WINCHESTER StaBALL 6.5 vs HODGDON H4350

The powder availability updates in the Reach-Out series make for a dismal tale, a steady loss of products, Reach-compliant or not. We finally have some good news with the introduction of three new Reach-compliant Winchester ball powders, the ‘StaBALL’ series: 6.5, Match, and HD. The first named is roughly equivalent to the 4350s; ‘Match’ to Hodgdon VarGet; whilst ‘HD’ is a very slow-burner somewhat equivalent to Hodgdon Retumbo. I don’t shoot anything that can use ‘HD’, but the other pair are ‘on’ for testing in my 6.5X55mm and 223 Rem / 308 Win rifles respectively. The ‘6.5’ version was the first to arrive in the UK, therefore range-tested. ‘Match’, which I’ve only just purchased, will follow in a month or two.

Before getting into testing and results, let’s do a bit of background. They’re manufactured by the sole surviving US producer of rifle grade propellants to the civilian market, the former Olin Corporation plant in St. Marks, Florida. This is now a member of the Ordnance and Tactical Systems division of the massive US owned global aerospace and defence company, General Dynamics. St. Marks makes one type of propellant only, ball-powder, or perhaps more accurately that should read as products using ball-powder technology, as they may not in fact end up ball-shaped. Its handloading products are sold under the Winchester, Hodgdon, and Accurate brand names – all of which are now parts of the Hodgdon Powder Co. empire. It also makes Alliant’s ball-type powders including the Power-Pro rifle propellants range.

Hodgdon has a long association with Winchester/Olin as was, and from 1970 the St. Marks facility, then newly built on recovered Florida coastal swampland to replace the original Winchester explosives factory at East Alton, Illinois. All Hodgdon brand ‘Spherical’ grades have been produced by Winchester/Olin and its successors since BL-C(2) back in the 1950s. However, despite being the primary supplier of ball-type propellants to the US handloading market, most of St. Marks’ output goes to ammunition manufacturers for both sporting and military grade products. Reportedly, St. Marks Powder supplies over 95% of the powders used in US military small-arms cartridges, many other military products too such as mortar propellants and artillery initiator charges. The company has a reputation for top-notch R&D, continuous product improvement, and is regarded as a leader in the field.

Ball-technology propellants are made using very different factory processes from those employed in producing extruded / tubular types. Originally developed for Winchester in the 1930s by Dr Fred Olsen, the driver back then was to devise a process that could recycle the large quantities of government military nitrocellulose products that passed their use-by dates each year instead of dumping them at sea. (Think big-gun blue-water navies, the strategic forces of the era, and those propellant bags power-rammed into the chambers of battleships’ and other large warships’ guns behind eight to sixteen-inch calibre shells!) Ingredients, consisting of a combination of reused and freshly made nitrocellulose were part-dissolved in solvents to slurry form, piped around the factory between processes, chopped into little-bittie pieces, agitated in solutions to form balls, and finally ‘cooked’ in large heated stills. Nowadays, there are no longer large quantities of surplus explosives hanging around waiting to be recycled, so the process relies on fresh ingredients. Even so, the start to finish production cycle that takes two weeks for a batch of extruded type powders is compressed to some 40 hours in ball powder production reducing production costs significantly. As processing takes place under water, the risk of fire and explosion is much reduced. Nitroglycerin is usually required to make things work as they should, so nearly all such propellants are double-based including the StaBALL range of products. Despite that, ball powders do not have a reputation for causing enhanced barrel wear, their proponents claiming the opposite, and US Army investigations found no difference in barrel life between extruded single-based and ball powders in rifle calibres.

For more information on St. Marks and some photographs see this Guns & Ammo magazine article by David Emary, Hornady’s retired chief development engineer: www.gunsandammo.com/editorial/ball-powder-st-marks-powder/462658 .

StaBALL = [Temperature] Stable

With competing technologies, there are always pros and cons for their products. Putting production processes and costs to one side, the big plus for ball powders is more accurate metering in charge dispensing, and I’m not talking handloaders’ measures here although that is an important factor to many recreational shooters, rather the industrial scale devices used in ammunition factories. Many military users prefer ball powders as consistent charge weight = consistent gas port pressures = fewer weapons stoppages. The US Army has specified ball powders only for both 7.62 and 5.56mm cartridges ever since the former was adopted in 1954, the exceptions being special-purpose loadings such as the M118LR 7.62mm sniper/match cartridge. Another plus is their high bulk density, so you can pack a lot of powder and energy into small cases such as .223 Rem / 5.56mm.

Historically, ball-powder downsides were its being dirtier-burning (due to a higher percentage of inert constituents); inflexibility (a smaller range of loads and pressures where the powder performs consistently); and being more temperature-affected. Ball-powder technologies have improved enormously over the last 50 years mitigating many issues and have been leaders in some fields such as incorporating anti copper-fouling ingredients, but the temperature issue remained a stumbling block. Field experience in Iraq and Afghanistan was an eye opener for US ground forces in many respects including weapons and ammunition having (and sometimes failing) to cope with a combination of punishingly high peak temperatures and vast seasonal, even daily variations. (Think of the conditions portrayed in the desert counter-sniper scene from The Hurt Locker………..www.youtube.com/watch?v=dxB5M1L2I9s)

This led to intense pressure being put on propellants and ammunition suppliers to come up with improvements. Hence the St. Marks developed and produced Winchester brand ‘StaBALL’ powders, ie ball types that are [temperature] stable, and employing a clever pun on how Americans pronounce the word ‘stable’. Whilst this development is welcomed by many target and sporting shooters, don’t kid yourself that it has come about from our needs – we’re bit players in how powder companies allocate R&D, likewise production/supply priorities, not in the lead as many recreational users think.

Not Just Stability

Whilst Hodgdon Powder settled on the ‘StaBALL’ consumer marketing name emphasising temperature stability, St. Marks chemists use the term ‘Accuflat’ for these propellants. The first half of that compound word suggests a promise of improved consistency in their internal ballistics, which in turn improves potential precision for cartridges using them. There are hints around that they do perform better than earlier generations of ball powders in this respect.

Will we therefore see a broadening of handloaders’ powder choices, specifically for paper-punching and precision applications with these new-generation St. Marks powders? There is earlier-generation ball-powder use in high round-count applications as the type is so well suited to mechanical powder measures on progressive presses, but otherwise sees limited use in precision handloads. Look at the cartridge guides on the accurateshooter.com main site, and you’ll find few ball-powders in the ‘Favourite Recipes’ listings. For instance, the website’s original subject, the 6mm BR, has only one ball powder load in 37 match and varmint load combinations. Yes, I know these guides are long in the tooth, but even so, the preponderance of extruded powders is striking. So, the introduction of Accuflat / StaBALL technology may prove significant, but only time will tell if we’re about to see a genuine game-changing breakthrough here or not. There are non-performance factors too, price and availability.

Not Balls

I mentioned that not all ball-technology powders have round ball-form kernels. Look at StaBALL 6.5 under a magnifying glass and the kernels aren’t spheres, instead flat, rounded disks like miniature coins, so the second syllable in ‘Accuflat’ is apt. Magnified further through the camera macro-lens, many kernels are not quite as round as I first thought, but look remarkably consistent dimensionally – A Very Good Thing in ball-type propellants. When seen against Ramshot Big Game, a Belgian manufactured ball-shape powder, 6.5’s kernels are not only a different shape, but very much larger. They’re still very small however compared to most chopped extruded grades such as similar performance Reload Swiss RS62. (Ignore the two RS62 kernels that have rolled into the right side of the StaBALL heap in the photograph).

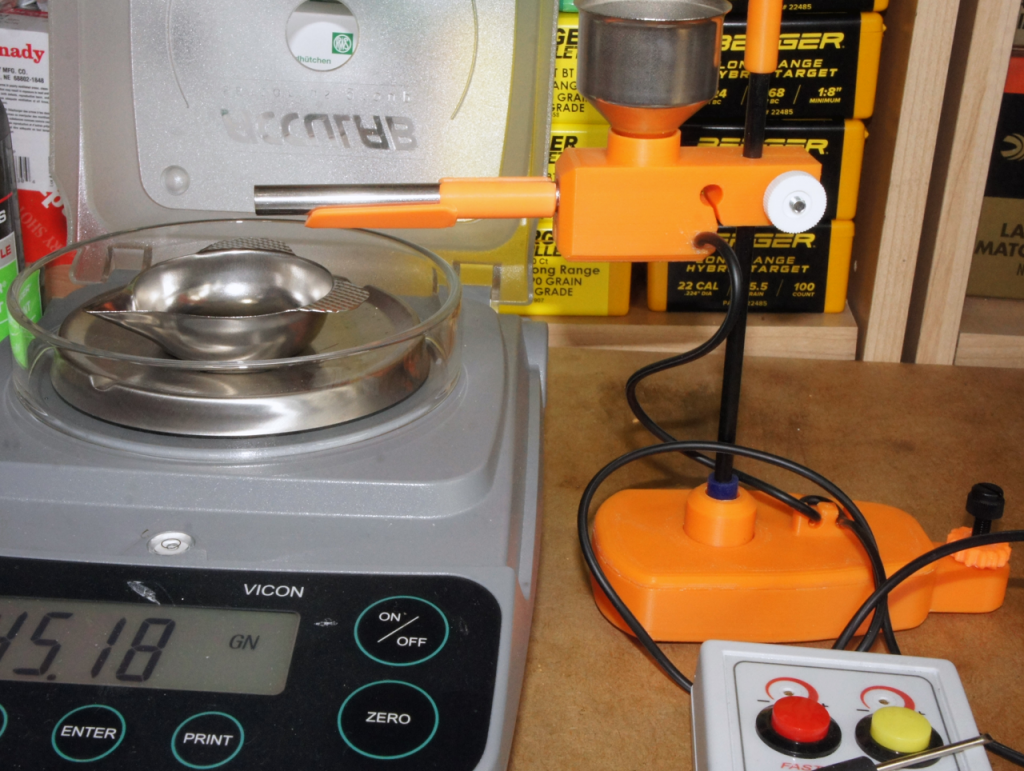

These larger disk-shape kernels are not a downside for me, as I won’t use my RCBS Chargemaster for dispensing Ramshot or Lovex ball-types due to their tendency to bounce out of the scale pan after dropping from the dispensing tube, and revert to my old Hornady Competition BR powder measure for this type. But surely StaBALL grades won’t flow or meter half as well in such devices with their larger, flatter kernels? In 6.5’s case, they meter just fine from both devices (without kernels bouncing out of the Chargemaster pan). Set up to dispense c. 45gn weight, 10 Chargemaster charges had an overall spread of 0.14gn (check-weighed on my Acculab scales). Thirty thrown by the Hornady measure had a larger overall spread of 0.24gn, but I noticed variations reduced as I went along, and the final 15 fell within an astonishing 0.08gn range straight out of the measure.

‘6.5’ in a 6.5

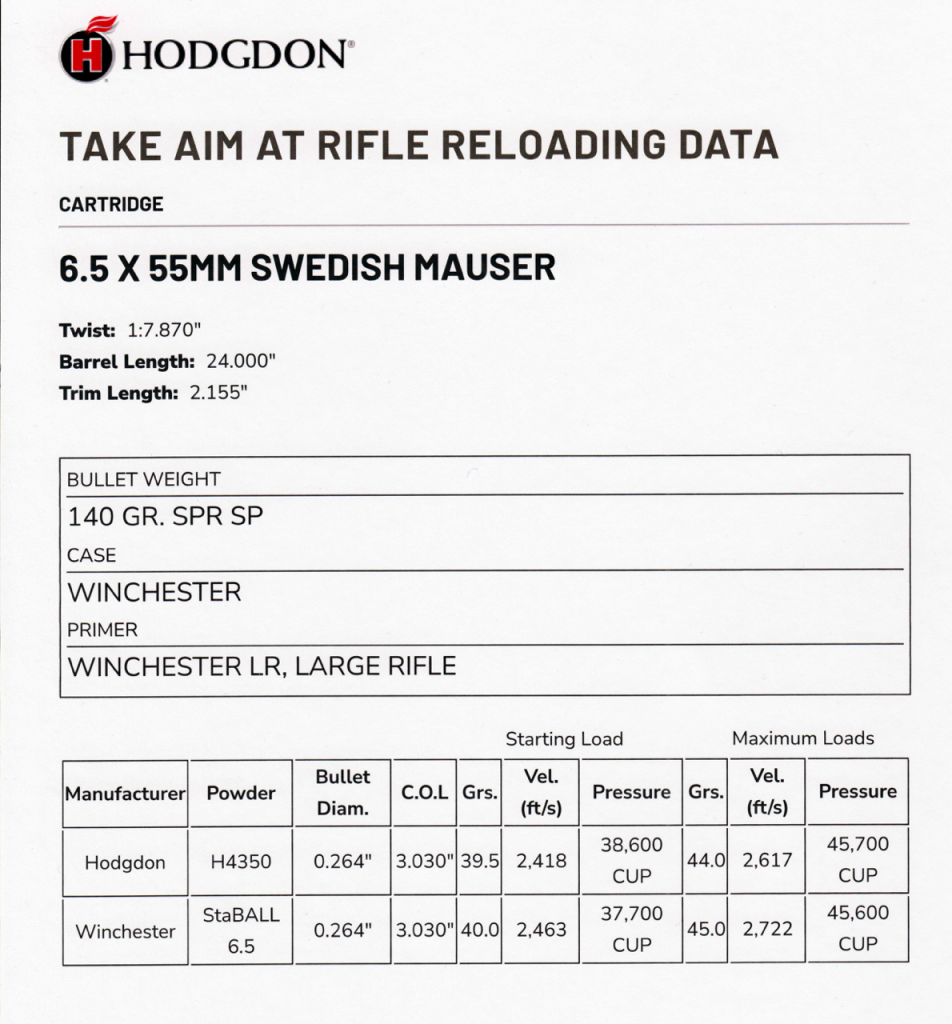

Calling this grade ‘6.5’ is presumably an unsubtle attempt to link it to the 6.5mm Hornady Creedmoor phenomenon. As the ‘go-to’ powder in the Creedmoor is H4350, this suggests the Winchester grade’s internal ballistics behaviour is like that of the Hodgdon wonder-powder. Ideally, I’d have tested ‘6.5’ in the 7mm-08 Savage F-Class rifle used for H4350 alternatives in my Reach-Out reports, but things have moved on. That Savage 12 PTA based rifle was again used, but its 7mm barrel has gone and a 30-inch Bartlein ‘Heavy Palma’ profile tube has replaced it chambered for 6.5X55mm SE. No matter, as the 4350s have long been first choice for Americans handloading the old Nordic design. It did mean my loading up some H4350 powered benchmark rounds from the remainder in the tin used in the original Reach-Out range work. Hodgdon’s online ‘Reloading Center’ facility has loads for both powders in the 6.5X55 with H4350 and ‘6.5’ maximum charges near identical for bullets up to the 140gn Speer SP at which weight the ball type is allowed an extra full grain at 45gn vs H4350’s 44gn for similar pressures (Figure 1).

Burn rate charts show ‘6.5’ as a few steps ‘slower’ than H4350. Interestingly, QuickLOAD’s default value for the Combined Heat of Explosion metric is a modest 3,600 Joules per gram, slightly less energetic than Viht N160, and even more so than N150, never mind the ‘High-Energy’ N500s. Its energy factor is also down against the benchmark H4350 which is rated at 3,760 J/g, not to mention those of most comparable Alliant and Reload Swiss powders. Despite this, Hodgdon claims StaBALL loads can produce significant MV improvements over comparable conventional propellants.

So, to the loading bench. Components were new Norma cases, Winchester WLR primers and the 140gn Berger BT bullet seated to 3.080-inch COAL, plus the two powders of course. Cases were given minimal preparation in the form of running the necks over a Sinclair E26 expander mandrel to true them and produce moderate and consistent neck-tension, also inside-chamfering the case-mouths. The WLR is a primer I hardly ever use, but had a couple of hundred old examples available. Not only is this the primer in Hodgdon’s data, but it has a reputation as a feisty number, and some (but by no means all) ball-technology powders need some extra primer brisance to ignite consistently. (The WLR had scored as the second ‘hottest’ model in terms of 308 Win MVs when I looked at this subject some years ago – www.targetshooter.co.uk/?p=1471)

The 140gn Berger BT ‘Thick Jacket’ bullets used date from a time long ago when the company started to use heavier, stronger jackets for match bullets and original (thin-jacket) versions were respecified as ‘Hunting’ models. This model’s designation had also only just changed from ‘LTB’ to ‘BT’, the former an abbreviation of ‘Length Tolerant Bullet’, ie a true tangent ogive design which is very tolerant of variations in its seating depth / ‘jump’ to the lands. As I didn’t bother to do a proper COAL measurement job in relation to the lands, I adopted 3.080” COAL taken from a manual for a similar bullet and which saw the bullet-shank seated to just over a calibre’s depth in the old Scandi 6.5’s long neck. A later check with a Hornady COAL gauge showed that this seating depth gave the bullet a LOT of jump, but with this design being so jump-tolerant I wasn’t perturbed. My rifle has the standard 6.5X55 chamber which provides a truly vast amount of ‘freebore’.

H4350 was dispensed by an RCBS Chargemaster 1500 and StaBALL by my elderly Hornady L-N-L Competition BR powder measure. Both sets’ charges were individually check-weighed on a set of Acculab electronic scales and adjusted if necessary to be within a very small variation range with the assistance of a Targetmaster Vibro Trickler. (Review to follow, but if you want to learn more now about this device, see this short video from its maker, Allan Edwards: https://www.youtube.com/watch?v=JS1VSKTQxUM.) H4350 produced fill-ratios in the low 90%s, StaBALL rather less running in the high 80s with Hodgdon’s maximum 6.5X55 Swedish Mauser charges, so will be about perfect in smaller Creedmoor and 260 cases. Bullets were seated on a Forster Co-Ax press utilising the excellent micrometer-adjuster Forster BR Ultra seater die with all resulting cartridges seeing case-head to ogive measurements within a 0.002” range.

On the Paper

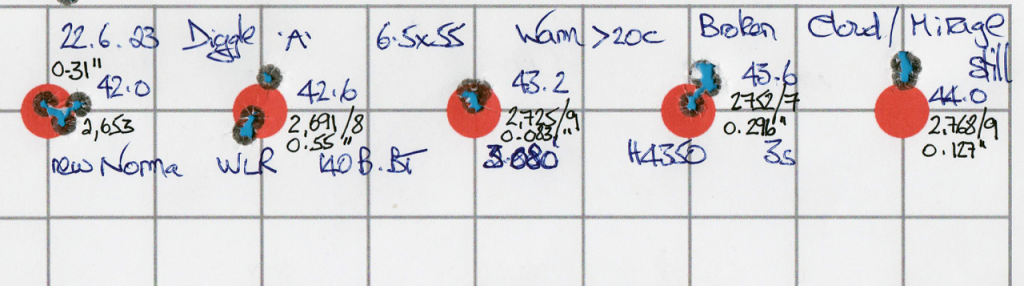

Finally, off to Diggle’s bench-equipped 100-yard ‘A’ range to test both sets and measure MVs on a Labradar chronograph. Conditions were excellent with good light, hardly any wind, and although warm, only occasional light mirage. First to go downrange were five H4350 3-round batches culminating in the recommended 44gn maximum load. This produced 2,768 fps on the Labradar from my 30-inch Bartlein, 150 fps above that achieved in Hodgdon’s 24-inch test barrel, and certainly in the right ballpark. Groups were excellent with four out of the five charge weights putting the 140gn Bergers into a third inch or less, two bracketing 0.1-inch. Only three-round groups, but still extremely promising. Then there were the MV spreads – after the first ‘fouler’ group in a clean barrel, all four in single figures spanning 7 to 9 fps. Altogether, an excellent performance over a 2gn charge weight range, and displaying the flexibility that makes this powder missed by so many British competition shooters. (Also, without getting into the great, sometimes intemperate, 6.5mm cartridge debate, just blow a raspberry at the next range-house know-all who tells you the 130 year old 6.5X55 is ‘inferior’ to modern designs).

StaBALL 6.5 had seven batches whose charges covered the 3gn between 42 and 45gn, the first (5-rounds) used to sight-in, foul the bore, and check for pressure signs. The other six three-round batches covering 43.2 to 45gn were fired on the test target and saw MVs increase by just under 100 fps to 2,761 fps for the top load. Therefore, almost the same MV from the top charges for the two powders, but StaBALL needing an extra grain weight to get there. This suggests it is indeed slightly slower burning than H4350. QuickLOAD reckons those MVs require similar pressures from the two powders – c. 49,150 psi from 44gn H4350 and 49,800 psi from 45gn ‘6.5’. Groups were good, albeit generally not quite as small as H4350’s, everything below the half-inch and one exceptional single-hole result of 0.052-inch (centre to centre) from 44gn / 2,698 fps. Ah! Ha! You say – But, surely that’s the largest group of the series with that low/right ‘flier’. I must confess to having had a senior moment here as having paused shooting for a couple of minutes, I confused myself into thinking this was shot #1 of the succeeding batch, when it was actually the third and final shot of the previous trio from 43.6gn. Luckily for me it was a ‘flier’ moving it well away from the other three shots, and being parked neatly against the edge of the aiming mark and smack on the horizontal gridline, it was easy to mark up where it would have fallen in its proper group.

Excellent! Two very different powders, but producing similar MVs, pressures, and results with the new Winchester grade apparently just a little slower burning, in 6.5X55 anyway. I was impressed by 6.5’s consistency across its half dozen charges – far better than might be expected from an older generation ball-type, especially given Hodgdon’s modest ‘Swedish Mauser’ loads, pressures and MVs. But, (there’s always a ‘BUT’ isn’t there?), two things didn’t turn out so well for the newcomer. First, Hodgdon’s 6.5X55mm data give the 45gn StaBALL load 105 fps higher MV than H4350’s 44gn with the 140gn Speer SP bullet, whilst my results with the 140gn Berger saw it produce seven fps less – that is a huge discrepancy from Hodgdon’s results, important too in that the company is making a big marketing thing out of the new StaBALL range giving higher MVs than conventional powders! Then, while the StaBALL grade gave a couple of charge weights decent MV spreads of 9 and 16 fps, the other four were mostly consistent in the mid-30s with the lowest charge weight batch on the paper (43.2gn) way up at 51 fps compared to wall to wall single-figure H4350 values.

At least some of our retailers have apparently bought into Hodgdon’s PR waffle as a handloading supplier sent me a gushing email announcing the new powder including these words:

Velocity levels obtainable, depending on the cartridge, are 30-200 fps greater than other propellants in its class. Stability, Precision and Speed, says Winchester StaBALL 6.5 is the “Best of the Best”!

Price Confusion

I said earlier that the non-performance factors of price and availability are going to be important for this new Winchester range. The latter appears to be good so far for ‘6.5’ and ‘Match’ versions, but there have been mixed price signals. The UK importer initially announced that RRPs would be £65 for ‘6.5’ and £70 for the other two. Those are per imperial pound (454g) weight! Convert them to kilogram prices and they become £143 and £154 respectively compared to Vihtavuori powders priced in the shops at £105-120 depending on where you buy. So, either some people setting UK prices think these StaBALLs are such superior products they justify a 40% premium, or they (mistakenly) believe that the powder shortage is so dire that people will pay any price for what are, as yet, unknown products.

What are retail outlets actually advertising them at on either side of the Atlantic? Over the pond in the USA, StaBALL prices are set at a significant discount to the Hodgdon extruded ‘Extreme’ range, in line with Americans’ usual price expectations for the lower production cost, domestically produced St. Marks’ powders. The UK supplier who sent me the ‘gushing’ email initially showed ‘6.5’ at £65 per 1lb tin in the release and on its website, but has since updated the latter with a line through the original price and £46.20 substituted. (A near 30% reduction on a brand-new premium product in its first weeks on sale! Really?) ‘Match’ is still shown at £70 by this outfit, but they don’t have that grade in stock anyway. Other retailers’ websites I’ve looked at – who do have the more expensive ‘Match’ in stock – are quoting £50-58 and I shelled out a little below the bottom end of that range to Fox Firearms when I bought my tin a couple of weeks ago. The importer’s retail website? It still shows ‘6.5’ at £65 / lb, and weeks after ‘Match’ appeared in the shops, ‘6.5’ is still the only grade of the three even listed!

Nil Desperandum

Returning to my StaBALL 6.5 MVs and relatively large ES values in the 6.5X55, I’m not unduly concerned. I said in my summary of ball-type powders’ characteristics that they are traditionally less flexible than equivalent extruded types. By that I mean they often need relatively heavy loads / high pressures to produce consistent results. 6.5X55 with American loads data may not be the ideal test vehicle with its US SAAMI MAP limited to 46,000 CUP. The European CIP equivalent for the SE / SKAN versions for modern rifles is 380 MPa (55,110 psi), and its heavier charges / extra pressure should give MVs a significant additional hike as well as reducing ES sizes. (Note the downwards trend in my recorded ES figures as estimated pressures rise from 43.2gn’s 43,000 psi to the top charge’s 49,000 odd.) 6.5X47 Lapua, 260 Rem, the Creedmoors, 270 Win, 7mm-08 Rem and other recommended applications all run yet higher pressures at or over 60,000 psi, and should be still better matched to the powder.

As it is, my groups were still good with these modest loads and pressures, and in a different (better) class than those obtained with earlier generation ball powders in 7mm-08. (Reach-Out 4: www.targetshooter.co.uk/?p=3683). It also burned cleanly in my loads / rifle chamber, so this was a most satisfactory first outing. However, I just cannot see where Hodgdon’s extra MV over H4350 and similar powders is supposed to come from with this being a modest-energy propellant. I can only see higher velocities arising when StaBALL’s higher bulk density allows a heavier powder charge in capacity-constrained cases over equivalent extruded grades such as H4350 before severe load compression occurs. In this way StaBALL 6.5 might allow heavier charges and higher performance in the 260, 7mm-08 Rem, even 6.5 Creedmoor, especially when loading heavier/longer lead-core bullets, even more so all-copper deer bullets at magazine COALs.

Next up will be the ‘quicker’ StaBALL Match which is promoted as a VarGet alternative, and appears to be acquiring a mystique amongst those who’ve never seen, let alone loaded and used the powder. I have serious concerns that the StaBALLs, ‘Match’ in particular, are being over-hyped before anyone gets much field or range experience with them. A British Facebook shooting group member recently mentioned ‘the new Reach-compliant VarGet’, which no matter how StaBALL Match ultimately performs, cannot and definitely will not ever conform to that description! Anyway, I’ll test it in my long-throat heavy-barrel 223 F-Class rifle for which I have VarGet benchmark performance, then at a rather later date look at it in 308 Win matching it against an equivalent single-based, Reach-compliant extruded powder, either Viht N140 or Lovex S062.