I’ve saved what I consider the best to last, the three mid-size 6.5s – 260 Remington, 6.5x47mm Lapua, 6.5mm Hornady Creedmoor. I’d intended to cover the trio together but, they raise so many interesting and subtle issues, this part of the saga has taken up much more space than expected. So, I’m afraid you’ll have to be content with a separate episode for each one and we’ll start with the 260 Remington and I’ll follow up on the Lapua in pt.4 and the Creedmoor in pt.5. The three are currently on a roll with rapidly increased use in competition, vermin control and deerstalking – often all three roles in the one rifle, such is their flexibility.

Left to right: 6.5X47mm Lapua; 260 Remington; 6.5mm Hornady Creedmoor

They are designed for short-action rifles and with COALs bracketing 2.800”, fit comfortably in standard length internal sporting rifle magazines, also high-capacity detachable box types. They feed perfectly and, whilst our use is in conventional turn-bolt rifles, their popularity among Americans is partially linked to a surge of interest in ‘big ARs’. (As I write, Savage has just entered the American ‘MSR’ – Modern Sporting Rifles – category including two AR-10 types. The MSR 10 Hunter and Long Range models only have 308 Win or 6.5mm Creedmoor chambering options showing how the latter has quickly become an equivalent to the venerable Winchester cartridge in the multi-purpose role.)

The basic mid-size cartridge rimless case-head design with its 0.473” diameter and standard extractor groove dimensions whose origins go back to the 7.9x57mm Mauser of 1888 via the 30-06 and 308 are used, so they fit in easily with manufacturers’ existing rifle models and allow straight rebarrelling of a shot-out 22-250 Rem, 243 Win, or 308 bolt-action rifle.

My FN SPR A2/A4 test rig – originally 308 Win, rebarrelled to 260 Rem.

Oldie

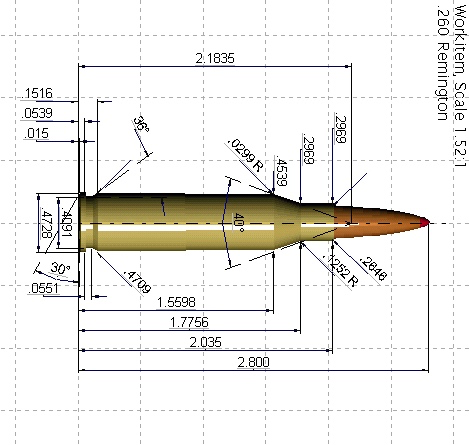

Starting with the oldest model of the trio, Remington’s 260 is little more than a necked-down 308 Winchester retaining its 20-degree shoulder angle and body taper. To obtain a reasonable (0.259”) neck length, its overall case-length was increased marginally (2.035” v 2.015”). Internal capacity is virtually unchanged. It was preceded by various 6.5mm-08 wildcats, some incorporating variations from simple necking-down of a 308 case as well as minor chamber dimensional differences to suit the favoured donor brass being used.

A-Square LLC, a SAAMI member, submitted cartridge and chamber drawings for a regularised version to be called the 6.5-08 A-Square in 1996 but then encountered delays in its registration which ended with the Standards body announcing the following year that it had accepted an apparently later submission from Remington for what was essentially the same thing. This caused some upset as it seemed the big boys could ride roughshod over small outfits but was presumably done in the belief that Remington would provide a great deal more support to the newcomer and enhance its chances of success – previous 6.5s having flopped in the US market.

As well as launching it with a reasonable range of factory sporting loadings, the Remington Arms side of the business chambered the new design in a fair number of rifle models. It could be had initially in the mainstream 700BDL and CDL rifles, a special law enforcement 700 and the one which the company pushed hardest in marketing terms, its lightweight super-short action Model 7 in various configurations including a youth model.

Lightweight

Remington marketed its new cartridge and the Model 7 (or ‘Seven’, as the company has used both designations) combination as the ideal youths’ and ladies’ deer-hunting outfit – lightweight, fast-handling, low recoil. Unfortunately, as originally loaded the cartridge was also a rather low performance number especially in the 7’s short barrel. It allegedly produced similar ballistics to appallingly under-achieving contemporary American 6.5x55mm loadings, as much as 200 fps shy of the claimed performance of 2,750 fps with 140gn bullets.

Whilst Remington saw the Model 7/260 combination as a marketing USP (unique selling proposition), the strategy may have backfired as many of America’s primarily male hunters apparently wrote the cartridge off as ‘only suitable for women and kids’.

For whatever reasons, the cartridge had a long period in the doldrums with little interest from other mainstream rifle or ammunition manufacturers. Remington soon dropped it from its 700s restricting it to the Model 7. (Current listings are for the quasi-tactical M700 VTR, the basic plastic stocked 700SPS and three Model 7 variants, so things have improved. So far as the Model 7 goes, it went on to earn more praise as a deer-hunting rifle through its later pairing with another Remington developed 308 Win offshoot, the 7mm-08 Rem cartridge). To put the cartridge’s UK usage into perspective, I did a Guntrader UK new and used rifle search and found only nine 260s listed – compared to over 150 6.5x55s, 750 243s and 500 308s!

Centre 260 Rem, left 243 and right the 7mm-08 Rem. Far right, the ‘parent’ 308 Win

Factory Fodder

US ammunition giant Winchester never adopted it, nor made brass. For many years Remington brass had a reputation for ‘soft’ case-heads that saw primer pockets quickly slacken with full-pressure handloads. As many American handloaders prefer Winchester over Remington, a common ploy was to buy the former’s 7mm-08 cases and neck them down by a simple run through a 260 full length sizing die followed by trimming to 2.035”. Alternatively, Winchester or Lapua 243 Win could be necked-up, but that usually creates a small radius at the case-neck/shoulder junction which, on firing forms the very undesirable internal ‘doughnut’ or ring.

These issues largely went away when Lapua started production of the case in 2011 and Nosler has had premium ‘Custom’ brand 260 Rem cases on sale for at least as long. (In some parts of the world, performance orientated users neck very robust Lapua 308 Win ‘Palma’ small primer cases down to 260. This involves a bit more work than a simple resize though).

Remington and Nosler 260, Winchester 7mm-08, Lapua 308 Palma brass

Even today, factory ammo is thin on the ground but things have improved with Hornady, Nosler and Federal adding the 260 to their ammunition ranges alongside brass; Norma and Lapua unprimed cases only. Nobody complains about today’s factory ammo being seriously under loaded anymore. American specialist ammunition producers – Cor-Bon, Black Hills and Berger Bullets’ ammunition manufacturing subsidiary ABM load the 260; ABM recently launched ‘Mission Ready’ and ‘Match Ready’ loadings with 130gn and 140 Bergers respectively. Bob Forker lists 17 loadings from five manufacturers in Ammo and Ballistics 5, but as with the 6.5×55 and 6.5-284 understates the position as no fewer than five Hunting Shack lines (branded HSM) are omitted, these including 123gn Lapua Scenar and 142 Sierra MK match loads.

So, with these and ABM’s pair there are maybe some 24 or 25 factory offerings potentially available in the USA. Here in GB, we’d see nothing like that number in our gunshops as HSM, ABM, Cor-Bon, Black Hills products aren’t exported and, it’s often hard finding ‘mainstream’ Federal, Remington, or Nosler versions. Of the European ammunition manufacturers, only Sako loads it, so no cheap PPU, S&B and suchlike.

HSM (Hunting Shack) loads five .260 Rem products for the American market.

Partition

Another early 260 problem was limited bullet choice but this has long since been rectified with many superb match and expanding designs available. Some, such as 100 and 120gn Nosler Partitions introduced with the 260 specifically in mind. A few years back, I had a conversation with top custom sporting rifle gunsmith Callum Ferguson of Precision Rifle Services fame about this cartridge – he’s a fan. The Scottish Highlands based rifle builder uses a short-freebore chamber that suits varmint bullets to provide match level precision but … and this is the critical part … will still cope happily with the 100gn Partition deer bullet and produce good velocities. Callum says the set-up allows long shots on foxes and corvids on open Highland glens, with the Partition still fully up to the job of dropping red deer.

Benchmark

The 260 is, in many ways, our mid-size 6.5mm benchmark. It has been around longest; it has recently done well in terms of interest, handloading tool sales, component availability. It has the largest internal capacity of the trio but only marginally but countering that, the lowest allowed maximum pressure. Incidentally, mentioning capacity, QuickLOAD’s default ‘overflow water capacity’ value appears to be on the low side at 53.5gn. Fired cases from my rifle’s chamber vary between 54.4gn (Federal) and 56.6gn (Remington) water capacity, Lapua mid way between them at 55.1gn. This may seem trivial but it affects results in QuickLOAD modelling, real life handloading too as a maximum load in Remington brass would probably be over-pressure in Federal. This is why handloading manuals quote the components used in their test loads and caution that

results/maximum loads apply to that combination alone.

There are significant case capacity differences between makes of 260

Taking COAL to …

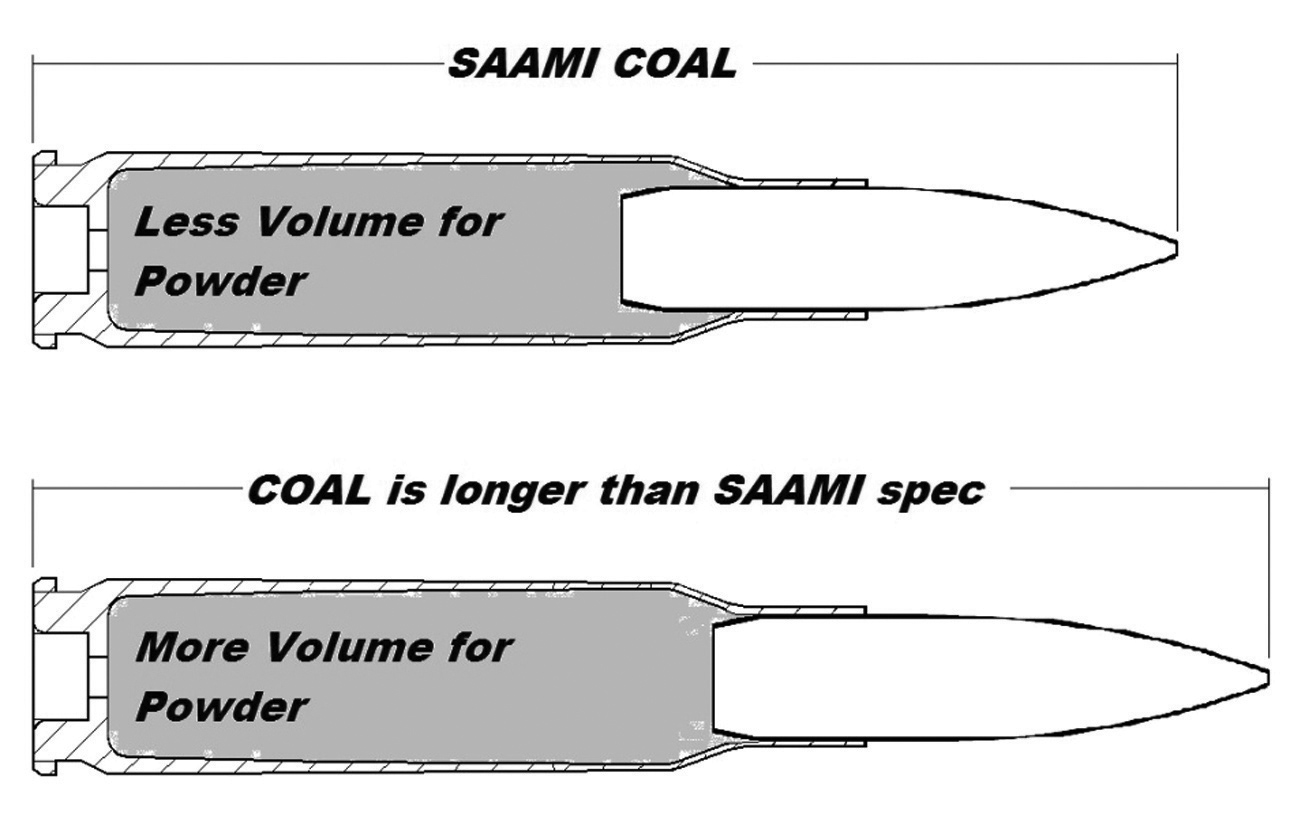

A common criticism of the 260 is an apparent bullet length v cartridge length (COAL) mismatch. The issue here is the design’s provenance, a descendant of the 7.62 Nato via 308 Winchester. The 7.62 was designed around 144-146gn FMJBT bullets whose lengths run at around 1.1-inches. With a nominal COAL of 2.750” and a case-length of 2.015”. Subtract one from the other and around 0.74-0.75” of bullet sticks out of the front end of the case, meaning 0.35-0.4” of the just over an inch-long projectile is inside the case-neck. When Winchester took the design and modified it for civilian use the COAL was increased to 2.810-inch (SAAMI) to suit longer 150-180gn match and sporting bullets, and since then (1952), everybody has designed ‘short actions’, magazines and new cartridges around this parameter.

Optimal and over-deep bullet seating, the latter a common 260 Rem problem

When we look at the 260 Rem, we find a case that is 2.035” max length, neck length of 0.259” and SAAMI COAL of 2.800” but, bullets that are, in match form, typically 1.3 – 1.4” long. If we have to stay within 2.8” overall, we can have 0.765” of bullet projecting outside of the neck (2.800 – 2.035”) so, if our bullet of choice measures 1.3”, 0.535” (1.3 – 0.765”) has to be inside the case, 0.635” if the bullet OAL is at the 1.4-inch mark as are some 140s. With a 0.259-inch long neck, we have 0.375 to 0.475” inch of bullet shank/tail section hanging below the bottom of the case-neck, almost right on the half-inch mark if you must shoot the new Berger 140gn Hybrid in your 260 at this COAL. That’s a lot of intrusion into a case that’s two-inches outside length, considerably less so internally.

144gn 7.62mm bullet (left) against Berger 6.5mm 140gn VLD

But … do you have to load your 260 ammunition to 2.800” COAL? The actual usable COAL is partly determined by whether magazine operation is needed and if so, what is the maximum COAL the action/magazine will function with reliably. My 260 is a rebarrelled 308 Win FN SPR A2/A4 with a 4-round detachable box magazine and its fodder has to be kept below 2.800” or it won’t fit, period.

The FN SPR magazine needs COALs under 2.8 inches ……….

The Precision Rifle Blog, online home of US ‘tactical competitors’, says the widely used Accuracy International box mags usually work reliably with cartridges up to 2.880-inch, so you have a little more leeway there. 0.080” may not sound a lot but it’s well worth having with some powder/bullet combinations.

…………. whilst the AI magazine may work reliably with COALs up to 2.880”

That’s the mechanical part but, if you single-load as I do with the FN, the 2.800” limit doesn’t affect you anyway. In all scenarios, whether single-shot or magazine feed is envisaged, chamber freebore is the other relevant factor. What will your rifle accept before the bullet hits the rifling lands? My 260, chambered with what I believe is a standard-spec reamer sees the following COALs with Lapua Scenars positioned 0.015” (15 thou’) short of the rifling lands: 108gn – 2.875”; 123gn – 2.885”; 139gn – 2.870”.

So, if I were loading for a CSR/McQueen/Tactical job using AI magazines, we’d be hunky-dory at those values, just having to accept marginally deeper seating and a few more thou’ jump for the 123gn version. However, should I want to use the 130gn Berger VLD in my chamber, it needs a 2.960” COAL with the bullet just into the lands, or 2.920” with a largish ‘jump’, so the AI magazine-fed option doesn’t look too good. (There is now a potentially viable alternative option which I’ll come to in due course).

At those 108-139gn Scenar COALs, how deeply are bullet-shanks seated? The optimal seating position sees the bottom edge of the bullet’s parallel section (shank) marginally above the case-neck/shoulder junction line, as per the diagram below – in the 260’s situation that’s ~0.26-inch below the case mouth. At the usable COALs I’ve quoted that suit my rifle’s throating in either single or AI magazine feed, the 108 and 123gn Scenars are seated ideally with 0.237”and 0.231” of shank in the case-neck. The 139-grainer does intrude more with 0.313” of shank inside, that is extending some 40-thou’ below the bottom of the case-neck – not optimal but, we can live with that.

In my chamber, the single-loading COAL with the bullet mildly ‘in the lands’ sees the 130gn VLD bullet some 12 thou’ deeper seated than optimal but if I had to restrict the COAL to 2.880” for the AI magazine, that increases to just over 90 thou’ and if the FN magazine’s 2.800” COAL were to become the limiting factor, 0.171” of bullet shank is now positioned below the case-neck. Taking the tail section into account too, that sees 0.370” of bullet rear-end inside the case body section. The even longer 140gn Bergers will see yet greater lengths of bullet competing with the powder-charge for room below the neck in such situations, assuming an ideal charge fills the case to the top of the shoulders before the bullet is seated.

Bullet base positions in 260

Meaning …?

Right .. I sympathise! You’re screaming ‘Too much detail, too many figures!’ So, what conclusions can we draw? Firstly, if you really are stuck with a 2.800-inch COAL, the 260’s set-up is sub-optimal with nearly all HPBT or tipped match bullets giving over-deep seating positions. However, if you’re single-loading or have a rifle using AI magazines and provided you don’t load really long 130gn and heavier VLDs plus the 140gn Hybrid, there isn’t a problem.

I also did a lot of QuickLOAD modelling to see how much effect over-deep seated bullets have on fill-ratio levels, and achievable pressures/velocities. My findings were that with a high-BC but not too long bullet (eg the 139gn Lapua Scenar), the effect depends greatly on powder choice – a deep seated 139 Scenar at 2.800” COAL seriously limits how much Viht N160 can be used before excessive charge compression levels are reached. Between extreme scenarios of the short SAAMI COAL and bullets seated optimally at over 2.9” COAL, there was a projected 3gn charge difference and 122 fps MV range with this bullet-powder combination.

However, switch to a higher energy, denser propellant, Viht N560 in lieu of N160 say and the extreme COAL-induced difference drops to a mere 25 fps. Modelling a range of high-energy types suitable for the 260 came up in each case with 25-30 fps velocity loss for the restrictive 2.800-inch COAL compared to long-throat versions. So, the 260’s ‘problem’ is less about absolute performance, more restrictions on powder and bullet choices.

And … this cartridge offers good performance. Without going mad on pressures, a 26-inch barrel 260 rifle with my chamber is likely to approach 3,000 fps with the ballistically outstanding 123gn Lapua Scenar using high-energy added nitroglycerin type propellants such as N560 and Re17/RS60; around 2,900 fps from cooler burning single-based extruded types. Knock 100-150 fps off these figures for 140s.

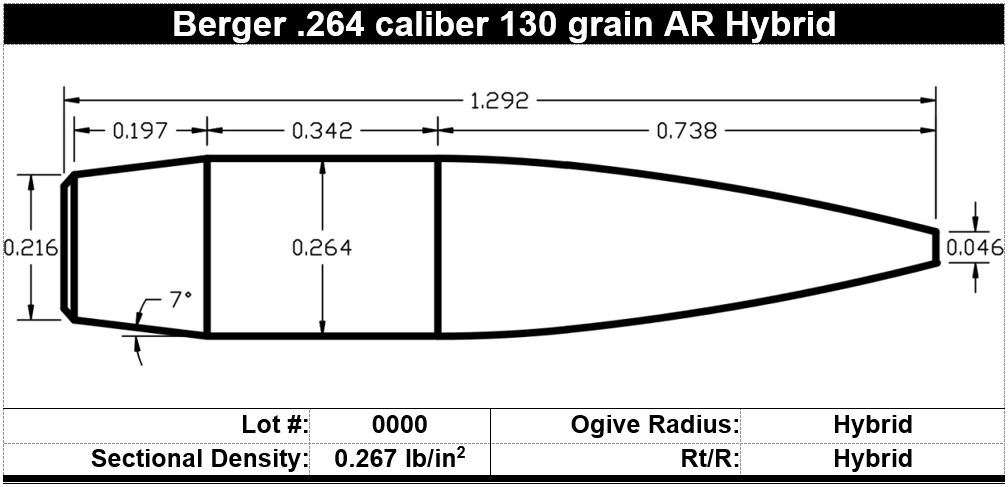

‘AR-Hybrid’

At this point, I’ll mention a recent innovation from the ever-inventive Mr. Bryan Litz of Applied Ballistics LLC and Berger Bullets fame – the Berger 130gn AR-Hybrid (Figure 3). As the name suggests, it was designed for semi-auto AR-type rifles that really are restricted to a 2.800” or shorter COAL more often than not. The conundrum was how to get as heavy and as high BC a bullet as possible fitting into the COAL, whilst minimising intrusion into the combustion chamber space.

Answer: a cleverly designed Hybrid [ogive]-nose form but with a SAAMI length nose in lieu of the much longer equivalents on the ‘Target Hybrid’ and VLD designs. Throw in a short shank and optimal angle boat-tail and you have an aerodynamically efficient bullet in an ideal weight for the smaller 6.5s, can be seated to fit action and magazine constraints and all whilst minimising base intrusion into the combustion chamber.

Average BCs are 0.564 (G1) and 0.290 (G7). That’s nearly identical to the same weight VLD but with a full tenth of an inch OAL reduction and in a design which should also be much more jump-tolerant than the secant-ogive VLD. It’s actually marginally shorter than the 123gn Scenar but offers a considerable BC gain. Whilst designed for AR-10s and suchlike, it’ll offer the same benefits to short-action bolt-action rifle users. These bullets have only just arrived at Hannams Reloading and I’ll try the design in 260 Rem later this year. Be warned though – this is no pauper’s product with Hannam’s RRP over £56/100! Incidentally, many people say they can’t find these bullets in Berger’s product/specifications listings. That’s because you need to look in the small ‘Tactical’ section, not ‘Target’.

130gn Berger AR-Hybrid (left) and 130gn VLD bullets at ideal settings for my rifle’s chamber. Being a ‘Tactical’ product, the former comes in Berger’s cream boxes.

Next time – the 6.5×47 Lapua.