Hodgdon H4895 and VarGet Alternatives Part 4

WARNING

The load data contained on this site is intended for use with specific rifles and components. Other manufacturers’ equipment will not produce equivalent pressures or velocities. Data contained herein is therefore for the purpose of comparing loads and results against the Reach-ban benchmark grades only, and are not intended for use by individuals – even those who are familiar with correct and safe handloading practices and procedures.

Target Shooter has not set out to produce reloading data but rather to offer alternatives to powders now unavailable due to REACH controls and it is up to the reader to interpret this data to suit his or her requirements and thus no responsibility is assumed in the use of this data. The information is to be used at the sole discretion of the user and the user assumes all risk.

To complete the section on extruded H4895 alternatives, I’ll cover the four products that recently slipped out of our grasp: IMR-4166 ‘Enduron’; Norma 201 and 202; Viht N530. IMR-4166 has been discontinued by Hodgdon, IMR’s owner, although there is apparently a chance that it and the other ‘Endurons’ will be reinstated if manufacturing problems can be resolved. 201 and 202, alongside the rest of the Norma range are still in production (or at any rate, listed), but our distributor RUAG Ammotec UK has stopped importing them. Finally, Viht N530 has gone because its manufacturer is under enormous pressure to increase output and this minor grade requires an excessive level of resources for its production runs. So, why write them up? Simply, whenever a powder disappears for whatever reason, quantities usually remain around for years, acquiring new applications or being resold.

Before moving on to the powders, a reminder on kit and components. The rifle is a Savage PTA based F-Class job with a heavy-profile 7-twist 30-inch Benchmark chambered in ‘minimum-SAAMI’ 223 with a freebore length 100+ thou’ longer than standard (25-thou’ freebore) SAAMI as used by the bullet, powder and ammunition companies in their pressure-barrels. Cases are recent .223 Lapua ‘Match’; primers old Russian manufactured PMC SRMs (mild contents but strong cup); bullet the 77gn Sierra MK seated to 2.400” to suit the long-freebore chamber. The chamber allows higher charges than used in reloading manuals; that and the barrel length produce considerably higher MVs within safe pressures.

IMR-4166 ‘Enduron’

I could make a terrible pun and say this powder, introduced in 2015, hasn’t endured long, especially with some IMR ‘legacy’ grades having been around since before WW2. So, is it a star performer whose loss will leave handloaders bereft? It should be, given its relatively recent introduction having been developed / manufactured in a modern high-tech plant (General Dynamics’ Valleyfield facility in Quebec province, Canada) on behalf of the USA’s leading powder supplier Hodgdon. To answer my own question, I would have to respond with a Delphic “It depends …”.

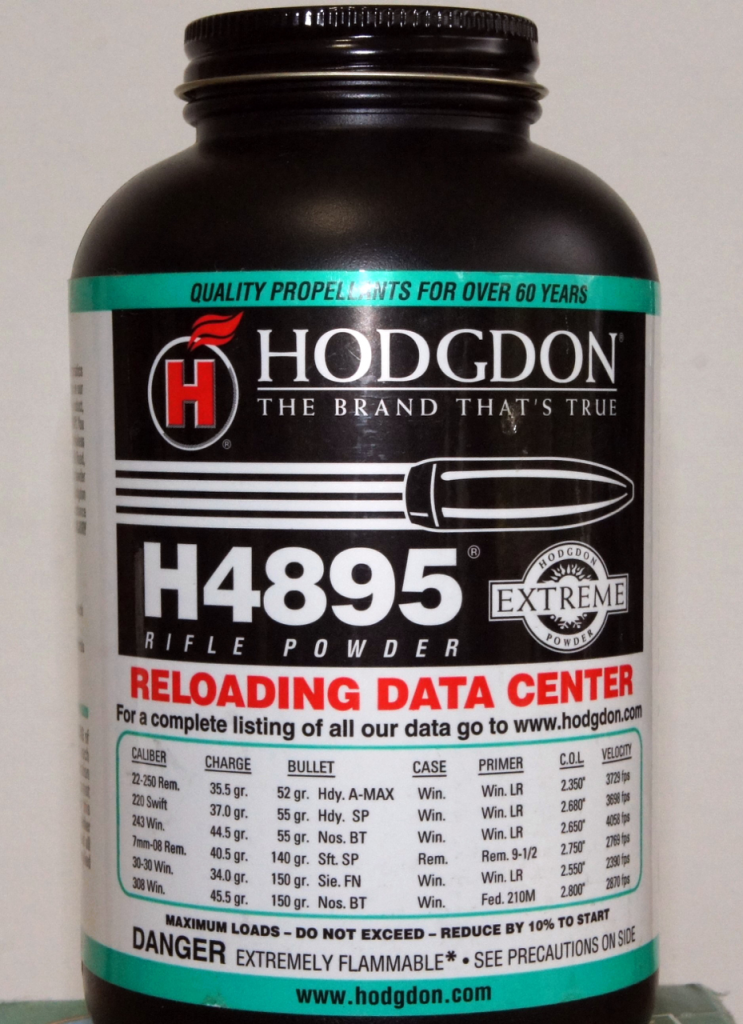

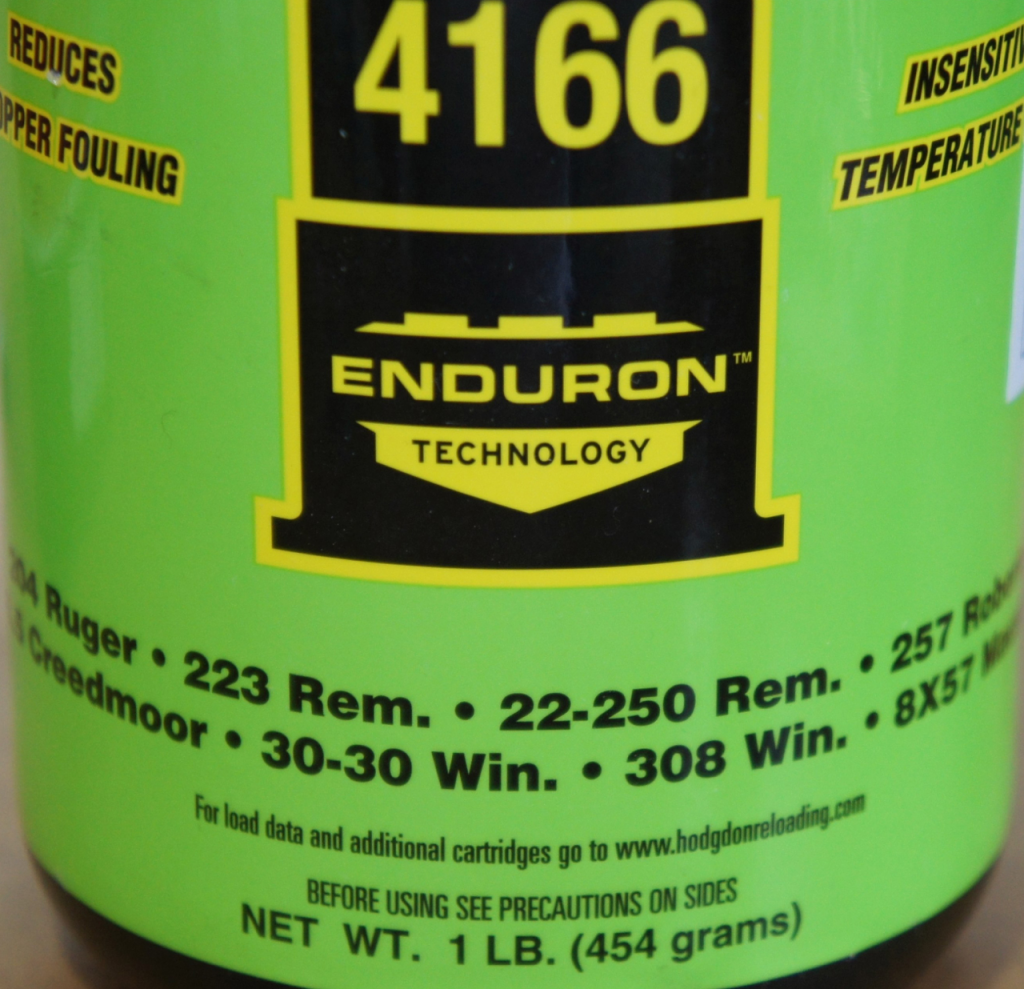

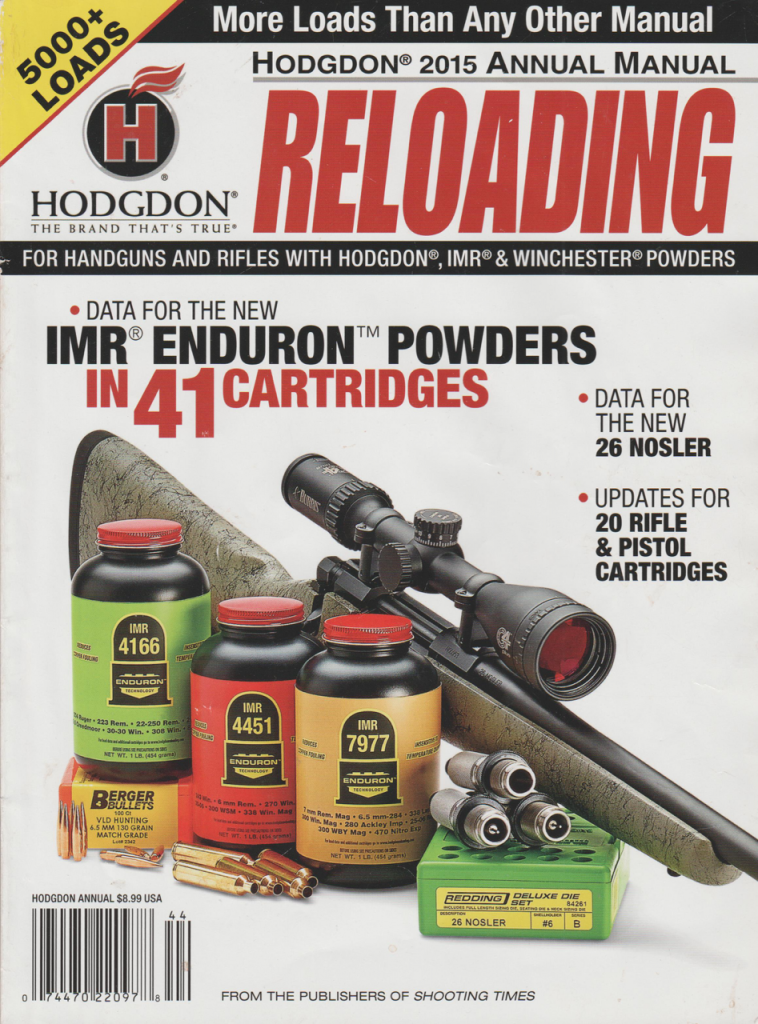

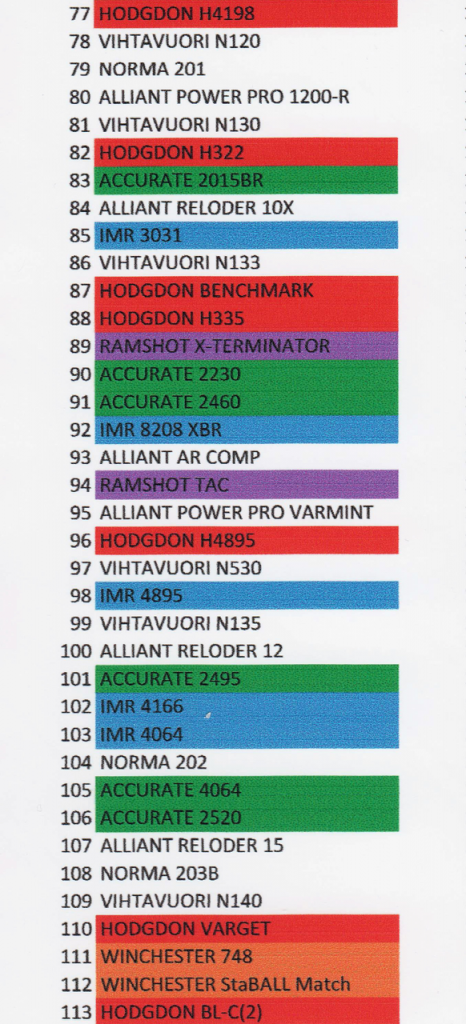

Its claimed selling points were excellent temperature stability; met all environmental regulations; high fill-ratios in medium cases; an incorporated anti-coppering agent. Given the supply constraints of and insatiable demand for Hodgdon’s ADI manufactured ‘Extreme’ powders (H4895, VGT etc), and the emergence of regulations such as ‘Reach’ that these grades don’t meet, the ‘Endurons’ had to be very important products to Hodgdon, so much so that the first three to be introduced featured on the cover of the 2015 Hodgdon Annual Manual and were the subjects of the lead articles inside, 4166 itself tested in no fewer than eight cartridges in nine rifles by a top American shooting writer in a seven-page feature. Hodgdon’s burn-rate chart shows it at No. 102 with H4895 and Viht N135 on its ‘quicker’ side; IMR-4064, Norma 202, 203-B/Alliant Re15, Viht N140 and VGT shown as ‘slower’ (Figure 1 shows an extract). In other words, smack in the middle of a bunch of powders ideally suited to 223 Rem and 308 Win, also many other popular cartridges. As with the other ‘Endurons’, it is double-based, Handloader magazine’s reviewer ascribing 10% nitroglycerin by weight, so should theoretically have a healthy specific energy value.

I began to wonder about the powder though when researching test loads for 223 Rem. Other than Hodgdon’s own data in its Annual Manuals and website, there were none for this cartridge. Although it had then been around for some years, none of the recent editions of reloading manuals from the bullet companies (or their online data) listed any 223 loads (since rectified in Lyman 51st edition.) They did contain 4166 data for 308 Winchester, .30-06 with light bullets, and some other numbers. Online searches produced little further enlightenment. “Alright,” you might say: “4166 isn’t suitable for this cartridge – get over it!” However, every bit of information about the propellant points to it being a natural fit. For that matter, eight cartridges from 204 Ruger to 8mm Mauser feature on the can label, the second of which is, you guessed it, 223 Rem! And John Barsness’ seven-page 4166 Annual Manual write-up with nine cartridges in eight rifles not only included 223, but that was the cartridge tested twice – in an AR-15 and bolt-action ‘varmint’ rifle. In any event, it is inconceivable that any recently introduced powder in this bracket would be unsuitable for the application given American shooters’ vast consumption of the 223 Rem and the equally vast quantities being handloaded.

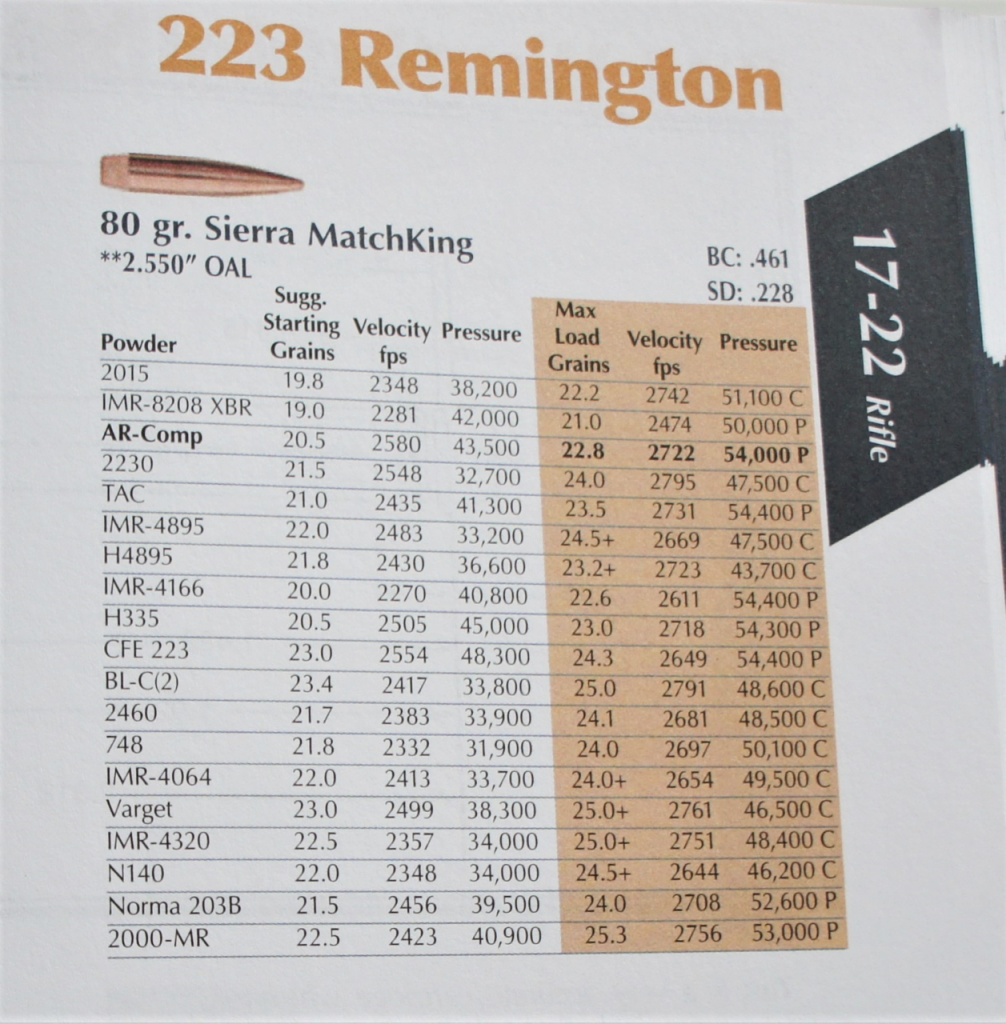

What do the Hodgdon and Lyman manuals show, not to forget QuickLOAD (QL) with 4166 being in the current v.3.9 database? Both published sources provide loads for 50-77gn bullets in the 223, Lyman going heavier by including the 80 and 90gn Sierra MKs. For the 77gn SMK I was loading, both give a maximum charge of 22.0gn for the short-freebore SAAMI chamber / 2.26-inch COAL loading, down on either H4895 or VarGet charge weights, moreover a very low weight relative to other grades if its position in Hodgdon’s own burn-rate chart is to be taken seriously. This isn’t a compressed load either, unlike those of our two Hodgdon benchmark grades, and both manuals show their maximum 4166 charges’ pressures approaching the 55,000 psi SAAMI ceiling, apparently the limiting factor. Despite this, Hodgdon’s own Annual Manuals’ data show 4166 producing the second lowest MV in the 77gn SMK table improving only on IMR-4320, and at 2,663 fps some 45 and 74 fps shy of H4895 and VarGet speeds respectively (24-inch test barrel). Lyman’s 77gn SMK results from velocity-testing in a 20-inch AR-15 barrel are in relative terms worse, 4166 producing the lowest recorded velocity of the 19 powders in the table and 113 fps shy of the VGT result. Lyman doesn’t include H4895 in this table, but does in its 80gn SMK data where the 4166 ‘velocity-shortfall’ is 112 fps against H4895 and no less than 150 fps for VGT (Figure 2). Looking at published 308 Win 4166 loads data in the latest Lyman and Sierra manual editions a similar if less striking pattern emerges of rather low speeds compared to apparent equivalents.

Loads and Results

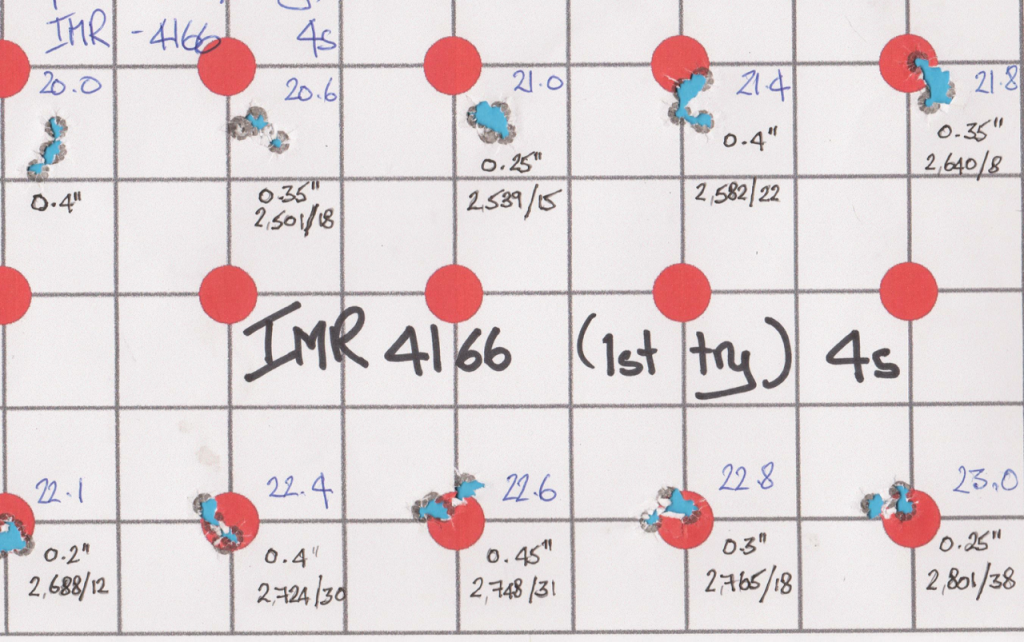

These low MVs probably explain the powder’s no-show in reloading manuals. With too many potentially 223-suitable powders available to include everything, the bullet companies’ reloading manual compilers omit grades that are speed-deficient. However, I was reluctant to assume that was the sole, or even primary, reason and had concerns that 4166 would produce some sort of unpleasantness if an invisible charge weight line was crossed, so proceeded very warily. My first attempt saw 10 four-round batches loaded up rising from Hodgdon’s starting load to 23.0gn, 1gn above its published maximum with 0.2gn final increments. (Remember that with my long-freebore 223 match chamber and bullets seated well out, pressures are reduced and I can increase charges by nearly a full grain weight over published loads that had been tested in a short-freebore SAAMI-spec chamber with cartridges loaded to 2.26” OAL. 23gn in my rifle/chamber is therefore only marginally higher than the pressure barrel-tested 22gn.)

No problems arose except that my 23gn top load only produced 2,801 fps compared to the benchmark 24gn H4895 2,980 fps MV, moreover a 100 fps or more reduction against nearly every other powder tested in the series. Groups were excellent ranging from 0.2 to 0.45-inch. I had by now acquired QL v.3.9 and the actual MV, low as it was, exceeded the QL prediction, the program calculating 2,747 fps at 45,529 psi Pmax for 23gn in my long-freebore chamber. 2,800 fps was calculated to need around 48,500 psi, still well below 223 peak, or even normal, working pressures.

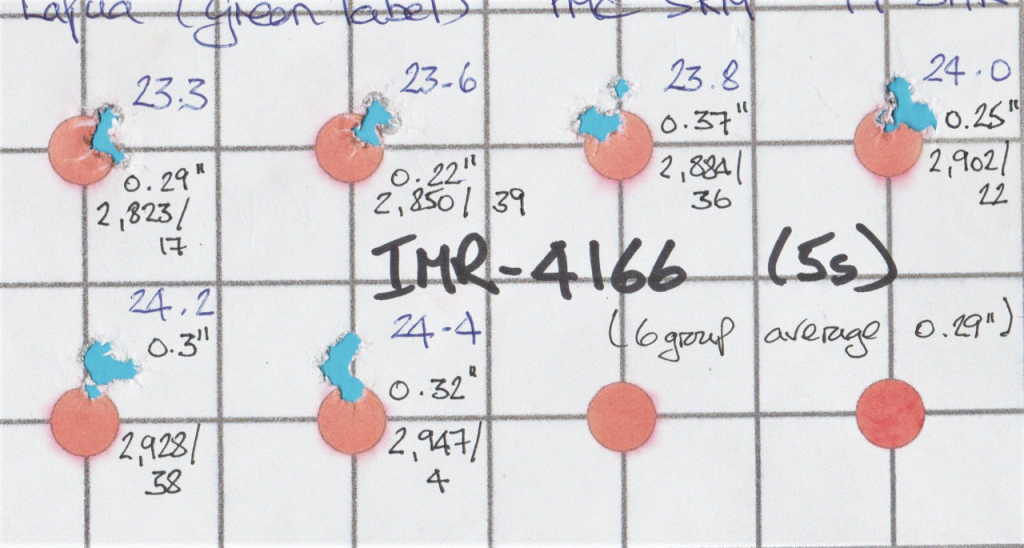

That emboldened me to increase charges further to 24.4gn, six 5-round batches loaded with small weight increments. The top load raised the MV to 2,947 fps on the Labradar, QL reckoning on just over 57,000 psi being produced at that speed. Bear in mind that even with my long-freebore chamber effect, I was now running at an equivalent 1.6gn above the two manuals’ maximum load, a VERY great deal in this cartridge and normally not to be contemplated let alone tried in a treasured rifle! So far as conventional pressure indications went, there were no MV (hence pressure) spikes with any charge weight increment and the top 24.4gn load was just starting to flatten the PMC SRM primers, also injecting vertical into the group shape. For these reasons, I reckoned 24.4gn was seeing the powder start to pressure-out and that QL’s calculated 57,000 psi likely underestimated the real level. It looks like the ceiling was around 24.0gn, more likely a bit lower still. Therefore, playing safe, I would have ended up somewhere between 2,850 and 2,884 fps as produced by my 23.6 and 23.8gn charges, the former 130 fps below the H4895 benchmark speed, and in line with Lyman’s findings.

So, not a good result for MVs. There was an upside – excellent and very consistent precision. Yet again, this second lot of six batches was shot on that dreadful mid-November day as per Viht N540 and Reload Swiss RS40 (Reach Out – 7 and 8), and for a third time results were exceptional. Serendipity, or maybe the nut behind the butt tries that bit harder when it’s difficult to see the aiming mark? Groups, and these are all five-shot not the usual four, ranged from 0.22 to 0.37-inch, the six averaging an excellent 0.29-inch, one of the smaller ‘aggs’ of the test series – not so shabby after all. POI elevation barely rose across all charge weights from 22.1gn and although ES values varied across charge weights, there were some small examples. So, if you’re willing to forego speed, 4166 is an excellent choice in a range of popular cartridges, not only 223.

R H VanDenburg Jr obtained similar results across several cartridges in his 2015 tests for Handloader magazine – ie low velocities, but good groups and often very small SD values. One exception to the low MVs pattern was 8mm Mauser shot in a modern Remington 700 where readings were comparable to those produced by other powders, while groups / SDs remained good. This made me wonder about 4166 in our .303. Hodgdon provides data for both it and the 8mm Mauser, and according to the company’s tables, MVs are apparently OK here too. So, historic arms shooters struggling for powders and finding any 4166 might consider grabbing it while it is still available.

Overall, I’m puzzled by the discrepancies between the propellant’s specification, Hodgdon’s and Lyman’s pressure barrel-tested data, QL v.3.9. predictions, and actual performance. With Hodgdon and Lyman showing measured chamber pressures of 53,600 and 53,800 psi respectively for their 22.0gn 4166 77gn SMK maximum charges against the allowed SAAMI 55,000 psi, I must advise that people do not exceed those charges in factory 223 Rem chambered rifles (or the recommendations for any other cartridge), and live with the resulting low MVs.

Swedish Siblings

Alphabetic order takes us next to the Norma pair – 201 and 202. As with all Norma rifle powders, they are double-based and manufactured by Eurenco Bofors in Sweden (which also makes the majority of Alliant ‘Reloder’ grades). I say double-based, but they’re only mildly so with 4.5% nitroglycerin in the mix. This pair are identical bar one crucial feature. Same dimensions; same primary ingredients (88% nitrocellulose; 4.5% nitroglycerin); same bulk density (880 grams / litre); similar energy (3894 and 3852 J/g for 201 and 202 respectively). The difference is in the weight / thickness of the burn deterrent coating, 202 having more to slow the initial burn for longer. Those energy figures position the pair midway between most single-based rifle powders such as Viht N135 / Reload Swiss RS50 and the hotter high-energy types such as N540 and RS52. Dimensionally, they are a slightly longer cut at 1.1mm than the comparable Viht grades which measure 1.0mm for both N135 and N140, but at 0.72mm diameter are ‘skinnier’ (N135 is nominally 0.8mm; N140 0.9mm). All four Norma and Viht grades are shorter-cut than the benchmark H4895, so should meter at least as well in volumetric powder measures and my RCBS ChargeMaster produced exceptionally consistent charges with the pair.

Looking at their ‘quickness’, they are respectively the 2nd and 3rd fastest burners in the Norma eight-powder strong rifle powders lineup, only 200 being ‘quicker’. The next ‘slowest’ burner is Norma 203-B aka Alliant Reloder 15 – see Reach Out-6 which looks at VarGet alternatives. In some burn rate charts, 201 and 202 are shown close together and bracketing H4895, 201 only a tad ‘faster’; 202 ‘slower’ and aligned with VGT. However, others show 201 as being much faster burning than either H4895 or its Norma 202 stablemate, and this applies to the aforementioned Hodgdon list which puts 201 between Viht N120 and 130 (Figure 1).

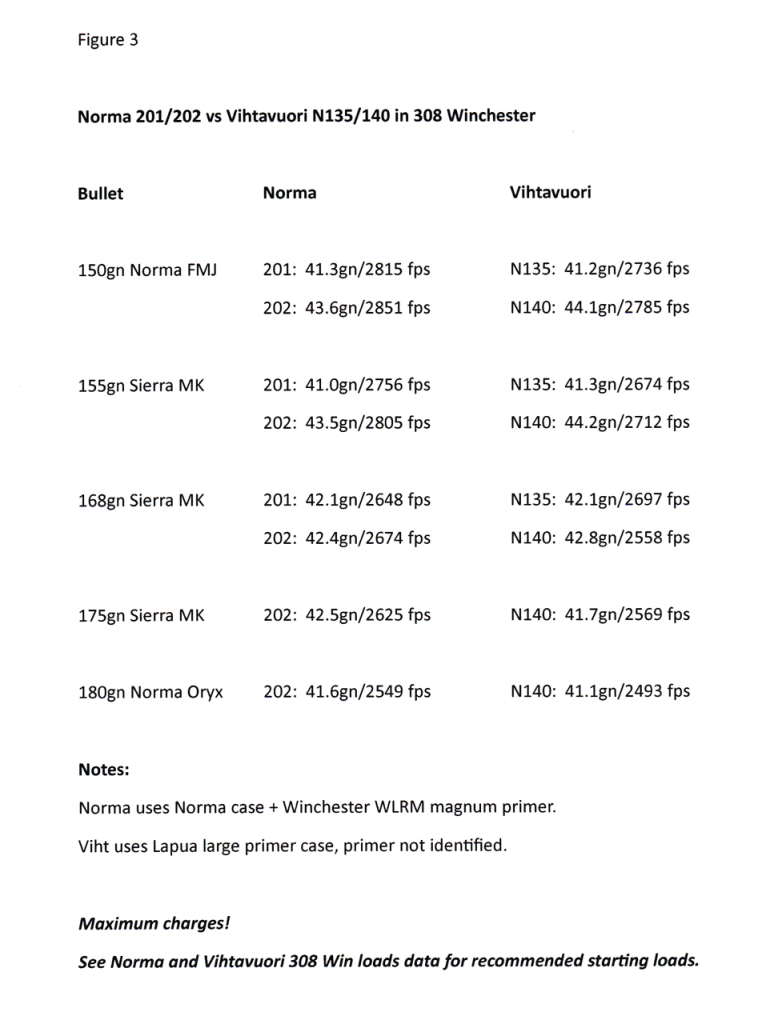

As Norma powders were last seen here well over a quarter century ago, and RUAG Ammotec UK’s reintroduction was so brief, it’s difficult for UK handloaders to get a handle on these powders as to applications and known equivalents. Norma’s product descriptions often don’t help overmuch either (with the exception of 202 which Norma says was developed to maximise performance in the 7.62 NATO military application). However, for this pair, Norma and Vihtavuori have five 150-180gn weight bullets in common in their 308 Win pressure barrel-tested loads tables. When I say ‘five bullets’, I mean bullets as in models, not same weight but different designs. Comparing maximum charges and their MVs extracted from the 2nd edition of Norma’s Reloading Manual and Viht’s current comprehensive online data, one can see that in 308 Winchester anyway, Norma 201’s top charges are close to those of Viht N135 and 202’s likewise for N140, the latter running up to 0.7gn lower than the Finnish grade for 150 to 168gn bullets, then slightly exceeding them for the 175 and 180gn models (Figure 3). The Norma powders’ MVs are generally higher than their Viht equivalents in these data, both powder manufacturers using a 24-inch test barrel. I’ll stress that I‘m not producing this for readers to transpose Viht N135/140 data across to other powders (extremely unwise!), but to suggest comparable and familiar benchmark grades to help identify potentially suitable applications. Whilst on this subject of Norma published data, there are three slight peculiarities worth mentioning: starting loads are closer to maxima than in most companies’ equivalents; Norma uses a Magnum primer in all Large Rifle primed cases, the very hot Winchester WLRM for 308 Win, and this will push MVs up (ES/SD values too). Thirdly, whilst most powder companies publish loads for any powder in their product range that is compatible with the cartridge and bullet weight, even if a trifle sub-optimal, Norma only lists its most suitable powders. In 223, 201 loads data stop with the 69gn SMK while Viht goes up to the 88gn Hornady ELD-M with N135 (and the still faster burning N133 for that matter); in 308 Win Norma drops 201 after the 168gn SMK, while Viht continues up to the 190gn MK with N135.

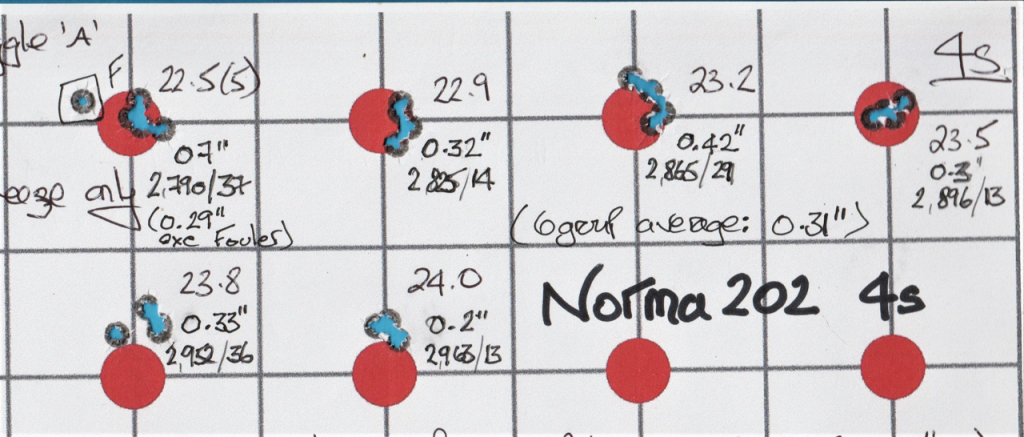

I’ll concentrate on the slower burner of the pair, 202, as it is the better match to H4895. Norma’s 23gn maximum charge for the 77gn Sierra MK at 2.26-inch COAL for the short-freebore 223 Rem SAAMI chamber is a bit above Hodgdon’s H4895 equivalent, but maximum for the latter is slightly constrained by an over-full case. My equivalent top charge to the ‘book max’ is 23.8-24gn 202 after allowing for my much longer freebore chamber and the bullet seated to the 2.4-inch COAL. QL calculated 2,975 fps from a shade under 55,000 psi from 24.0gn, pretty well ideal if it worked out like that. It nearly did with 2,963 fps on a warm (by Diggle standards) summer’s day, only just shy of the prediction, also H4895’s 24gn/2980 fps benchmark. Pressure signs as in hard extraction and primer condition were non-existent and mild respectively, so no worries there. Case-fill was ideal too at just under 100%. Ballistically, we can therefore see that this powder is a close match to the benchmark H4895, but limited to lower loads than H. VarGet despite what burning rate charts might show.

On the paper at 100 yards, the 202-based handloads put up a good show in my Savage PTA based F-Class rifle. The five rounds in the first group fired from a clean barrel spread out to 0.7-inch, but discarding its first barrel-fouling shot more than halves the group size to 0.29-inch, also giving us six four-round groups covering the 1.5gn charge weight range. Their ‘agg’ was 0.31-inches, not the smallest of the test series, but still very respectable. The three highest charges saw groups tighten up, losing the first three’s elevation spreads and finishing on a very nice 0.208” from 24gn. POIs were stable, just rising around a third-MOA for the final pair of charge increments. ES spreads were interesting with an alternating low-high-low pattern over the various 0.2 to 0.4gn charge weight increments, no fewer than three recorded at an excellent 13/14 fps. MVs rose by an average 12.5 fps per tenth grain, not at all abnormal in this combination and no ‘spikes’ appeared. Primer cratering only barely appeared with the top load, that and QL suggesting modest pressures (c. 54,000 psi if the program is believed). To summarise, an excellent result from a powder that had the bonus of a very attractive price when it was available.

Crosswinds!

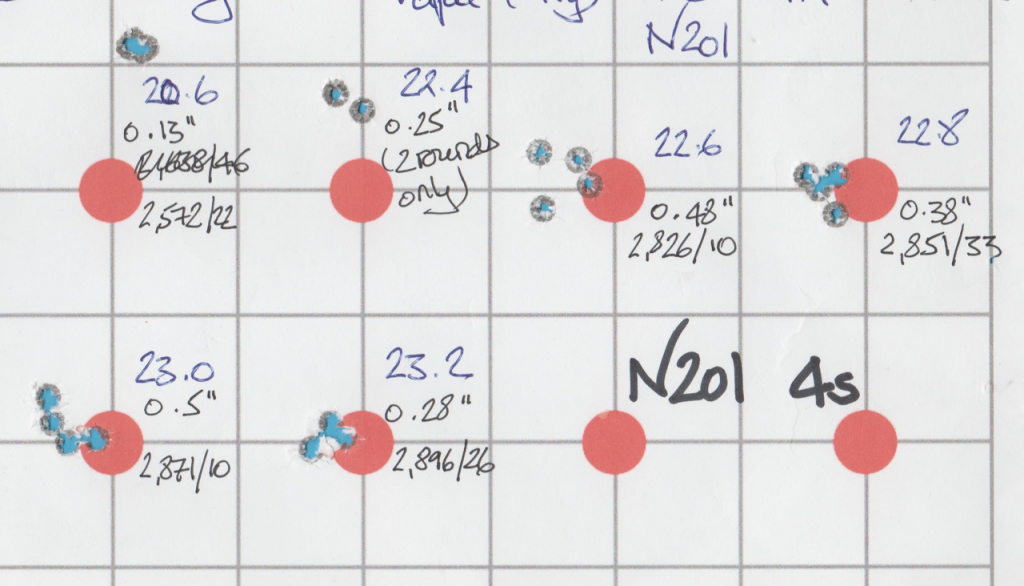

Whilst 202 was a straightforward exercise using charges that were out of the Norma manual increased to allow for my long-freebore chamber and the accompanying longer COAL, 201 needed more consideration. QL v.3.6. gave the same 24gn 55,000 psi maximum charge as 202 in my chamber / cartridge set-up despite this being a faster burner, with only marginal differences to the predicted pressure/MV results. As previously noted, some burn-rate charts show the pair as very close; others not so, so which applied? Why not use Norma’s data again seeing as how I own the company’s reloading manual? The company doesn’t list 201 with the 77gn bullet, just slower-burning 202 and 203-B. Looking at the 69gn Sierra MK, the heaviest bullet that has loads for both grades in its 223 tables, Norma reduces 201’s maximum by 0.7gn compared to 202. In larger cartridges such as 308 Win where there are more dual listings, the ‘201 discount’ increases to just over 2gn on forty-odd grain max values. In the end, I ignored QuickLOAD and simply took my 202 levels knocking off 0.5 to 0.8gn with a new top load of 23.2gn, keeping an eye out during shooting on case/primer condition and my QL N201 incremental charges printout to see if MVs, and therefore underlying pressures, were rising too quickly. My starting load was set low at 20.6gn to ‘calibrate’ it against the QL calculation.

Range-testing proved a bit of a bust thanks to the weather – dry and bright, but with nearly 30 mph winds which bounced off and around the Diggle reservoir retaining wall the range nestles alongside and the steep hillside which forms the backstop to produce violent, constantly reversing crosswinds at the targets. Wind changes moving the bullet was only one of the resulting problems, the first being keeping targets on the frame, the wind getting under the card and ripping it through the staples. Then the aiming mark kept moving while trying to take shots, wind gusts rocking the frame in its holder – and not a chock to be found. Fortunately, the Labradar was unaffected, so collecting MVs wasn’t an issue. This showed that 201 wasn’t vastly different from its slower burning sibling, my top load of 23.2gn producing 2,896 fps, 31 fps higher than from the same weight of 202. Primer cratering appeared at 22.8gn and remained minor up to the 23.2gn top charge suggesting pressures were in the low 50,000s psi, thereby contradicting QL which had calculated a mere 49,000 and a bit psi from 23.2gn. I’m certain that another tenth grain or two increments would have been safe pushing MVs up to 2,910-20 fps, but am equally sure that significant further increases in an attempt to obtain N202 / H4895 speeds would be unwise. Likewise, 77/80gn bullets are probably 201’s limit in the 223 given its burn rate. I should also add that I was using a very old 201 powder lot saved from the marque’s previous appearance in the UK. The flat sided steel can was sealed, but some US reviews of these powders report that 201 has become slightly slower burning in recent years, or to put that the other way round, my lot used in testing was probably ‘quicker’ and would generate slightly higher pressures. Despite the wind-generated problems, a couple of charges still produced small 4-shot groups as can be seen on the target scan. 202’s low-high-low ES pattern reappeared too.

Overall, I reckon that Norma 202 is the closest equivalent to H4895 I’ve tried to date. It is a tragedy that importation was discontinued after a single shipment, but given current propellants manufacturing and distribution in Europe, it may well make no difference anyway, the Scandinavian manufacturers having largely switched to supplying military orders. If it were still being shipped to the US, it becomes an option for H4895 starved handloaders there. (Recent posts on forums such as Accurate Shooter suggest H. VarGet supply has improved but apparently at the expense of H4895.) However, north American correspondents tell me that Norma powders disappeared a year or two back and one received an email from the US importer confirming the company has stopped supplying canister powders for now at least.

Should you find these powders, what can you use them in? 201 is ideally suited to small-case cartridges such as 222 and 223 Rem, especially with light to mid-weight bullets, has uses in 308 Win with lighter bullets (Norma provides data for up to 168gn), then comes into its own again with the big-bore high expansion ratio numbers like the 9.3s, 45-70 and .458 Winchester Magnum. 202 is a good general-purpose medium-fast burning propellant in 223 Rem, 308 Win and many other cartridges as per the benchmark H4895 although it likely won’t see quite as high MVs as the Hodgdon/ADI powder especially with heavier bullets. Neither Norma grade is likely to match H4895 for its tolerance of extreme temperature changes, but that’s not such an issue for us in the British Isles.

Last Viht

I said in an earlier report that I tested six Viht powders in this H4895/VGT category, and here is the final one, N530. This fine-grained ‘high-energy’ (infused nitroglycerin) powder is the fastest burning of the company’s N500 range and was developed for the original 5.56X45mm military cartridge. Viht’s own burn rate table places it as being significantly slower burning than its N130 single-based equivalent, and whilst lying between N133 and N135 is much closer to the latter. Against other makes, its equivalents in this table are Reload Swiss RS40, Ramshot TAC, IMR-4166, and H4895 as well as being just a tad ‘slower’ than Hodgdon H335 which as Olin WC844 was also developed for the original 55gn bulleted 5.56mm M193. Viht provides N530 data for 13 cartridges, a very low number compared to more mainstream grades, and in a couple of these (6.5X55mm and .30-06 Springfield) its use is marginal and limited to very light bullets. So, a relatively minor grade in Viht’s huge range, and as the company freely admits, one that generates modest sales, one of the reasons it has been discontinued. In the 223, there are data for bullets up to 80.5gn including the 77gn SMK I was using, but on Viht’s MVs at least, it is at its best with 40 to 69gn bullets, and even here doesn’t always outperform N133 or 135. It is usable in 308 Win with bullet weights up to 155gn. So, it is on a par with Lovex S060 and even more so Reload Swiss RS40 in its properties and applications.

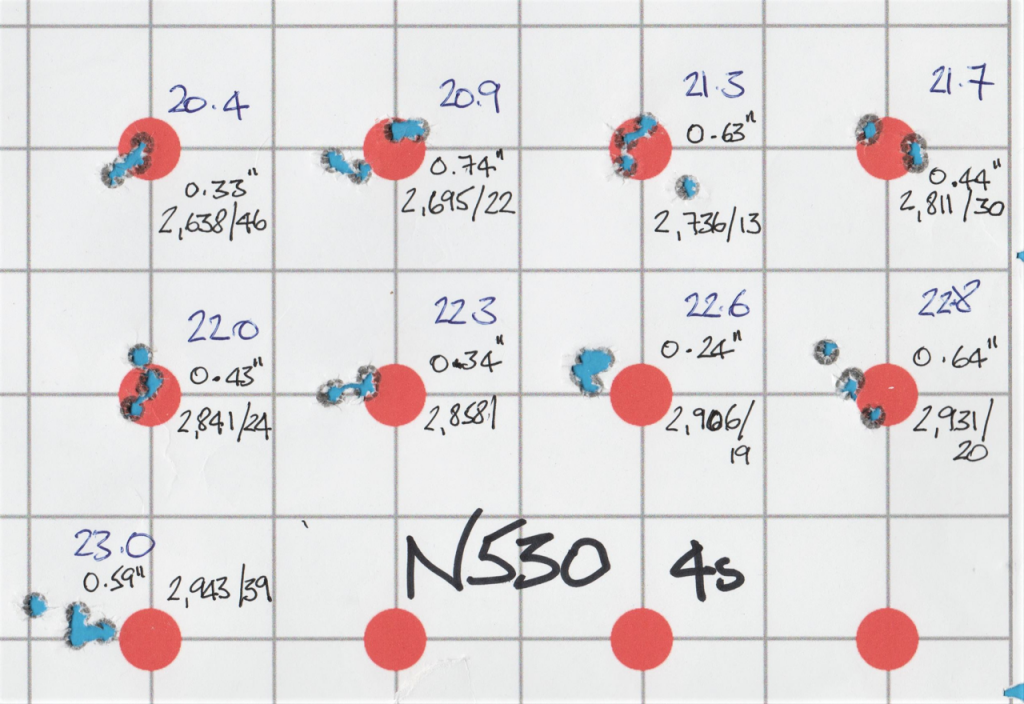

Viht’s maximum charge weight for the 77gn SMK at 2.26-inch COAL and in the short-freebore SAAMI chamber is 22.1gn, making my long-freebore equivalent around 23gn, which I loaded up to. QL v.3.9. calculated 2,959 fps MV from 54,305 psi in my heaviest (30.5gn water capacity) Lapua brass and the result on the range was close at 2,943 fps. With a QL-estimated c.53,000 psi pressure and barely marked primers, I could have increased charges somewhat and no doubt achieved, probably improved on, H4895’s 2,980 fps benchmark performance. So, as with AR-Comp, RS40, S060 and Norma 201, N530 is apparently rather faster burning than H4895 despite what burn-rate charts show.

With those high MVs, I would love to report groups in the ‘ones’ and single-figure ES values, but unfortunately this was not to be. Although the 22.3 and 22.6gn charges produced third and quarter-inch groups respectively, they were exceptions to the near-half to three quarters-inch norm, and with most MV spreads in the 20s and 30s, this was an unexceptional, not to say poor, set of results. In mitigation N530, like Norma 201, was tested on that windy Diggle day with the targets shifting unpredictably, so it is impossible to say which ‘fliers’ were ‘conditions’ and which powder performance. The group shapes make me think the larger examples weren’t all down to the wind, but this may be my prejudice showing as my many attempts over the years to make this powder perform in various cartridges and combinations were rarely successful. (The most recent attempt before these tests was with the little 6.5mm Grendel where it ticked all the boxes in both published data and QL results, but produced mediocre groups and large ES values.) Anyway, as these test batches used the dregs of an ancient bottle, and the powder has been withdrawn, that was perforce its sole outing.

Balls and Spheres

N530 concludes my review of H4895/VarGet extruded alternatives. Next up, but not for a while, I’ll report on the final part of this exercise focussing on Reach-compliant ball or ‘spherical’ powders. ‘Spherical’? That’s what Hodgdon calls the type as the word ‘ball’ in respect of propellants was trademarked by the old Olin Corporation and can only be applied commercially to Winchester brand powders. I have yet to load and range-test any powders in this group in the 223 Savage, so this will take some time. At present, I either have or have been promised eight grades, and there are a couple more possibilities from the USA (recent introductions, one each from Alliant and Winchester) whose arrival here has been promised by the importer, but have yet to appear so far as I can tell. The current breakdown is four from Belgian manufacturer Eurenco P B Clermont marketed under the Ramshot brand; three Czech manufactured Lovex D-076 series grades; a single American (General Dynamics St. Marks) powder, Hodgdon CFE-223. In the interim, I’ve taken a look at the new Winchester StaBALL 6.5 ball-technology powder comparing it to Hodgdon H4350 in 6.5X55SE – an add-on to the H4350 alternatives exercise completed in Reach Out-4 (www.targetshooter.co.uk/?p=3683). There are also a couple of little 223 spin-off tests that I’ll report on.