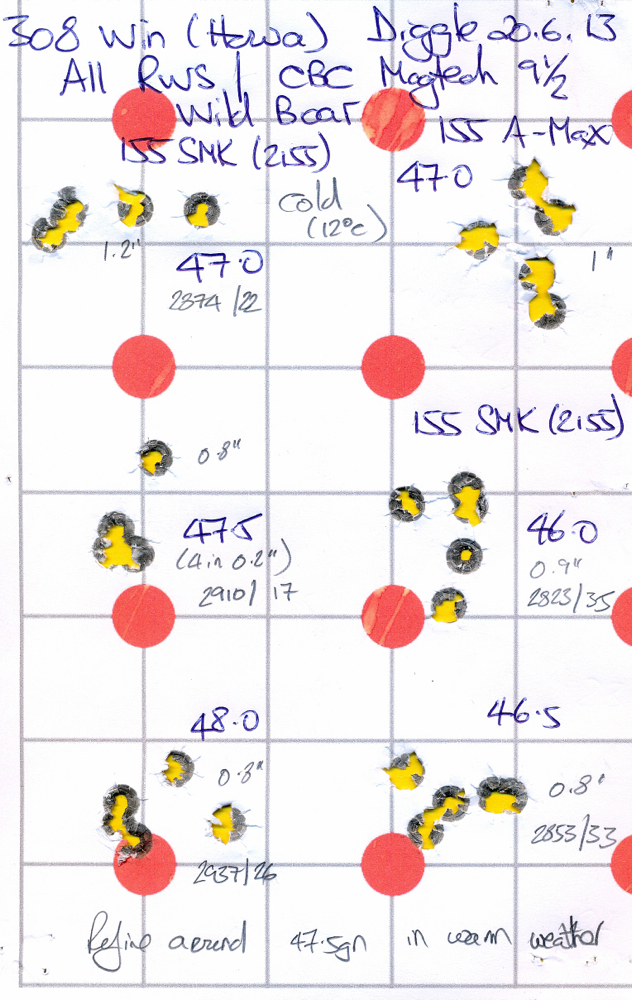

While Table 1 shows what QuickLOAD predicts, have I actually tried any H4895 / VarGet alternatives? Actually yes, but this wasn’t done with powder shortages in mind. Lovex SO62 and SO65, Ramshot TAC and Wild Boar loads were tried last year in .308 Win and one or two .223 Rem heavy bullet combinations, the former in the Howa 1500 Varminter I’ve been working on as a possible ‘affordable clubman’s F/TR rifle’. While its MVs are limited by a 22-inch barrel, some impressive results were recorded especially with the Ramshot pair getting 155gn bullets up to 2,900 fps, over from one combination. I’ll try these again and maybe one or two more in my 32-inch barrel F/TR rifle and report in due course.

Table 1

Possible VarGet substitutes in .308 Winchester: QuickLOAD Modelling

| Powder | Energy J/g | Charge (gn) | MV (fps) | PMax (psi) | Fill Ratio (%) | Burn % |

| H. Varget | 4,050 | 46.9 | 2,977 | 59,940 | 106 | 99.2 |

| IMR-3031 | 3,880 | 44.5 | 3,016 | 59,784 | 104 | 100 |

| IMR-4064 | 3,880 | 46.2 | 2,971 | 60,089 | 107 | 99.4 |

| IMR-4895 | 4,080 | 47.1 | 3,040 | 59,650 | 103 | 99.8 |

| IMR-4320 | 3,890 | 47.5 | 3,002 | 59,796 | 106 | 99.5 |

| Alliant Re15 (h/e) | 3,990 | 47.5 | 3,028 | 59,889 | 104 | 99.4 |

| Viht N140 | 3,720 | 46.3 | 2,946 | 60,136 | 103 | 100 |

| Viht N540 (h/e) | 4,100 | 47.8 | 2,981 | 60,151 | 103 | 100 |

| Lovex SO62(formerly Acc-4064) | 3,850 | 46.7 | 2,986 | 60,081 | 105 | 100 |

| Lovex SO65 | 3,850 | 48.3 | 2,884 | 53,711 | 108 | 96.8 |

| Ball Powders | ||||||

| Lovex DO73.6 Formerly Acc-2520 | 3,700 | 47.6 | 3,003 | 60,000 | 101 | 100 |

| H. BL-C(2) | 3,990 | 49.1 | 3,034 | 59,942 | 98 | 100 |

| H380 | 3,970 | 49.1 | 3,010 | 59,985 | 105 | 98.5 |

| Ramshot TAC | 3,950 | 46.4 | 2,993 | 60,061 | 95 | 100 |

| Winchester 748 | 3,840 | 47.2 | 3,029 | 60,109 | 96 | 100 |

| Vectan SP7 | 3,765 | 48.5 | 2,969 | 59,705 | 99 | 98.3 |

Notes

Calculations are for a 56.0gn water capacity case (Lapua in ‘minimum SAAMI’ chamber); 155.5gn Berger BT Fullbore bullet; 30-inch barrel, chamber throated to allow COAL of 2.900” with bullet just off the lands.

h/e = high energy (powders kernels infused with nitroglycerine)

PMax = peak chamber pressure calculated (SAAMI Max Average Pressure for .308 Win = 60,191 psi)

Fill ratio: 100% = full case with that bullet and COAL. >100% = compressed (108% highest level selected)

Burn% = % of the powder charge calculated to burn within the barrel.

WARNING!

The above data are entirely modelled using the QuickLOAD PC internal ballistics program, and are not pressure barrel tested. Actual results will vary depending on case capacity and barrel / chamber characteristics. The HIGHEST POSSIBLE CHARGE WEIGHT WITHIN THE SAAMI ALLOWED M.A.P. PRESSURE VALUES HAS BEEN USED. These data are for illustration only and must NOT be used without checking against other sources, WORKING CHARGES UP FROM AT LEAST 10% LOWER CHARGE WEIGHTS, ALSO CHECKING FOR OVER-PRESSURE WARNING SIGNS.