MasterPiece Arms are now just one of a dozen or more companies offering drop-in aluminium CNC’d stocks. Traditionally of course, wood was the only choice for a rifle stock, until fibreglass, wood laminate, polymer and even carbon-fibre came along.

Background – Aluminium Stocks

Back in 1989, the fullbore semi-auto rifle was effectively banned from UK civilian use. This plunged the Practical Rifle discipline into disarray as we scrabbled to find a bolt-action rifle with a detachable mag to continue with our sport.

The Accuracy International could have been the perfect solution – apart from the fact that it was prohibitively expensive and not available to civilian shooters! However a friend in Police Firearms had one and was happy to reveal the ‘bones’ of this now legendary sniper’s rifle. The early ones had a one piece lump of square-section aluminium bar running from butt to fore-end. There was a cut-out for the mag-well – which was welded on – and the barreled-action simply bolted in place. Moulded plastic sides completed the job – how simple – how ingenious! (Later models, employed a welded-up three-section chassis arrangement, which required ‘bedding’ of the action).

Inspired by the simplicity of the AI design, I built my own aluminium chassis – but not for Practical Rifle – Long-range Benchrest was now my obsession. I didn’t have a milling machine so the design was to be simple – inspired by the AI – a 40 inch length of square-section bar with a plastic butt and bag-rider and three-inch ‘accuracy asset’ on the fore-end. It worked and, on a good day, would shoot half MOA groups at 1000 yards.

Other manufacturers also started to exploit the use of aluminium – Sako for example upgraded their wood stocked TRG21 with the TRG 22/42 range – which used a simple extruded length of aluminium section, plastic fore-end and butt-stock but, it was only when CNC machinery became widely available that the creativity really took off.

The last time I visited the fabulous German IWA Shooting Show (way back in 2019…….) I was blown away by the number of CNC’d chassis systems now available. But, there are chassis and chassis…….. Unfortunately, many manufacturers don’t thoroughly understand the market and want to offer a chassis with as many applications as possible – to appeal to the widest market.

Naturally, this results in compromises – some are too short (for a long-barrelled F Class rig), or too heavy (to meet weight limits) or won’t work with a front rest (Benchrest, F Class) and then of course there is the suitability for different actions. Whereas fibreglass or wood-laminate stocks can be offered as a ‘blank’ then inletted and bedded to accept almost any action, it’s a different story with aluminium and many – like AI’s own commercially available chassis – only cater for actions with the Remington 700 footprint.

Although it’s undoubtedly convenient to have a ‘drop-in’ – needing no bedding or machining – it’s not necessarily the best arrangement – if you are looking for a super-accurate rifle. Two machined cylindrical surfaces may appear to offer the perfect marriage (bed) but rarely do.

So why are CNC machined aluminium stocks so popular? Well, firstly the ‘drop in’ appeal cuts out the bedding process – a specialised (and expensive) procedure best left to the professional gunsmith. Secondly, they are available ‘off the shelf’ – no waiting around for inletting, paint-finishing etc. Thirdly, they are robust, weatherproof and most importantly – they work! Taking into account the money saved on bedding and finishing, they are also competitively priced.

One of the other reasons for the increasing popularity of CNC’d stocks is the relatively new discipline of Precision Rifle. PRS has swept America and inevitably found its way to the UK and most of Europe in recent years. Precision Rifle demands a high level of accuracy from a magazine-fed rifle, which must be light enough to be shot in any position including un-supported. Pic rails for scope-mounting, sling-swivels, M-loks and bi-pod mounts are a ‘must’ and adjustable butt and a movable cheek-piece are desirable features.

The MasterPiece Arms Stock Systems

So, with that introduction out of the way, lets have a look at what Masterpiece have on offer. In addition to stocks for bolt-action rifles, they have many other offerings – including complete rifle builds, pistols, semi-auto stuff etc. but we are looking at their stocks for bolt-guns.

I confess, MasterPiece Arms is not as well known to me as say KRG or MDT but, a visit to their website www.masterpiecearms.com will convince you that they are a major player in the Precision Rifle game, with a string of match results literally as long as your arm dating back to 2016.

MasterPiece offer half a dozen chassis variants but, the two most likely to appeal to UK shooters, are the basic MPA BA Competition Chassis and the Matrix – which is an upgraded version with additional features.

The BA Competition Chassis

This is the base model chassis and is the one used by many successful American PRS shooters since its introduction in 2016. It’s designed to be a drop-in for Remington 700 footprint actions as well as Tikka, Howa, Savage and a variety of other inlets including Bat Machine HR & VR, Bergara, Curtis Axiom, Curtis Vector, Curtis Helix, Defiance Deviant, Defiance Rebel, Defiance Elite, Stiller Tac30 and Tac300, Bighorn TL2, Bighorn TL3, Lonepeak Arms, Kelbly Atlas Tactical, GA Precision Templar V2, GA Precision Tempest, Impact 737R, Surgeon SA & LA (Except Surgeon XL) and Ultimatum Deadline.

Here’s the spec. and features:

- Machined from 6061 aluminum

- V-Bedding system

- Skeletonised butt-stock with adjustable cheek-riser

- Additional vertical grip

- Front night-vision bridge

- Multiple QD sling-swivel locations

- User located side rails (option)

- Adjustable length of pull 13.50-14.75″

- Recoil pad adjustable for height and cant

- Built-in bubble level

- Machined thumb notch

- Rear Bag Rider

- V4 Spigot Mount

- 2 Round Ammo Holder

- RAT Rail (Rapid Adjustment Technology) AKA 1.5″ Dovetail or Arca Swiss Rail

- Weight 5 lbs

The V-Bedding system is configured to allow proper bedding of the action if desired.

The Matrix Chassis

The Matrix chassis is an enhanced version of the base model Competition chassis. It offers a multitude of configurations to help the shooter to get a perfect stock fit.

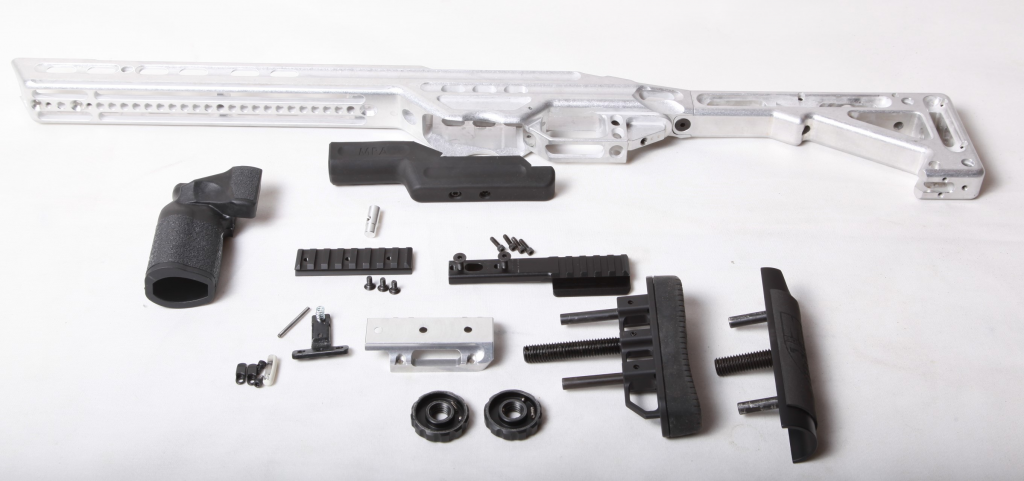

Included in the box are some interesting bits n bobs. Although at first glance, the Matrix appears to be a ‘thumb-hole’ stock – it isn’t – in the conventionally accepted sense.

Rather than inserting the thumb through the ‘thumb-hole’ and gripping the stock, we have a small plastic ‘thumb-rest’ which screws to the side of the stock just above the hand-grip, providing a perfect resting place for your thumb. I like this method of holding a (rested) rifle and is exactly what I would do with a benchgun or F Class rifle – no need to take a vice-like hold of the pistol-grip. I like it – so much that I’m going to try and rig a thumb-rest on my own MDT tactical stock.

However, the large hole in the stock does have a purpose – when you’ve shot your string off bi-pod, barricade or WHY and need to move quickly with the gun and all your gear – you can take a firm grab around pistol-grip with one hand and grab your gear with the other.

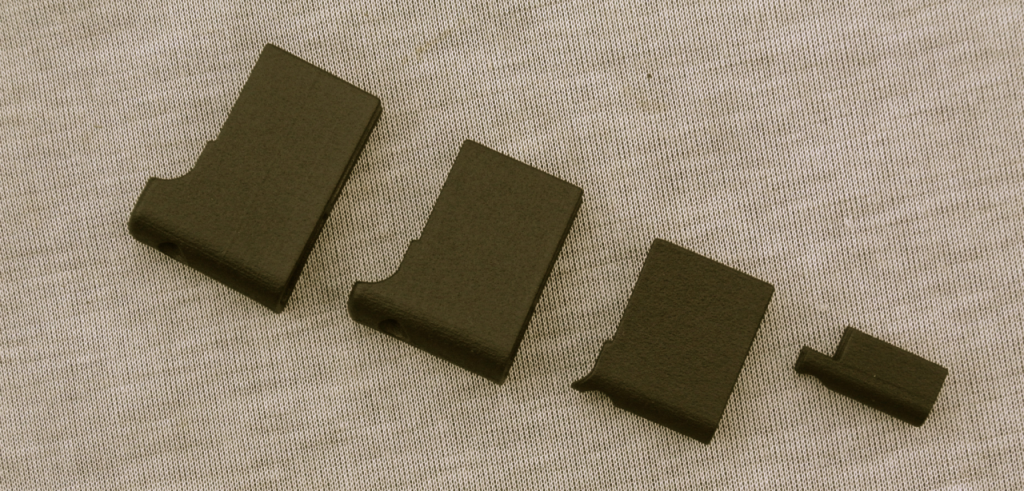

Additionally, the location of the shooters hand provides even more variation in how the shooter can set up this chassis. Two pistol-grips come with the rifle – one is thicker than the other (on the front face) – if your fingers are short, use the thick grip and it will take your index finger closer to the trigger. Further grip options are available.

I must admit that ‘stock fit’ has never been an obsession – I shoot benchrest one week, (minimum stock contact preferred, no adjustment cheek-piece or butt) maybe tactical the next (cheek weld etc) but because I’m sometimes wearing thick winter clothes or just a light top, I ‘make do’ and try to adjust myself to the stock. However, this isn’t the MPA way and MPA do their best to allow you to customise the Matrix to your exact requirements. It’s got me thinking…..

The third device – the trigger-finger guide – is another interesting addition. This plastic moulding can be fitted to the rear of the trigger-guard and it ensures your trigger-finger tip properly engages with the trigger. Yes – we all know how to do this – and, with disciplines like F Class, you have all the time in the world to get your index finger-pad correctly positioned after carefully closing the bolt but, in the heat of PR competition, it’s so easy to rack the bolt and just snatch the trigger. The Matrix trigger finger support – when combined with the correct thickness of pistol-grip and thumb-rest – gets the pad of your index finger in exactly the right place – every time.

You don’t have to fit it but it’s there if you want to give it a try. I like the idea, it works well with the thumb-rest and I just wish I could get on range and try it live firing……….

Of course, the (rubber-faced) cheek-piece is adjustable, as is the rubber butt-pad – for length of pull plus raised, lowered and canted. If I could make one modification – a quickly detachable cheek-riser – to facilitate cleaning.

There’s yet another item – an extended pic rail. Effectively making the stock a couple of inches longer – for better bi-pod stability when you’re taking that extreme range shot. Simple but a good idea. Easily fitted and removed with an Allen key.

Clearly, MPA have PR shooters on their design team and have put a lot of thought into their products. These are not just CNC machined stocks – these are stocks designed for a specific purpose – to enhance your PR/tactical shooting and, if this is your discipline it might be worth giving the MPA range a second look. However, I don’t see why you couldn’t build an F Class gun on an MPA stock – there are plenty of metal stocks already on the circuit.

Hopefully, when we get back on range we can put some rounds through the Matrix and check out how these add-ons actually work in the field.

Here are the additional features on the Matrix:

- 6 grip options (one additional grip included)

- 3 thumb-rest options

- 4 trigger-finger support options

- M-Lok slots along the sides of the chassis fore-end

- Barricade stop holes on the bottom of the fore-end

- Additional 2 inches of length to the fore-end (from the BA Chassis)

- Standard or enhanced night vision bridge

All of the chassis systems are designed to take the AICS type magazines and come with a great unique feature, which offers the shooter or gunsmith to finely adjust the mag-release catch so that it perfectly holds the magazine at the correct height. Those who’ve fiddled about with magazine-catch lengths to perfect feeding will appreciate this feature.

GS Precision are now stocking the Base model and the Matrix. You will see from the MPA website that the stocks are available in a choice of 8 Cerakote colours but, rather than attempting to stock a range of colours (but never having the one you want) GS Precision are wisely buying the stocks ‘in the white’ and Cerakoting in house to your colour choice – which offers many more colour options and is included in the price. How sensible.

GS Precision will sell you a stock or build you a complete rifle – including action bedding if you wish. The one I’m reviewing (sadly I can’t shoot it at the moment) is the Matrix, fitted with a Canadian Ultimatum Deadline action (GSP are the UK importers) and chambered in 6.5 Creedmoor.

Contact GS Precision at http://gsprecision.info and click on http://www.targetshooter.co.uk/?s=ultimatum to read our review on the Deadline action.