NEW (again) TO BRITISH SHOOTERS: RAMSHOT POWDERS

Many years back, a high-profile, ambitious British retailer announced he’d import and supply almost any handloading powder that was available in Europe and the US. As well as taking on Edgar Brothers with Hodgdon and Alliant, Hannam’s with Vihtavuori, he’d supply Accurate Arms, IMR (this was before Edgar Bros. began importing the marque), Winchester, Ramshot …………. and, probably a few more that we’d barely heard of.

Ramshot powders were then quite unknown to British shooters and, I don’t think this initiative changed that situation overmuch. In any event, he and his business ceased trading a year or two later but not before I bought a tin of every one of its products. (Only he failed to include one I’d ordered and paid for – and spent months ‘forgetting’ to either produce it or refund my twenty odd quid – I later wondered if others suffered such customer service hastening his exit.)

So, when Henry Krank recently announced it was importing, distributing and retailing all bar two or three lines, these propellants weren’t entirely new to me and, my earlier acquaintance had impressed me enough to welcome them back. Coinciding with powder shortages that have spread from the US to Europe, this is a happy time for their introduction, especially as the supply chain is direct from the factory, secure and doesn’t involve competing against the US retail giants.

Belgian

Belgium isn’t known for making much that we need – fine chocolate aside but, that’s where all bar a couple of the missing grades originate. That’s PB Clermont’s factory to be precise, (the name is short for Poudrerie Belge de Clermont) located just down the road from the great armaments manufacturing centres of Herstal and Liege and who’ve been in business since 1850.

The missing US pair are: ‘Silhouette’ (pistol), ‘Competition’ (12b shotgun / light revolver target). Sadly, it also appears we’ve lost out on ‘Hunter’ rifle powder – see below. Those powders we do see – five rifle and three pistol/revolver grades – are made in a facility that was converted to producing ‘spherical form’ powders around 50 years ago, the then independent PB Clermont purchasing a manufacturing licence from the Olin Corporation in the USA who’d patented the production process.

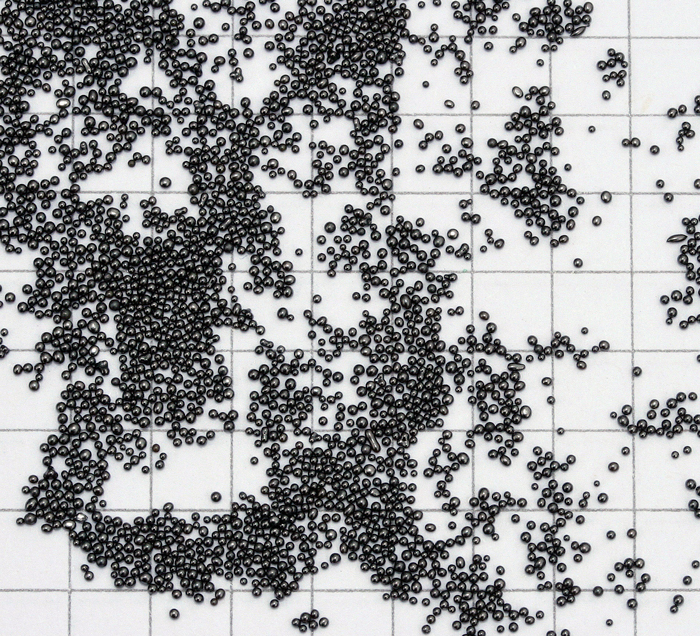

The plant has been regularly upgraded since and features a strong R&D presence, the company specialising in state of the art versions of these powders. PB propellants are used in many makes of commercial pistol, rifle and shotgun cartridges, not to mention specialist propellants for industrial applications. The key military applications activity encompasses products for smallarms and cannon cartridges up to 25mm calibre as well as secondary charges used in mortar bombs. The last named customer type is not unexpected as many, in fact most, ordnance procurement organisations prefer ‘spheroidal’ rifle powders over the extruded (tubular stick) types that precision minded civilian shooters naturally gravitate to. ‘Spheroidal’ / ‘spherical’? That’s little round balls to you or me but one has to be wary of saying ‘ball powder’ in print as the Olin Corporation trademarked that name years ago and the sole right to use it still resides with its successors.

As with all such (‘ball’) types, all Ramshot grades are ‘double-base’ (D-B), that is a percentage (8-42% here depending on type, pistol grades highest) of the ingredient mix is the high-explosive nitroglycerine (NG), chemically combined with less energetic nitrocellulose (NC) during the production process. Single-base (S-B) powders use NC alone. (The rule of thumb is that if it’s ‘ball’, it’s D-B as adding NG is an integral part of the production process for this type. If it’s extruded, it can be either, D-B examples normally starting out single-based and infused with NG at a late stage in their manufacture.)

Adding or incorporating the nitroglycerine component increases the propellant’s energy per grain weight. It also increases the bulk density compared to that of an S-B propellant with identical kernel dimensions, so you get a slightly heavier charge into a space-constrained case before producing a compressed load. D-B propellants burn a bit hotter and that can mean cleaner. Nevertheless, traditionally ‘ball powders’ were dirty and that was because they had a cocktail of non-inflammable treatments and stabilisers added to control burning rates, reduce muzzle flash, flame temperatures and do various other jobs – as do stick types but this form used to need more of them including 2- 3% of the total weight being calcium carbonate, common or garden chalk to you and me, which is used in their manufacturing process. Some of these elements remain behind in the barrel as fouling. Also traditionally, D-B types – whether extruded or ‘ball’ – were accused of wearing barrels out faster through accelerated throat erosion from their higher flame temperatures.

Breaking Moulds

On the face of it, both traits rest uneasily with government small-arms ammunition procurement requirements: badly fouled automatic weapons are unreliable; increased wear also reduces reliability as well as incurring more frequent weapon refurbishment bills. Another often quoted downside is that D-B propellants, whether spherical or extruded, are more temperature sensitive than S-B competitors and again this seems inconsistent with military requirements that expect weapons and ammunition to perform reliably in any region or season.

With these alleged downsides you have to wonder why many governments specify this formulation for their rifle cartridges – as the US has done exclusively since the introduction of the M80 7.62X51mm 150gn ball cartridge back around 1956. It still employs that procurement policy with both 7.62 and 5.56mm ammunition production, a few special-purpose numbers such as the M118LR 7.62mm sniper round aside. (It currently uses Alliant Re15.) So, either Uncle Sam and his relatives in other countries are plain stupid, or governments and military ordnance officers know something we don’t.

Here are some factors that influence these purchase decisions. First, spherical powders usually have lower production costs than their extruded equivalents, this feeding through to significant ammunition cost savings when we get up to the huge quantities that governments consume. D-B powders, particularly the spherical type, are stable under storage in all sorts of non-optimal conditions with a long shelf-life whether stored loose in bulk or loaded in ammunition.

They meter well in mechanical powder-measures and, ammunition factories use the same system as Lee does in its sliding plate Auto-Disk measure but on an industrial scale with multi-cavity metering plates. That produces more consistent charge weights than with stick types, so more consistent MVs, and of course gas-port pressures needed for reliable operation of military automatic weapons.

And, when we say ball powders are dirty and being double-base wear barrels out quickly, that might have once been true and there is a saying on the lines of ‘Give a dog a bad name ….’ The ball form has been around for a long time, since the late 1930s and extruded D-B types even longer, Alfred Nobel introducing ‘Ballistite’, the first ever D-B propellant way back in 1887.

The British government scientists Sir Frederick Abel and Sir James Dewar produced the similarly manufactured and formulated ‘Cordite’ two years later. So similar, Nobel took them to court claiming patent infringement but lost his case thanks to a poorly chosen six-word phrase in his patent that gave HMG a let-out!

Early ‘Cordite’ 303-inch ball ammo loaded with a propellant employing a 58% NG, 37% NC, and 5% petroleum jelly cocktail would ruin a contemporary Long Lee’s barrel in about 1000 rounds. Early US military smokeless powders were also high-NG content D-B types producing the same disastrous effect on barrel life – I’ve seen quotes as low as 600 rounds taking us into maximum load 7mm WSM territory in today’s F-Class!

Whilst powder manufacturers have long since ameliorated, now completely overcome this unfortunate trait in early versions of the genre, the reputation lives on. (By World War 1, Cordite’s NG proportion had been nearly halved with a consequent improvement in barrel life, the main barrel-life determinants then switching to wear and tear caused by corrosive primer salts and the copious metallic fouling that cupro-nickel alloy bullet jackets produced prior to the interwar adoption of gilding metal.)

Much R&D has also been applied to losing the ‘dirty burning ball’ label and, PB Clermont SA’s long established facility, now part of the Eurenco propellants and explosives manufacturing combine is a leader in the field. Its versions of the tribe are claimed to be the cleanest burning ‘spherical’ products ever. 95% of the plant’s output is exported, that including Accurate Powder’s spherical grades as sold in the US. (But not ‘Accurate’ powders as imported by Westlander Ltd. and sold in the UK – they are Explosia ‘Lovex’ brand propellants from Semtin in the Czech Republic, the confusion arising from this company supplying the old Accurate Arms outfit for many years prior to its purchase by Ramshot distributors Western Powders Inc.)

Barrel life

So far as barrel-life with these powders is concerned, their manufacturers and proponents now argue that you actually get longer barrel life from ammunition loaded with it! This results from a great deal of R&D into additives which reduce flame temperatures alongside the fouling reductions.

There is another throat wear factor – the erosive effect of a mass of burning – and still to be burned – powder granules that are forced out of the case-mouth and into the throat/leade section of the chamber immediately behind the bullet as it starts to move. It’s argued that ‘sticks’ are more erosive than tiny smooth round balls. Apart from this being conjecture as nobody knows precisely what happens during the smallarms cartridge combustion process, I find it really hard to believe that one form or other of burning powder kernel inflicts a significantly lesser or greater degree of torture on barrel steel through the friction it generates compared to another. Anyway, here’s what Sierra Bullets says about the issue in its Ballistics section:

Some debate has ensued over the merits of ball powders vs. extruded tubular powders. Extensive testing at Lake City Ammunition Plant found ‘no significant difference in bore life, accuracy wise, when using either IMR propellants (extruded tubular) or spherical propellants (ball powder)’. While these comments were made specifically about the 30 caliber and 7.62mm NATO ammunition, the same situation will hold true for most other cartridges.

That research was likely undertaken some time ago but I’d be surprised if relative bore-wear performance between the two types has changed to any degree, although R&D and manufacturing process improvements have provided significant overall improvements for all propellant forms in recent years. What the military research does confirm is the commonsense view that both formulations provide similar barrel life providing the charge weights employed produce similar pressures and velocities. However, since many handloaders choose D-B powders, whether ‘ball’ or extruded, to increase performance, that changes the equation and if you do this, you will see a barrel life reduction.

Eightsome Reel

As noted, Henry Krank has eight grades in stock, selling them directly to handloaders and also wholesaling them to other retailers nationwide. There are three pistol grades – ZIP, a fast burner in the Red Dot, HP38 class that’s used for light target loads in 38 Special up to 44 Special/Magnum. It works very well in .45ACP and some other auto-pistol cartridges too, it’s said. True Blue has similar applications to Unique, although shown as faster burning – so mid or full pressure loads in 38 and 44 Special and 45 Colt plus mid-pressure loads in the Magnums with either lead of jacketed bullets. That leaves Enforcer with a burning rate close to Alliant 2400 and Hodgdon H110, a full-house performance inducer in the revolver magnums and usable in a few small rifle cartridges like 22 Hornet and 30 Carbine. I tried ZIP and True Blue when I bought my original Ramshot numbers and had good results in pistol-calibre lead bullet lever-gun loads in some limited testing.

Moving onto the rifle sextet – or, as it turns out, quintet – the fastest burner is X-Terminator, useful for the 17s, twenties up to and including the 204 Ruger case size, 222 Rem and 223 Rem with bullet weights up to 60gn. It has a similar burning speed to Viht N130, Alliant Re10x, Hodgdon Benchmark, IMR-3031 and will do the same job as them in a fair variety of smallish bottleneck cased cartridges – 6X45mm, 6.5mm Grendel, 6.8mm Remington SPC – and also the big-bore straight numbers like 444 Marlin and 45-70. It’s at its best in 223R with bullets in the 40-55gn weight range but loads are provided for heavier models. It could be used with lighter bullets in 308 Win as confirmed by running some combinations through QuickLOAD but fill-ratios dip to around the 90% level and the velocities achieved within maximum safe pressures are a little low. So Ramshot doesn’t provide data for that combination, concentrating instead on the not that much slower burning …..

TAC, whose burning rate matches that of the much-missed Alliant Re12 of days gone by. It falls between Hodgdon BL-C(2) and H4895, likewise Viht N133 and N135. This is a flexible number with a large range of uses in small to mid size cartridges and Henry Krank’s Ken Grey tells me it’s the company’s biggest seller. It’ll work in 223 Rem with the lighter bullets but really comes into its own with projectiles weighing 69gn or more where it gives better velocities than X-Terminator, although not that much more. TAC promises good results from 308 Win with a good size bullet-weight range, data provided for bullets up to 200gn. I had excellent results from TAC in a heavy-barrel 308W Ruger 77V with 155gn Sierra Palma MatchKings in my earlier try-out, so was keen to try it in my Howa 1500 ‘affordable F/TR rifle’ with its short 22-inch barrel. Running TAC + 155s through QuickLOAD suggested I should exceed 2,800 fps despite the barrel length. It’s still fast-burning enough to have uses in some big-bore straight-case rounds too.

Wild Boar is only available in Europe but, I’ve seen views on American forums that it’s the same thing as Accurate 2520 as sold in the USA. Western Powders’ load data and MVs for a sample of cartridges that I looked at give close but not identical, weights and values for the pair. (Note that’s ‘new Accurate-2520’ also made in Belgium, not the ‘old’ Czech Accurate Arms variety still sold here which is more accurately designated as Lovex DO-73.6.) Assuming that it is ‘new Accurate-2520’ in another guise or something very close, it’ll have a similar burn rate to Hodgdon Varget, IMR-4895, and Viht N135.

Ramshot produces copious loads data for ‘Wild Boar’ in a dedicated document, getting on for 40 cartridges from 17 Rem Fireball to 550 Magnum including four 20-calibres. There is a striking number of load combinations for 223 Rem and 308 Win alone – far more than in the main Ramshot handloading guide – covering every bullet weight available up to 90gn in the Mouse Gun number and 210gn in the thirty, and as is usually the case with Ramshot/‘new Accurate’ data, the former is provided in separate 223 Rem SAAMI (55,000 psi max) and European 5.56mm (62,350 psi max) tables.

In 5.56mm guise, Wild Boar’s maximum load under a 90gn Sierra MK promises 2,701 fps, and in 308 Win the 210gn bullet maximum load MV is listed as 2402 fps, both in 24-inch barrels and both at SAAMI/CIP COALs of 2.260in. and 2.810in. respectively – most impressive if they’re actually achievable in these circumstances. Actually, I simply don’t believe they are achievable and worry about the likely results of loading the pair at the short SAAMI standard COALs. Load the 90gn SMK into 223 Rem at this COAL and around two-thirds of an inch of bullet shank and base are located within the small case with a huge effect on the fill-ratio and peak chamber pressures, similar issues afflicting the 308 Win/210gn VLD combination at 2.810-inch COAL. In any event, Ramshot promises high MVs in many applications and, if the powder performs at all like Accurate-2520 (in either guise), it should deliver some of the best velocities going for suitable applications.

Slower

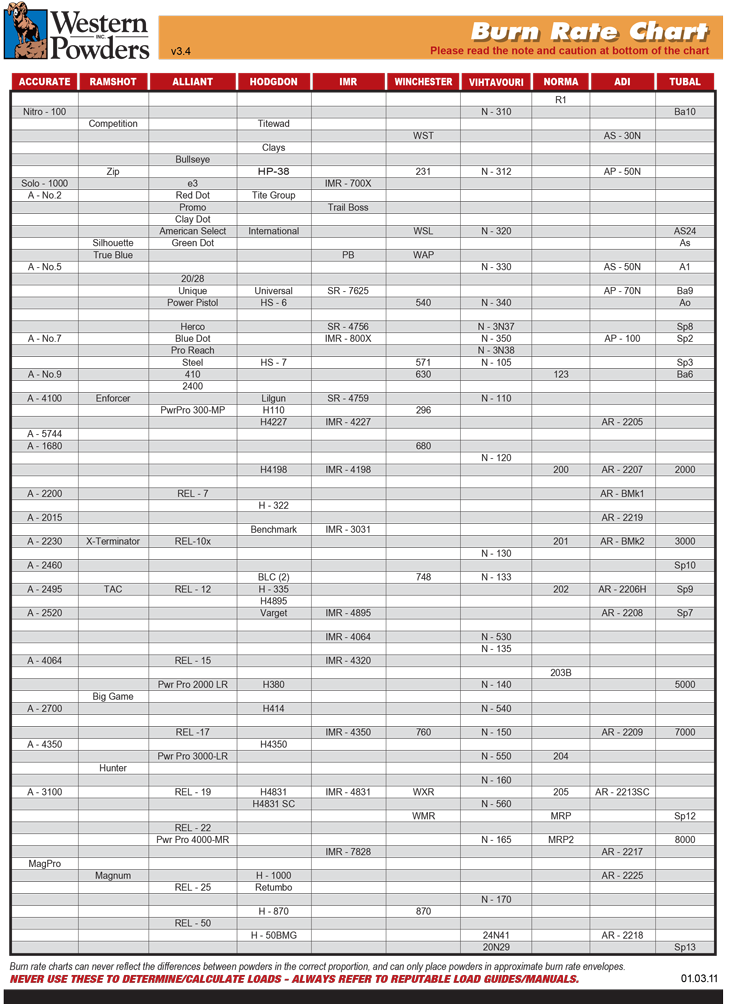

That takes us to the trio of slower burners, although we must note that equivalent burning rates for this type of D-B ‘spherical powder’ seem to consistently show a grade as being faster burning than the actual applications and recommended charge-weights would otherwise suggest. In any event, one must treat all burning rate comparisons with caution as they’re often seriously misleading.

Big Game is shown as equivalent or close to Viht N540 and Hodgdon H414/Winchester 760. Ramshot describes it as ‘the ultimate 30-06 powder’ filling the case, giving high velocities and very consistent pressures. The same situation allegedly applies to 22-250 Rem. where the load data shows a 55gn Ballistic Tip getting a shade under 3700 fps from a 24-inch barrel.

I worked loads up in 308 Win with the 180gn JLK long boat-tail VLD long-range bullet with excellent results and QuickLOAD suggests this is an excellent choice for ‘heavies’ in the cartridge, the load that gives a 100% case fill-ratio under a 210gn Berger VLD in a rifle throated to allow 3.00-inch COAL producing an estimated 2610 fps (30-inch barrel) at just under max SAAMI pressure with a 100% charge burn.

It’s a bit slower burning than Reloder 15, so I thought it might be a tad too ‘slow’ for 223 Rem even with the real heavies but it certainly comes into play for the bigger ‘sixes’ and smaller 6.5s like 260 Rem and 6.5mm Hornady Creedmoor. Generally though, these numbers see best results from lighter bullets with this powder or MVs are down if Big Game is used with the heavier projectiles as in 100-105s for 6mm and 140s for 6.5. These combinations are better suited to ….

Hunter, a powder in the H4350 class whose claimed burning speed lies between Viht N550 and N160. It’s suited to the 300 short magnums, 6.5X55mm, 270 Win, heavy bullets in 30-06, as well as 6XC, 243 Win, 6.5X47L, 6.5mm Creedmoor and similar. This is a propellant that I’d looked forward to trying but Henry Krank hadn’t managed to get any in – subsequently removing it from its shooting magazine advertisements. It turns out that it cannot be imported into the UK as it contains some mystery ‘illegal ingredient’, only nobody knows just what this is. Shame, as it looked ideal for a whole bunch of 6.5s that I plan to start work on from this autumn/winter. Given the way CE certification works, I suspect that ‘Hunter’ cannot be sold anywhere in Europe and is an export to the US only job.

Anyway, we do get the slowest burning grade, Magnum which was originally given the unfortunate name of ‘Big Boy’, a true magnum rifle powder whose place on the burning rate chart suggests it falls between those of Viht N165 and N170, matches Hodgdon H1000 and is rather faster burning than IMR-7828, so it’s one for 6.5-284 Norma, the 270 and 7mm magnums, 300 Win Mag, 338 Lapua Magnum but apparently still works well in 6.5X55mm with 130-142gn bullets giving higher claimed MVs than ‘Hunter’ even at its modest SAAMI pressures.

That suggests it might also be suited to 284 Winchester match loads – the ‘straight 284’ as the cartridge is often misleadingly called – with heavy bullets seated well out. It’s not listed for 300WSM and SAUM and the latter certainly looks short on capacity for this powder. However, QuickLOAD suggests it might work well in the slightly larger WSM case in a long-throated chamber, a lightly compressed charge producing an estimated 60,000 psi and almost 3000 fps for a 210gn VLD in a 30-inch tube.

Real Life

So far, we’ve only talked manufacturers’ data and QuickLOAD modelled estimates. You might have noticed I’ve not quoted any load combinations from bullet manufacturers’ handloading manuals, Speer, Sierra, Nosler et al. There is a reason for that – the new Berger Reloading Manual 1st edition aside which includes a modest number of Ramshot fuelled combinations, there simply aren’t any. Accurate and Ramshot seem to be invisible powders for the other bullet makers’ ballistic labs and data compilers!

Anyway, I’ve been able to get some testing in using 223 Rem, 308 Win and a single batch of 30-06 Springfield, variously with TAC, Wild Boar and Big Game. The trio burned exceptionally cleanly, leaving less muck in the barrel than extruded Hodgdon, Alliant and Vihtavuori powders. I’ve got to say I was astonished at this!

Another sign of good ignition and clean combustion is that case-shoulders have been left clean and necks usually only gained a moderate fouling wash. Even so, this becomes difficult to remove if it’s left untouched for any time, presumably having been burned on at high temperatures. Good old Brasso ‘Duraglit’ impregnated wadding metal polish is as good at removing this film as anything I’ve tried to date. Another recommended practice, which will often be impractical in range/competition conditions, is to spray fouled necks immediately after shooting with WD40 or better still ‘Ballistol’ oil, from an aerosol can, allow either product to soak in for a few minutes before wiping the softened goo off with paper towel.

What about temperature sensitivity? I can’t comment on that, most test firings held in the unseasonably chilly weather we suffered before the July heatwave started. Here’s what Keith Anderson of Western Powders’ ballistics lab said in a forum post last year:

“All of the powders sold under the Ramshot or Accurate brands meet or exceed the military specification [presumably NATO?, author] for hot and cold stability. As with anything, some powders are better than others. Single base powders such as Varget can be made to be more temperature stable than double based powders such as Accurate 2520 although there are trade offs to anything. While the nitroglycerin in a double based powder makes it less temperature stable it is the component that makes double based powders cleaner burning and allows them to attain higher velocities and their single based cousins.

In both the single base and double base lines of powders some powders have better temperature stability than others, Ramshot ‘TAC’ is one of the most temperature stable double based powders available. It is this very reason that so much of it is being used for military applications in both Iraq and Afghanistan. Even under extreme temperatures Ramshot ‘TAC’ will vary less than half what the military will allow.”

Metering

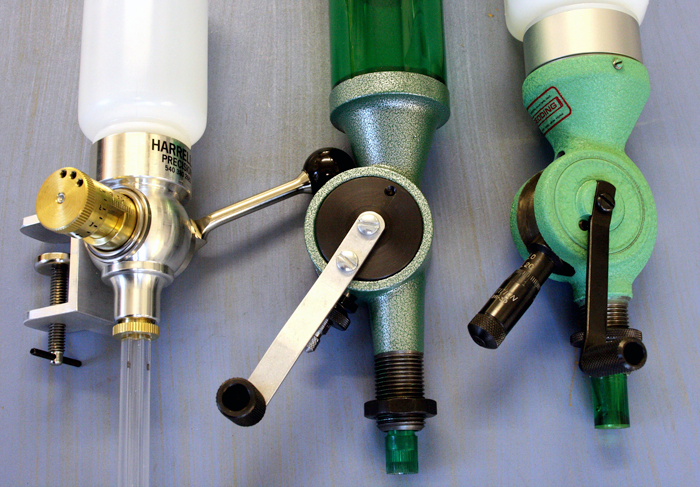

Many handloaders like ball powders for their suitability for use in traditional mechanical powder measures, producing easy flow through and consistent metering from such devices – no bridging/hanging-up in drop tubes and similar – and producing more consistent weights than with equivalent extruded (stick) powders.

I used my RCBS Charge Master combined electronic scales/dispenser to produce charges for my set of first trial loads but found it’s not that well suited to such a fine ball powder. It threw accurate and consistent charges OK – very consistent actually – but the powder flows too well for this device. By that I mean that if you knock the bench or the Charge Master at all, powder is dislodged from the mouth of its trickler tube. If this happens as you’re removing or replacing the scale pan, you’ll likely get an over-charge.

If the scale pan has been removed, the spillage goes onto the scales body and the bench-top. As these tiny balls bounce around everywhere, some inevitably end up inside the RCBS 1500 scales’ casing, moreover in places where errant powder granules can affect the whole combo’s operation and reliability. After that episode I returned to a conventional measure and found that all charges thrown were within a 0.3gn range, most in a much smaller one.

I’d have little concern over using charges ‘as thrown’ by a good conventional powder measure for short-range target shooting and most sporting rifle cartridges’ usage. As always though, check the measure’s settings carefully on your scales before using any charges and do a check-weigh every five or ten charges thrown to ensure that nothing changes during a session.

Some Results

That just leaves me to report on some of those few tests I’ve got using 223 Rem and 308 Win. Ramshot’s online data ‘booklets’ were downloaded from the company’s website as Adobe .pdf files (remember, ‘Wild Boar’ has its own comprehensive data-set). QuickLOAD was also employed with Accurate-2520 substituted for ‘Wild Boar’.

I loaded up a quartet of 55 to 69gn bulleted loads in 223 for a 26-inch barrel sporter/tactical rifle and some 80.5gn Berger BTs and 90gn VLDs for my long-throated F/TR rifle, these various combinations involving TAC, Wild Boar and Big Game as appropriate. 308 saw TAC and Wild Boar tried in a 22-inch barrel Howa 1500 Varmint with 155s and a 180gn JLK VLD plus Ramshot Big Game combination in a custom Savage F/TR rifle with a 10-inch longer tube up front.

Taking the last first, two initial charge weights between 47 and 48gn looked promising with the 180gn JLK LBT VLD bullet, ‘LBT’ an abbreviation of Long Boat-tail, a very high BC design. This was in ‘prepped’ high-capacity Winchester brass matched to a Federal 210M match primer. Refining the load saw me settle on 47.7gn which produced a 0.35-inch 5-shot 100 yard group at 2738 fps. This is a modest MV for a long-range load, its 3000 ft/lb ME being the equivalent of a 155gn at ~2,950 fps or 100 fps below what I’d look for with the 32-inch barrel rifle. (Using this method, a 180gn bullet needs an MV somewhere between 2825 and 2850 fps to be in the same ballistics ballpark as the 155.5gn Berger at 3050 fps.)

It shot well enough to help me win the F/TR class in an 800-yard Diggle match, but for some reason wouldn’t perform nearly so well at 1000 yards at Bisley a few weeks later. The load wasn’t ‘hot’ in my rifle and the roomy brass, although it was shown as being maximum in QuickLOAD, so I could increase loads and try to find the next higher ‘accuracy node’ within acceptable pressures, or more practically stick with it at shorter ranges.

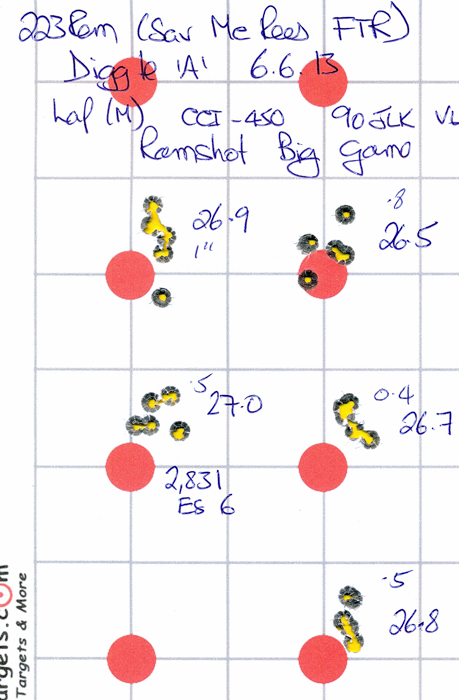

I also tried ‘Big Game’ in the 223 F/TR rifle with its ultra long-throat chamber and with the 90gn JLK VLD (Lapua ‘Match’ brass and CCI-450 SR Magnum primer). I thought the powder might be on the slow-burning side but it seemed fine. I expect 2800-2850 fps from VarGet and Reloder 15 under this bullet in its 28-inch barrel and my top Big Game charge of 27.0gn was right in the ballpark at 2831 fps with a brilliant spread of only 6fps and producing a half-inch group – on the upper side of acceptable.

The Savage PTA bolt lets you know if pressures are too high, through excessive primer extrusion and this load produced less than I get with the Hodgdon and Alliant duo, so I reckon I could finesse the weight up a bit and maybe tune the groups down to the 0.25-0.4in. levels I want. I’d also want to do this in warmer conditions, although this first try was on a pleasant early June day. (Note, these loads can only be used in a barrel chambered specially for 90gn bullets.) 80.5gn Berger BT Long-Range bullets were tried in the same rifle/chamber over ‘Wild Boar’ sharing the 90s’ brass and primer combo. MVs were excellent hitting 3081 fps with the top charge of 26.4gn and starting to show promise. With pressure also looking modest, this will be fine-tuned up a bit. (This bullet at 3000 fps or higher MVs is more than capable of taking on 308 in short / mid-range F/TR up to 800 yards, and offers potentially superior results providing the load groups well and consistently enough, in my opinion).

Short Barrel

I threw a quartet of TAC based loads together in 223 with a couple of 55gn bullets and Sierra’s 69 and 77gn MKs. The rifle had a bedding problem, now rectified, so there’s no sense in quoting the extremely mundane groups but also saw powder charges turn out to be too low with MVs 100-200 fps down on where they should be and with large spreads.

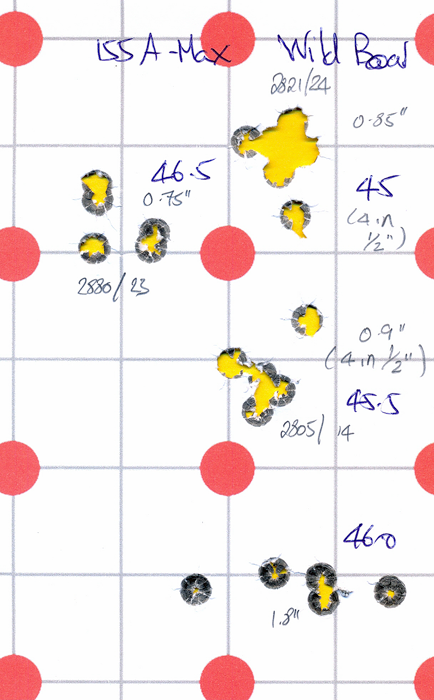

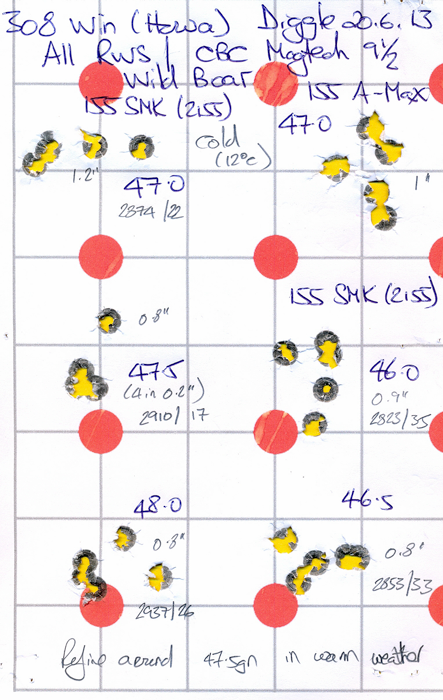

This may be an issue with TAC but I sincerely doubt it given its performance in the 308 Howa and 155gn Hornady A-Max and Sierra MK bullets. The rifle is basically factory, comes with a short (22-inch) 1-12 twist barrel and a long throat allowing 2.90 inch plus COALs with these bullets. Its only real change from ‘out of the box’ spec. is a basic bedding job.

With Viht N140/Commonside TR140, the 155gn pair will usually group into a half-inch at 100 yards, sometimes go smaller but only at modest MVs in the 2600-2650 fps band, the same applying to many other 308 propellant staples. Against this backdrop, TAC and Wild Boar produced impressive velocities, both coincidentally hitting 2937 fps with the Sierra and with small spreads by the Howa’s standards – a rifle that more often than not produces values in the 30-50 fps range.

I loaded the A-Maxes up a grain lower but still approached 2900 fps. Groups showed promise at 0.75-0.8 inches, often putting four into the half inch, or on one occasion a staggering 0.2-inch but spoiling things with a 5th thrown out vertically. This was in ex RUAG/NRA RWS brass with Brazilian CBC Magtech #9½ primers incidentally. Conditions were cold to cool and top loads were just starting to feel ‘hot’, so as well as finessing these loads, I’d want to try them in higher ambient conditions.

In summary, it’s early days but I’ve already seen promise from the three powders tried. Like many ball powders, the Ramshot numbers need loads that approach full working pressures before they really perform, so are sometimes not as flexible as extruded competitors and so take a bit of fine-tuning. Even so, a 2.0gn Wild Boar charge weight range in the Howa with the 155gn Hornady A-Max saw all five loads produce 5-shot velocity spreads between 11 and 24 fps which is the best string performance I’ve obtained from this rifle and its hammer forged factory barrel, by a large margin.

Important Notice

These loads were safe in the author’s rifle but may not be in others. Start well below quoted charge weights and work charges up in small steps looking for pressure signs. The 223 Rem 80.5gn and 90gn bullet loads apply ONLY to barrels throated specially for 90gn VLD bullets and must not be used in shorter-throated chambers.