WARNING

The load data contained on this site is intended for use with specific rifles and components. Other manufacturers’ equipment will not produce equivalent pressures or velocities. Data contained herein is therefore for the purpose of comparing loads and results against the Reach-ban benchmark grades only, and are not intended for use by individuals – even those who are familiar with correct and safe handloading practices and procedures.

Target Shooter has not set out to produce reloading data but rather to offer alternatives to powders now unavailable due to REACH controls and it is up to the reader to interpret this data to suit his or her requirements and thus no responsibility is assumed in the use of this data. The information is to be used at the sole discretion of the user and the user assumes all risk.

Hodgdon H4895 and VarGet Alternatives – Part 2

Let’s make a start on reporting results. But first, a bit of scene setting on the bits and pieces. The rifle used is another Savage 12 PTA single-shot based job, this time in a McRees Precision chassis stock. Both date from around 13 years ago as imports from the USA. Neither the Savage PTA action’s then bargain price nor McRees stocks’ availability at any price survived for long in the UK, so these choices turned out to be short-lived opportunities. As originally built, it proved to be an effective, if rather heavy, long-range F/TR competition rifle shooting the Berger 90gn VLD from an exceptionally long-throat chamber in a 31-inch True-Flite barrel. (That situation no longer applies in higher level F/TR given substantial 308 Win performance improvements over recent years, not matched in 223).

Nevertheless, I still really enjoy shooting the little 223 Rem, so when re-barreling was needed I had a Benchmark 30-inch F-Class / Heavy Varmint profile 7-twist barrel put on ignoring F/TR weight limits, possibly giving me the UK’s only 223 Rem F-Open rifle. Not that I intend using it in long-range competition, just short-distance outings in calm conditions. Its chamber is also long-throated, but not nearly as much as the original in keeping with the rifle’s new role and my intention to mainly shoot 80s through it. With the Reach-alternatives exercise coinciding with the rifle coming back online, I went straight into shooting 77gn SMK test loads and have yet to work up 80gn match bullet combinations, so it’s too early to know if this strategy works. When Stuart Anselm of GS Precision Engineering did the barrel work, he also fitted one of his barrel tuners on the muzzle for future experimentation. It was screwed into the half-way position on its threads, locked into place, and left untouched throughout this exercise.

Brass, Bullets and Dies

Ammunition components and loading practices wise, all test rounds have used Lapua cases starting out as new from my two ‘blue box’ lots with 30.5-30.7gn water capacities depending on lot. Primers are elderly Russian (Murom) manufactured PMC-brand SR Magnums. These primers reportedly employed explosive pellets identical to those used in the contemporary mild copper-colour PMC SR primer, but with thicker/harder cups to handle high (5.56) pressures. Recently manufactured Murom SR/SRM primers are said to be more aggressive, a response to feedback from US XTC competitors. Side by side primer tests in the Savage show that this (PMC SRM) model often doesn’t give the best results, but the ‘hard’ cup was desirable given that some test loads might produce higher than expected pressures. It was important to stick to one model too across the large number of test rounds. (In fact, they’re all from a single production lot).

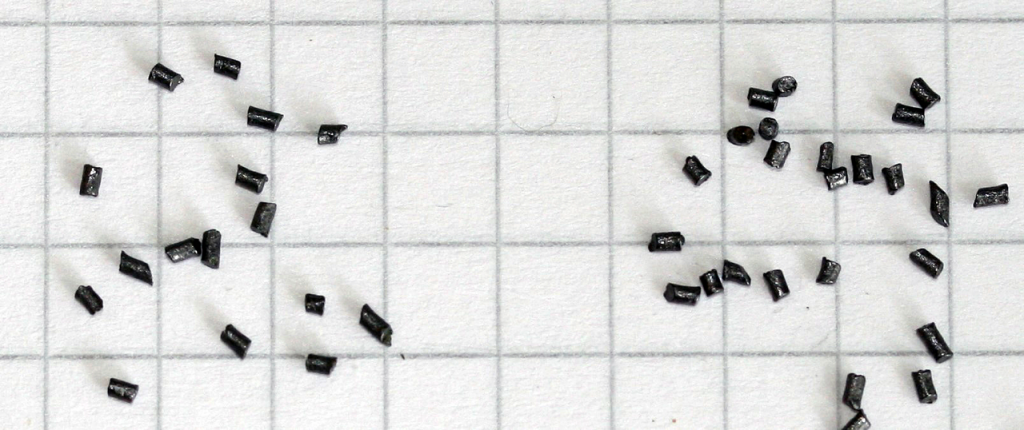

As already stated, the very chamber/barrel tolerant 77gn Sierra MK has been employed, seated at around 20-thou’ off the lands. All bullets were BTO-checked with a Hornady L-N-L comparator and .22 insert and batched to within 0.001” before loading. Actually, they have been very good indeed in this respect out of the box and this is likely gilding the lily. The CBTO was kept to +/- 0.001” with the exception of cartridges loaded with a single powder which I’ll cover in the next part of this series. All extruded powder test loads had individual charges dispensed by an RCBS Charge Master machine, then check-weighed on a set of electronic Acculab scales and adjusted if necessary to fall within +/- 0.04gn, (usually less), that is typically within a range of at most, four extruded powder kernels’ weight. (This was held to within 0.02gn overall variance, ie a single Alliant Re15 powder kernel, in my long-distance 90gn-bullet F/TR match loads of a decade ago – an onerous, time-consuming job).

Four conventional 7/8X14” dies mounted in a Forster Co-Ax press have been used throughout: Lee Universal Decapper (followed by case and primer pocket cleaning); Forster Bushing-Bump sizer die without a bushing installed; Lee Collet neck-sizer; Forster BR Ultra seater die that comes with a micrometer top graduated in single thou’ COAL changes. Without a bushing, the Forster sizer only touches the case-shoulder, the die set in the press to ‘bump’ it back by a thou’. Necks are then sized separately with the Lee Collet (LCD). As the Forster ‘Bump’ die only needs the slightest trace of lube on the case-shoulder, and the LCD none at all on the neck, this is a quick and clean sizing operation. You might wonder about the absence of any case-body sizing. I’ve found in both 223 and 308 that when fired in minimum SAAMI gunsmith cut chambers, this action isn’t needed and sizing the shoulder alone gives easy case chambering and extraction over multiple firings even with ‘warm’ loads. (Not to forget excellent results on the target too.) The LCD is used by many American and Canadian 223 TR and F/TR shooters for giving very concentric and consistent results, but is usually employed in conjunction with a full-length sizing ‘body die’. Note that whilst my method works well in match chambers, full-length body sizing may produce better results in factory rifles.

Tests and Reports

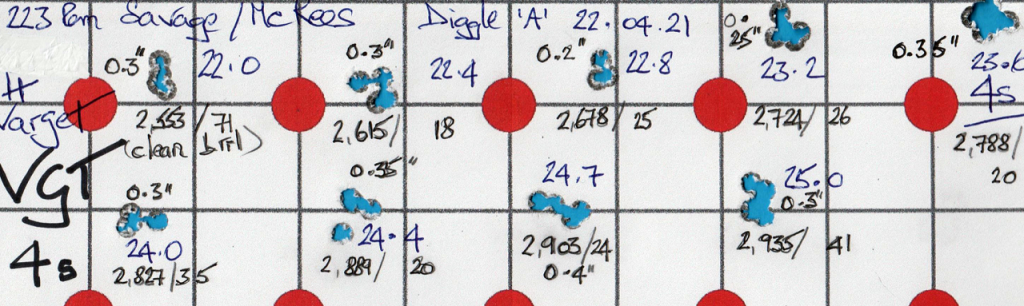

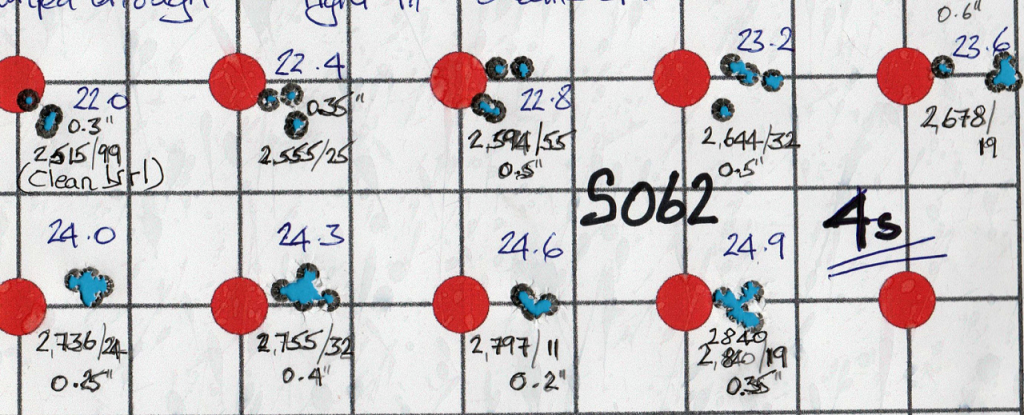

As with the 7mm-08 H4350-alternatives exercise, testing was carried out over 100 yards from a full benchrest set-up, MVs and spreads measured on a Labradar chronograph. Targets are the free downloaded half-inch diameter red-spots on an inch-square matrix from Targets.com, printed on heavy card to give ‘cleaner’ bullet-holes and mounted landscape wise on the target frame to allow POI elevation changes to show up. Whilst 7mm-08/H4350 testing had necessitated three-round groups, the lighter recoiling and less barrel-heating 223 allowed an increase to four. The ‘cunning plan’ had been for six charge weights per powder, which with an extra round in the first batch amounts to 25 rounds, or two powders per 50-count MTM box. Like many ‘cunning plans’, this more often than not went by the board for various reasons and many powders have seen a much higher round count, often with a second ‘follow-up’ string after the initial loadings were fired and results evaluated. These ‘follow-up’ groups were often of five-rounds, especially if the initial groups had shown promise and/or I was interested in seeing what the powder could achieve in both precision and velocities.

Reports will be as per the 7mm-08/H4350 series using target scans, but with extruded and ball powders loaded, fired and reported on as two distinct groups starting with the extruded (tubular) grades, and within that VarGet alternatives first, followed by H4895. With 20 extruded powder reports including two each for the Reach-banned benchmark H4895/VGT, that’s four separate reports in all (including this one). Why two each for the Hodgdon pair? They were first shot on a nearly new and barely run-in barrel. It’s not unknown for pressures and MVs to rise after 100-200 rounds down stainless match barrels, so I’ll retest a few rounds with the maximum charge I used initially with each soon, hopefully in time for the second report on each grade’s alternatives.

Onwards and Upwards

If I were being pedantic (Me? Never!) I’d say ‘Onwards and Downwards’ as we usually talk about bullets going ‘downrange’. Anyway ……., as promised, let’s kick off with Varget. Incidentally, I should add that the late spring to early winter of 2021 saw the longest continuous dry and calm period I can remember giving excellent testing conditions, bar noticeable mirage in some sessions. My range notes are peppered with ‘Light winds only’ or even ‘Still conditions’ – very unusual indeed for Diggle. Only the last couple of (now winter) sessions saw the return of more typical Pennines weather, ie wind, rain/drizzle, hill fog. Ambient temperatures also fell within a generally modest 10-deg C range with the sole exception of cold morning starts during April/May’s late frosts, otherwise insufficient variation to produce significant pressure effects in temperature-affected powders.

Hodgdon VarGet

Our first benchmark was shot after some 65 Reload Swiss RS50 powered running -in rounds, so the barrel was still very new, (hence my desire to recheck the maximum load’s MVs). Hodgdon’s max charge weight with this bullet in roomier R-P brass (but in the short-throat SAAMI chamber) is a compressed 23.7gn, so you might think my 25.0gn top load in lower capacity Lapua cases is incautious not to say downright dangerous given what I said in H4895/Varget Pt.1 about small changes in charge weights having disproportionate pressure effects in this little cartridge. On the rough and ready formula previously mentioned, 1.3gn extra powder would be expected to increase pressures by over 8,000 psi. Three things though said otherwise – other manuals showing higher charges of the powder up to 25gn even in the SAAMI chamber; my chamber’s longer throat and 2.400” COAL; the cushion of an extra 7,000 psi allowed by CIP for the cartridge. (Nevertheless, my objective was to more or less limit my top charges to producing around an estimated 55,000 psi, the US SAAMI ceiling) for all powders tried. A smidgeon of QL modelling showed that the longer chamber freebore needs 0.8/0.9gn more powder across a good selection of suitable powder grades to achieve the same Pmax level as would be produced in the SAAMI-specification chambers used by the powder and bullet companies.

QuickLOAD (QL) calculated 2,982 fps MV at 55,081 psi Pmax from 25gn Varget in my set-up with 30.7gn water capacity brass. In the event, actual MVs in the near-new barrel were down on those forecast at 2,935 fps on the Labradar. That’s equivalent to 24.6gn in the QL model, not really so far out. As can be seen from the target scan, I didn’t limit the test to six groups, trying nine charge weights in total starting from a fairly low 22gn and working up mostly in 0.4gn, then 0.3gn steps. The low start / large range were simple prudence with a new barrel, chamber and components combinations. Note the nearly 400 fps MV difference over 3gn of powder, averaging 127 fps per grain. As previously noted, the 223 handloader needs to think in one or two tenth grain effects, especially as peak pressure loadings are approached – and this is with a relatively slow-burning powder for the application with some higher energy / faster-burners producing larger changes than Varget’s 13 fps per 0.1gn.

For a first outing with a new set-up, results were good, all nine groups easily under the half-inch; six under third-inch. Given slightly better still results from the H4895 benchmark string shot immediately afterwards in the same range-session, expectations increased so that I now regard any combination that doesn’t produce a sub quarter-inch 4-round group as ‘a bit disappointing’! MV spreads weren’t so hot though covering a range of 18-41 fps (excluding the first group’s larger value from fouling a clean barrel). This is a perennial issue with the cartridge and I’ll say now that you shouldn’t expect spreads regarded as normal in 308 Winchester match loads, never mind 6BR, even with carefully assembled ammunition and quality brass. (Actually, many casual or tyro 223 Rem handloaders would regard these figures, most in the low to mid 20s, as excellent.) With the 5.5-inch drop-tube Forster powder funnel and a slow, angled pour, 25gn Varget gave ~100% case-fill with the 77 SMK seated out for the custom chamber. I say this about loading so many cartridges that repetition becomes a trifle boring, but this or another longer drop-tube design is a near essential accessory. (Many other extruded powders tried in this test series produced moderately to heavily compressed charges with their heavier charges even using the Forster tool).

‘Snail’ Mk3

My first Varget alternative powder is one I’m very fond of in this (Varget alternative) role, yet is probably the least well known and appreciated fast to medium burn-speed propellant in this country – Lovex S062 (SW ‘Precision’ in the US). This is a no-frills single-based, short-cut, tubular powder that does everything it says on the tin. It was originally marketed here as a ‘European 4064’ and it lives up to that claim by emulating that supremely flexible good-performing US number closely with a huge number of applications, similar charge weights, and usually very good performance – all without the IMR original’s drawback of over-long kernels. My impression from previous 308 Win use is that its charges and performance are close to those of Varget, but I hadn’t used it before in the ‘mouse cartridge’ and found its ‘effective burn-rate’ slower in this little case.

Again, I loaded up nine batches starting at 22gn and stopped just a tenth of a grain short of my Varget maximum, ie 24.9gn. QuickLOAD v.3.6 predicted 2,994 fps at 55,279 psi in my long-throat chamber with 30.7gn water capacity brass, close to its 25gn Varget prediction. On the range the Labradar said otherwise, 2,840 fps recorded at that charge level, equivalent to 23.4gn / 45,709 psi in the model. Yet again we have a Lovex S-grade that appears to be slower burning than it should be from the manufacturer’s ‘closed bomb’ results and values – which mirrors similar findings with S065 and even more so S070 in the 7mm-08 tests.

Three four-round and a single two-round lot were subsequently loaded and fired taking charges from 25.2 to 26gn. S062’s equivalent charge weight to Varget’s 25gn/2,935 fps MV would be c.25.6gn in my barrel, so in this cartridge at any rate, the Czech powder appears to be significantly slower burning. 2,979 fps as produced by my new maximum charge of 26gn should run at a modest 54,000 psi according to QL. However, charges above 25gn were heavily into compressed-load territory, so this is a significant constraint on the powder’s use in 223, less so in 308. ES values had a wider range than from Varget running from 3 to 55 fps excluding initial ‘fouler’ groups, and although I achieved my 0.2gn group expectation and one or two others around the quarter-inch, groups were generally larger too. I suspect that since 77gn bullets prefer a slightly faster burner in the 223, S062’s slower than Varget rate may be the cause. 24.6gn produced a nice tight little elevation-free group and only 11 fps ES, and this charge weight was used in a couple of simple little tests that I’ll report on later. Although showing promise, that charge weight’s average MV just below 2,800 fps is much too slow for the bullet weight from a 30-inch barrel, long-freebore chamber set-up, 3,000 fps plus or minus 50 fps being the desired range. So, yet again, the Lovex contender has produced the metaphorical snail of the series, even if that may not apply to such a degree in larger cartridges.

Swiss Contenders

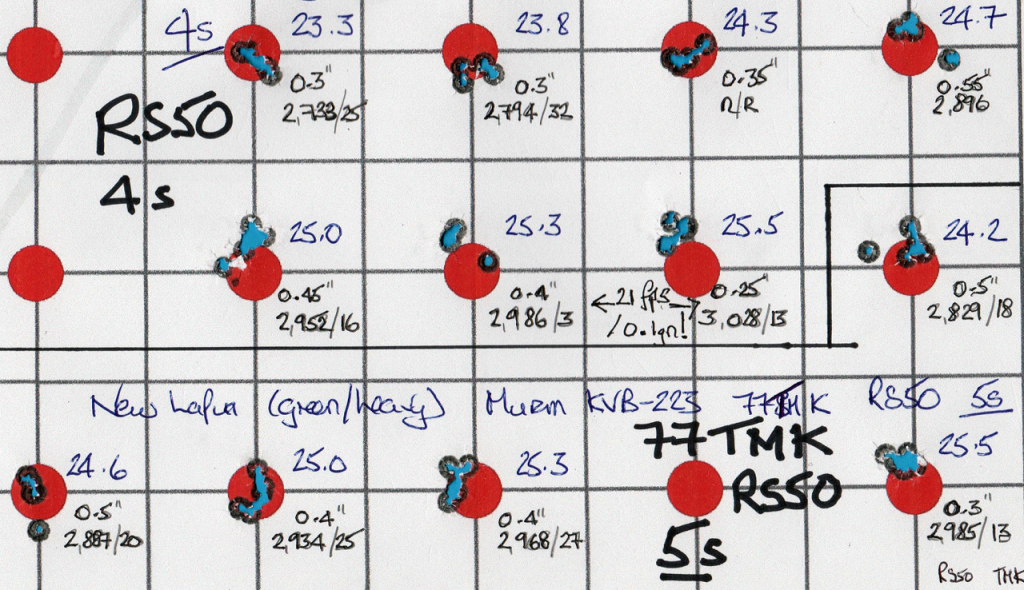

Let’s move onto the two Swiss propellants in this category, Reload Swiss RS50 and 52. Whilst the pair have similar nominal burning rates, they’re very different powders. RS50 is an excellent vice-free single-based short-cut propellant very much in the Viht N140 and similar powders class.

By vice-free, I don’t mean you can never get into trouble with it, there being no such propellant in existence, rather that when used in suitable applications with sensible loads, MVs rise in a nice linear manner until mild pressure signs start to appear. It’s capable of producing excellent MVs in 223 with heavy bullets and 308 across most bullet weights, often with exceptional precision. RS52 is a ‘high-energy’ grade, (ie starts out single-based in the production process with nitro-glycerine infused into the kernels at a later stage), and is a recipient of Nitrochemie’s patented ‘EI’ technology that infuses the ‘deterrent’ chemicals into the kernels giving a longer lasting effect than simple surface coating. Think RS60 / Alliant Re17, but with a similar burn rate to H4895/Varget. It can give startling performance, but if you overdo charges, it can turn round and inflict a nasty bite without much prior warning. In larger cartridges such as 308 Win, I’ve found it to be very close to Varget vis a vis charges but, giving higher velocities. Reload Swiss UK describes the RS50/52 pair as ‘universal 308 Win powders’, a view I’d concur with.

RS has 223 Rem 77gn SMK loads for three powders on its UK website (www.propellants.co.uk then go to ‘Powders Chart Access’ and in its menu, ‘Reloading Data’): the faster burning RS40 (which I’ll cover as an H4895 alternative); RS50 and 52. These are for the bullet seated to 2.26” COAL and presumably in the standard 223 Rem short-freebore chamber. With Norma cases and RWS primers, maximum charges are 24.4gn (RS50) and 24.1gn (RS52). Remember, my long freebore chamber lowers pressures and I need another 0.8gn or thereabouts to produce the same levels. But, the table’s MVs seemed low for a 600mm test barrel at under 2,800 fps (2,713 and 2,789 fps respectively), especially as RS40’s maximum produced 2,890 fps in the same set-up. No load was indicated as compressed, but RS data include pressures and the three powders’ Pmax values are reported as 58,653, 48,965, and 49,936 psi (RS40, 50, 52 respectively). So, firstly Nitrochemie is apparently working to the higher CIP 223 / NATO 5.56mm pressure ceiling as those RS40 pressures are significantly higher than those quoted by US powder companies working to SAAMI. Conversely, RS50 and 52’s sub-50,000 psi pressures suggest that it is case capacity at the 2.26” COAL, not pressure, that dictates their top ‘book’ charges in the 223.

What does QL say on the matter? With a 24-inch barrel, my Lapua brass’s capacity and in the short SAAMI chamber with 2.26” COAL, the program calculates just over 100% case-fill with Reload Swiss’s maximum charges and producing pressures close to those shown in the company data, ie sub-optimal levels around 50,000 psi. With my longer chamber freebore and 2.4-inch COAL, QL increases both powders’ maximum charges to around 26gn, the pair then seeing mildly compressed loads and predicted Pmax values of 55-56,000 psi producing MVs of 2,961 fps for RS50 and 3,072 fps for its ‘hotter’ high-energy EI sibling in my rifle’s 30-inch barrel. In practice, I limited RS50 to a top load of 25.5gn which actually produced a very creditable 3,028 fps, but had to be running at far higher pressures than QL calculated to get there, somewhere around 58,000 psi, and that despite the significant half-grain charge reduction.

I didn’t model RS52 in QL before deciding on charge weights as I know from previous experience that the program seriously overstates usable charge weights and thereby underestimates pressures / MVs, even more so than with RS50. My usual practice is to adopt Varget charges and proceed with extreme caution, so as with Varget, 25gn was my chosen top load with this grade. It produced an impressive 3,066 fps, accompanied however by the much less desirable appearance of pressure signs on the primers, fairly heavy ones at that. Not yet over-pressure in my reading of them, but not a lot short of being there! If I were to continue with this combination, I’d limit RS52’s charges to 24.5gn in this chamber. So, in my rifle, RS50 turned out to be close to Varget, whilst RS52 appeared to be the faster-burner of the RS pair – significantly so – needing charges to be lower than either RS50’s or Varget’s and acting more like H4895. It appears that the move to the little 223 has effected a change in RS52’s characteristics and results. This is an interesting, not to say instructive finding, but hardly astonishing. Many powders don’t retain the same characteristics across a range of different size cartridges and that’s before we get into possible behavioural changes created by Nitrochemie’s ‘EI’ technology.

So far as performance goes, both RS powders did well on MVs, also on velocity spreads. Groups were a tad disappointing. Neither produced the by now expected 0.2-inch group, one or two quarter-inchers as good as it got despite excellent testing conditions. Both had a tendency to split groups with three shots in a tight pattern plus one out at either 11 or 5 o’-clock positions, as in 24.1 and 24.8gn RS52. With RS50, I also loaded 25 rounds with Sierra’s acetyl tipped 77gn TMK variant, a bullet which meplat aside has the same shape as the antediluvian HPBT MatchKing. There were two reasons behind this extra test, the first being the desire to try this newer more expensive model to see how it performs; secondly because rival company Viht’s data gives this version significantly higher maximum charges over the old MK for many of its powders, a 0.8gn increase with N140 for instance. With the same body-form, crucially the same 0.370” shank length, pressures for the pair should be pretty well the same unless the TMK uses a thinner, softer jacket and/or less hard lead alloy core. Or is this just another of those common loads data tables’ quirks, maybe a result of the use of different pressure testing barrels by the powder company given a long gap between tests for this pair of bullets? In my rifle, the TMK did behave slightly differently giving MVs 43 fps down on the MK with the 25.5gn RS50 maximum, but that’s equivalent to around 0.3gn worth of this powder.

If It Looks like a Duck ….

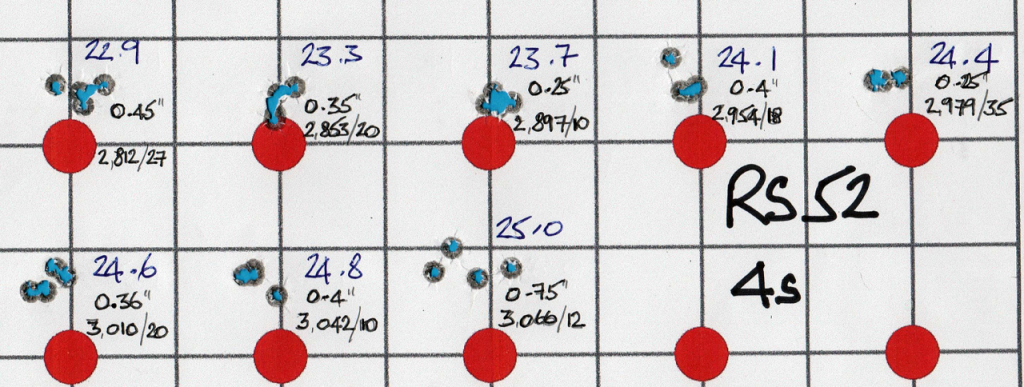

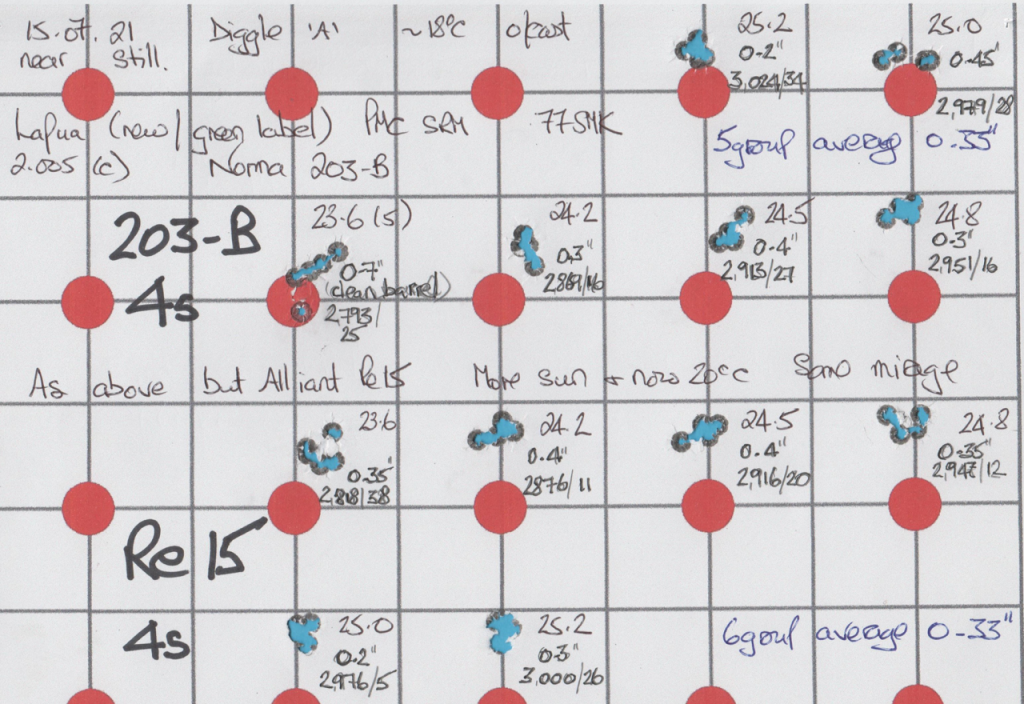

These tests and the reappearance of Norma powders in the UK, however temporary, gave me the chance to run a test within a test, that is to do a side-by-side comparison between Alliant Reloder 15 and Norma 203-B which I’ve long believed to be one and the same thing in different shape cans under different labels. Both are made by Eurenco Bofors at Karlskoga in Sweden; they have the same dimensions and look pretty well identical. (Note that while differences in these aspects can show two powders aren’t the same thing, same appearance / size on their own are unreliable guides to propellant identification and quite unusable in this role!) Published loads are very close and Norma’s unusual 308 Win pressures/MVs burning rate table gives them near identical results. Unfortunately, my results will be of little use here once remaining stocks of 203-B are sold, but handloaders elsewhere may find them useful.

25 rounds were loaded up for each, and as they remain part of the VGT alternatives series, all other components remain as for the other powders. A five-round starting load batch was followed by five 4-round batches with identical charge weight increments for the pair rising from 23.6 to 25.2gn. A single lot of new cases was used, the 50 rounds loaded in a single session, likewise tested sequentially during a single outing in excellent weather conditions. For background, I’ve long liked Re15 in 223, first with 80gn SMKs in a Wylde-chamber straight-pull AR, later with this Savage based rifle in its original F/TR guise shooting 90gn Berger VLDs at very impressive MVs from its then 31-inch barrel. It is however temperature-sensitive – the sole powder that has produced pressure issues for me in our relatively modest northern British top temperatures in the mid to high 20s C (low 80s F to those in North America). To be fair, that was in 90gn bullet 223, a combination that take no prisoners, and more to the point with a load that was pushing pressure boundaries in cool conditions.

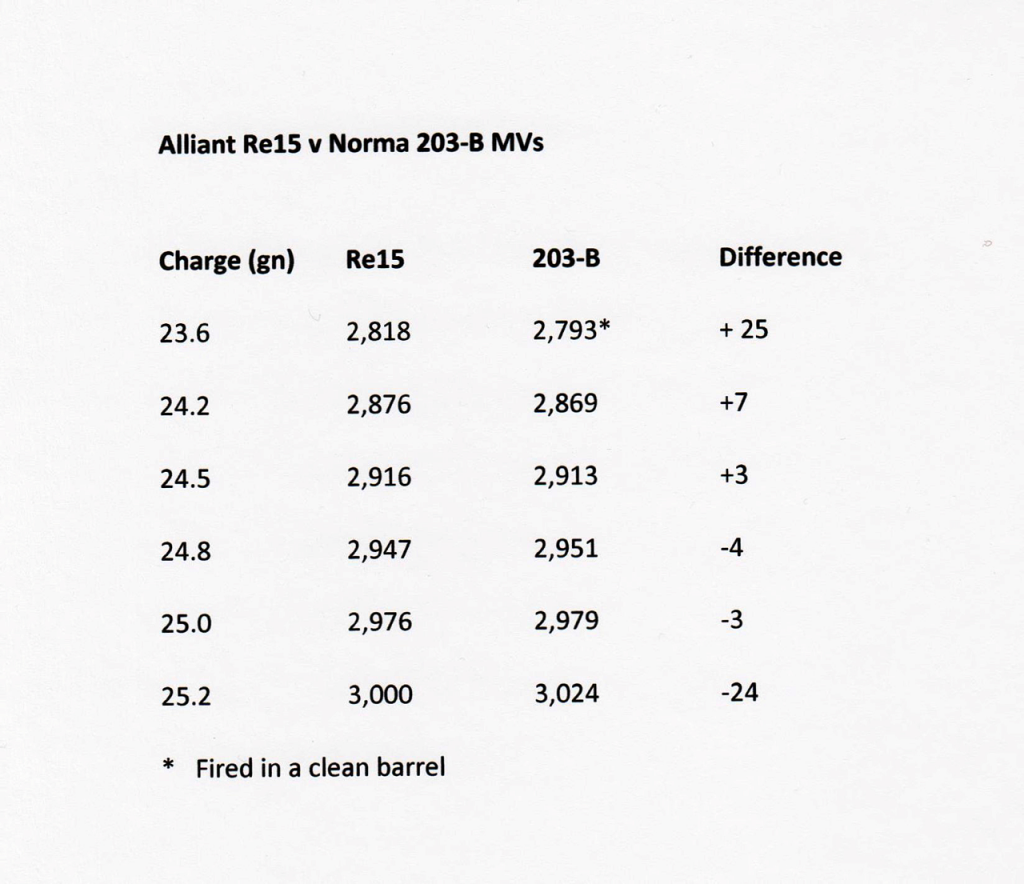

The target scan shows the results for the pair. (Note that 203-B in the top half has its two top loads situated above the others in the reverse of my usual practice, the scope’s elevation setting reduced too in order to keep shots on the paper). I was worried about comparing newly made 203-B against elderly Re15 (getting on for 10 years), but with one exception, MVs were remarkably close through the entire charge range. (See Fig 1). Oddly though, Re15 gave smaller across the board ES readings which I’m unable to account for. So far as groups went, both powders were good, each producing my iconic 0.2” example, and with 203-B’s starting load group excluded for being fired through a clean barrel, the pair gave an identical third-inch all-charge weights’ group average. With the pair maxing out at 0.4-inch across 11 four-shot groups, that’s remarkably consistent performance across a near 200 fps range. QL’s MV prediction for the 25.2gn top charge was close to the actual, so the pair should have been producing pressures right on the 55,000 psi mark in this long-throat chamber. (QL underestimated pressures for lower charge weights, the gap with actuals shrinking as charges rose. This is common as QL gives pretty well linear results according to charge weights whilst actual incremental MV/pressure changes often become larger as pressures rise, especially in the 223. In this case, MVs initially rose by around 12 fps per 0.1gn, increasing to 14 or 15 fps at 25gn charge levels).

As far as the Re15/203-B comparison goes, I’m now certain they are the same thing on the ‘duck test’. (If it looks like a duck, waddles like a duck, swims on ponds, and quacks …….. it probably is a duck). As Varget alternatives, they’re close to the Hodgdon grade, the MV discrepancy in Re15/203-B’s favour put down to its higher energy levels being a double-based powder. (Norma lists 203-B as having 7.5% nitro-glycerine content by weight). However, no matter how close VGT and Re15/203-B’s charges, performance and list of applications are, the Hodgdon powder retains its plus of greater temperature stability, a major factor for many competitors elsewhere that see far higher peak summer temperatures than we do, and/or greater changes. Hence of course, why Alliant now has the temperature-stable Re TS 15.5 grade in its listings which I look forward to trying when it eventually gets here.

‘Things’

Three things to finish this report off with – pressure signs, charge compression and, yet another powder availability update. I’ve mentioned primer condition a couple of times, but you might also remember that I’m usually very sceptical of the value of trying to ‘read pressures’ off this component. (Short of excess pressure symptoms such as primer leaks, major pocket expansion and suchlike). The combination of this Savage 12 PTA action, 223 Rem cartridge and the PMC SRM primer creates an exception to my rule. Having used this rifle with heavy, high-pressure, heavy-bullet loads over many thousands of rounds, I believe I have an idea what’s happening inside the case, primarily through the extent and nature of ‘cratering’ around the firing pin indentation. Savage actions rarely have really close firing pin to bolt clearances and this example is no exception. Cratering appears on the PMC SRM with loads / MVs that QL calculates as producing c. 53,000 psi and the condition becomes steadily more marked as charges and pressures rise further, in extreme cases resulting in primer ‘blanking’. There are other signs too, and all this occurs before pressures are such that the ‘circle of death’ (extrusion into the ejector button recess) appears on the case-head face. If I changed the primer model, I’d be back to square one, and I’ve several thousand shots’ worth of experience with the hard-cup PMC SRM in this rifle, so can calibrate this condition meaningfully. (Or, maybe I’m just fooling myself!).

On charge compression, many extruded powders produced this condition with their heaviest charges, so take its occurrence as read for top charges even with the 2.4” COAL. I’ll only remark on it should it become an ‘issue’. Powder availability? I’m told that Alliant Power-Pro Varmint has been ‘discontinued’ (I’m unsure whether that originates with Alliant, or more likely Edgar Bros ‘discontinuing’ imports) whilst its Power-Pro MR2000 stablemate is on order from the USA and we’ll have to see whether any comes or not in the next shipment from there. Winchester StaBALL is in stock at Edgar Bros. and by the time you read this, Simon Fox of Fox Firearms UK should have received a tin for me to try the powder in 7mm-08 as a supplement to the earlier H4350 replacement powders exercise.

So, that concludes the first of two reports on Varget alternatives. The next will be an all-Vihtavuori affair covering N140, 540, 150, and 550 grades.