Most shooters and handloaders know that the primer plays a vital role. For a start, should it fail, the firearm doesn’t work – period – with potentially disastrous consequences for some users and inconvenience for many.

As bad if not worse – as it’s a potentially very dangerous occurrence – is a partial or delayed operation, the ‘hangfire’. Hangfires most commonly occur in old cartridges, especially if they’ve been stored in poor conditions, hot and humid environments but can be caused by faulty, degraded, or badly seated primers. However, whilst a complete or partial misfire is obvious, inconsistent performance is more common and frequently hard to quantify, or even recognise.

Cartridges with primer ‘issues’ may well go ‘bang’ but could produce variable ballistics. Causes range from:

- Using mixed primer makes/types in an ammunition lot

- Deterioration through age or poor storage

- Incorrect choice

- Bodged seating in the case

- Manufacturing failings

The last named very rarely occurs, although an occasional ‘bad lot’ turns up. An interesting issue is that of matching primer-type and powder in extreme cold conditions, some combinations needing magnum types for 100% reliability and full pressures/velocities.

Even when the primer is superbly made and its specification well matched to the cartridge and propellant, it is only one part of the cartridge ignition system. The consistency and condition of the primer-pocket in the case-head, flash-hole and of course, mechanical aspects of the firearm (firing pin energy and protrusion) affect performance, sometimes severely.

Take that little hole that the primer’s eject passes through to get at the ignition charge, nominally 2mm (0.078”) diameter in most cartridges, 1.5mm (0.059”) in a few – the 220 Russian/PPCs, BR family, 6.5X47mm Lapua, and 308 Win Lapua ‘Palma’. If the diameter varies significantly within a batch of cases, so will the cartridges’ performance – this showing up in a large MV spread. Same thing if the flash-hole exit still has brass shards attached from when it was punched through the case-web during manufacture, or is left partially blocked by such brass debris.

Primer Seating Issues

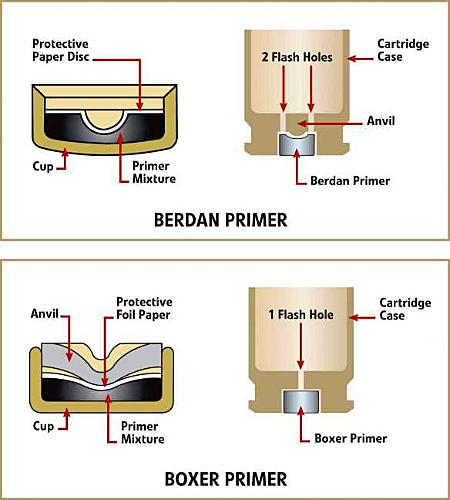

Returning to you and me, one of the easiest ways of producing inconsistent ammunition is to make a hash of seating the little beggar in its pocket. If you look at a sectioned drawing of the beast (fig. 1), you’ll see that Boxer-type primers consist of three, sometimes four components. The first is the brass cup, always brass despite there being ‘silver’ and ‘gold’ coloured examples out there, the former being lightly nickel plated. Large rifle primers all come with one brass thickness, a nominal 0.027” (unlike small rifle primers which vary from 0.020” to 0.025” depending on make/type).

Many shooters wrongly believe that BR or magnum models have thicker brass and are therefore ‘tougher’ than standard models, but whilst true for SR types, there are no such differences here. Undoubtedly though, there are hardness variations depending on the brass alloy mix, seeing some makes ‘harder’ or ‘softer’ than others and, there are likely lot-induced variations too. Any such differences shouldn’t be large enough to induce failure or ‘blanking’ with any reasonable pressure load but can and do make ‘reading fired primer condition’ potentially misleading.

Anyway, moving inwards from the closed end, we have an explosive pellet weighing around 1 grain that produces a high-velocity, high-energy stream of hot gas laced with tiny incandescent particles to get the cartridge’s main propellant charge burning and which also adds to its total energy content. (The priming charge’s energy is large enough to account for a significant percentage of the humble .22 Long Rifle’s total power.

The smallest rimfire cartridges such as ‘bulleted caps’ use primer energy alone in fact, as do modified centrefire revolver cases loaded with wax or nylon projectiles for indoor pistol shooting. There may then be a wafer-thin treated paper covering above the pellet to stop moisture ingress, optional as most manufacturers now use some sort of paint or lacquer sealant. Finally, a two or three-legged ‘anvil’ sits on top of everything at the ‘open end’. This is a small brass stamping like a shallow mini-tripod, its tip pointing backwards towards the priming pellet and its ‘feet’ facing the open end, therefore the bottom of the primer pocket in the case.

Ignition occurs when the firing-pin indents the cup, crushing the pellet against the anvil-tip. To work properly, the anvil’s ‘feet’ have to be anchored on the case pocket floor and its tip barely separated from the priming compound, or just nudging it. So, the primer should be seated to a snug fit within the pocket putting the anvil’s feet squarely on its floor and positioning the tip against the pellet.

This requires a seating tool with enough ‘operator feel’ to know when the primer has bottomed in the case-pocket and to then add a teensy-weensy amount of ‘crush’. If it’s not seated deeply enough, firing-pin energy is diverted to pushing the primer further into the pocket and may be reduced enough to degrade resulting primer detonation, or cause a misfire. Use too much force, and the cup is distorted or partially crushed, likewise its contents – if done hard enough, the explosive pellet can be damaged or broken leading to degraded performance, more likely a complete misfire.

Mixtures

I’ll look at primer-seating tools and primer-pocket/flash-hole uniforming in a future feature. Returning to our hot little component, what makes it go ‘bang!’, that is what do manufacturers put into their priming mixture recipes? Most rifle primers use lead styphnate as their primary ingredient. Fuel/oxidiser compounds are added to increase the eject gas temperature and volume for rapid and complete main-charge ignition. (Potassium chlorate, the source of the problem in ‘corrosive’ primers performed this role for decades).

Metallic compounds, finely granulated metal, powdered glass are optional additions should one wish to produce incandescent particles that penetrate deep into the powder column. The amount of lead styphnate determines a primer’s ‘brisance’ (literally, its ability to break things), ‘hot’ examples heavily loaded, but the overall ingredient mix is varied to suit the primer’s purpose.

An important thing to remember about lead styphnate is that it’s a ‘primary explosive’, that is detonation (not combustion) occurs as a result of the application of physical shock, heat, or electrical charge and as a result it is very sensitive … dangerous in other words. Primary explosives are never used in main charges, rather in detonators or fuses whose operation produces enough heat and shock to cause a chain-reaction detonation in otherwise stable explosive compounds ranging from the terrorist’s homemade filling for an IED through to every form of explosives used in commercial or military applications.

Whilst most shooters correctly believe that the greatest risk in handloading is a ‘wrong-side’ mistake in powder choice or charge-weight, priming presents a serious primary risk. That single grain weight of explosive mixture will shatter the brass cup and anvil ejecting fragments out several feet with more than enough force to cause penetrating injuries, especially to the eyes – wear eye protection while priming cases! Don’t think you’re safe if an unplanned detonation occurs during primer seating either – even when it has been pressed home fully in the case. Without the rifle bolt sitting against the case-head, the primer will be blasted straight back out at a frightening velocity.

Note too that the primary ingredient is a lead-based compound. Isn’t lead a toxic heavy metal that has become an international public enemy and been regulated out of lots of products such as fuel additives? You bet! When you fire your smokepole, you do create a tiny amount of lead pollution. This isn’t a problem for the outdoor shooter, but can be for short-distance indoor ranges that see large ammunition expenditures, so commercial pistol and rimfire cartridges now use lead-free priming compounds. The reason that it survives in most rifle models is that nobody has yet come up with anything that works as consistently and well as lead styphnate, nor keeps as well in storage.

Military requirements determine primer specifications and NATO has consistently rejected lead-free types after exhaustive testing. In fact, the primers that you buy in gunshops are variants on a model developed in the early 1950s for the US Army for the then new 7.62mm NATO cartridge. Tiny though the amounts of lead dust are, it’s another good argument for keeping your loading press and bench clean and washing your hands after handling fired cases and spent primers.

Choices, Choices

As this feature is about primer performance, let’s get onto the testing and its methodology. Simply getting supplies of any model recently, not to mention stiff price increases, have been the big issue for most handloaders and shooting forum topics about substitutions are common – standard and sensible advice being to drop the charge weight by a grain and finesse the load back up. Perversely, I’ve never had so many different types, albeit most in penny packet numbers and/or from old lots – a grand total of 16 models – although I subsequently learned that two are probably from the same source in different packaging.

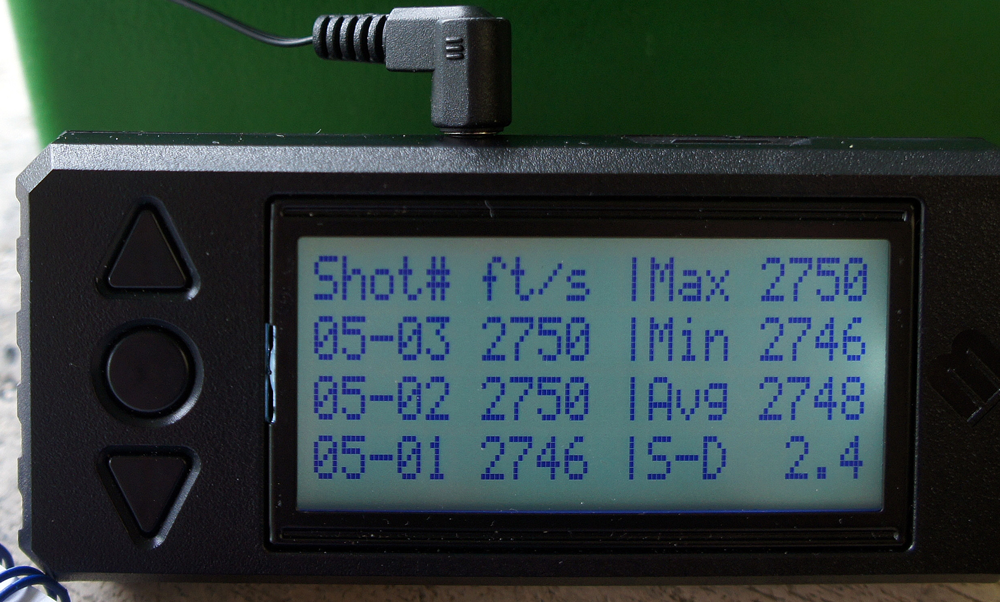

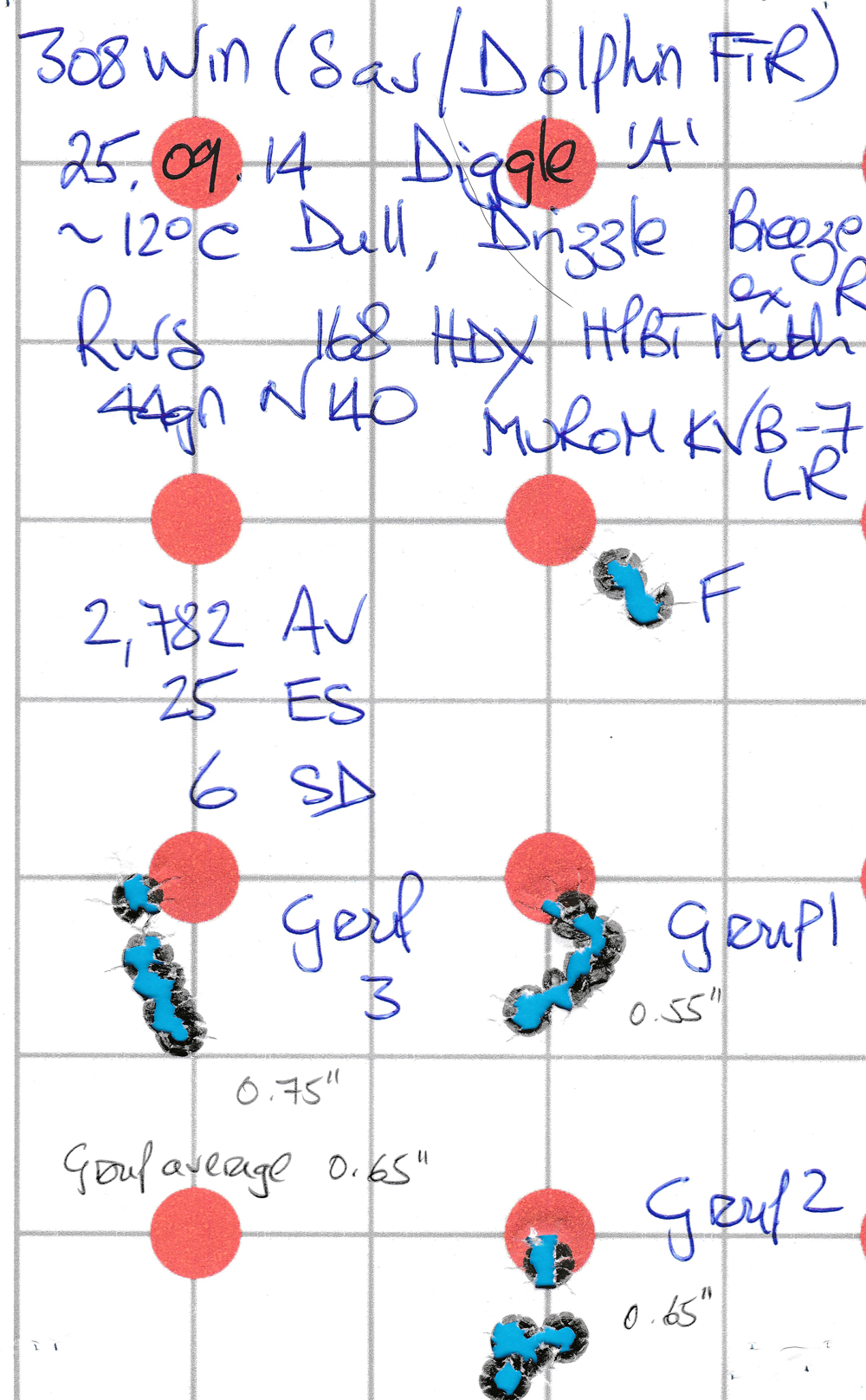

So, I thought I’d carry out a long planned project of running side by side tests. This was aided by having a 308 Win FTR rifle with some spare barrel-life before a planned replacement, other suitable components and crucially, a MagnetoSpeed V3 barrel mounted chronograph. As the tests would have to be conducted over the course of several sessions, I couldn’t have relied upon an optically based chronograph as experience had shown that ambient light level changes affect readings. As any primer-induced variations should be relatively small, chronograph consistency is essential.

Objectives and Tools

The rationale for doing side-by-side tests is to see what effect primer choice has on ballistics, that is average velocities and MV consistency. There are a great many views on the subject, a few based on tests including primer flame photography but most apparently hearsay. For instance, I’ve read that the Remington 9½ standard type is ‘hot’, but also seen the opposite. Magnum versions are ‘hot’ and best avoided for small to mid size cartridges like 308 Win, 30-06 and 270 Win. Russian primers (originally branded ‘PMC’ here, now occasionally available as ‘Murom’) are ‘mild’. Many opine that ‘match’ versions are a waste of money as they are just specially inspected lots of their standard brethren in different packaging. Why does ‘hot’ or ‘mild’ matter as long as each model behaves consistently? Many cartridges including the 308 with its 42-50gn loads of easily ignited propellants give smaller velocity extreme spreads (ES) with a mild number. This may or may not produce smaller groups in itself but, it undoubtedly reduces velocity-inspired vertical dispersion on targets at longer ranges.

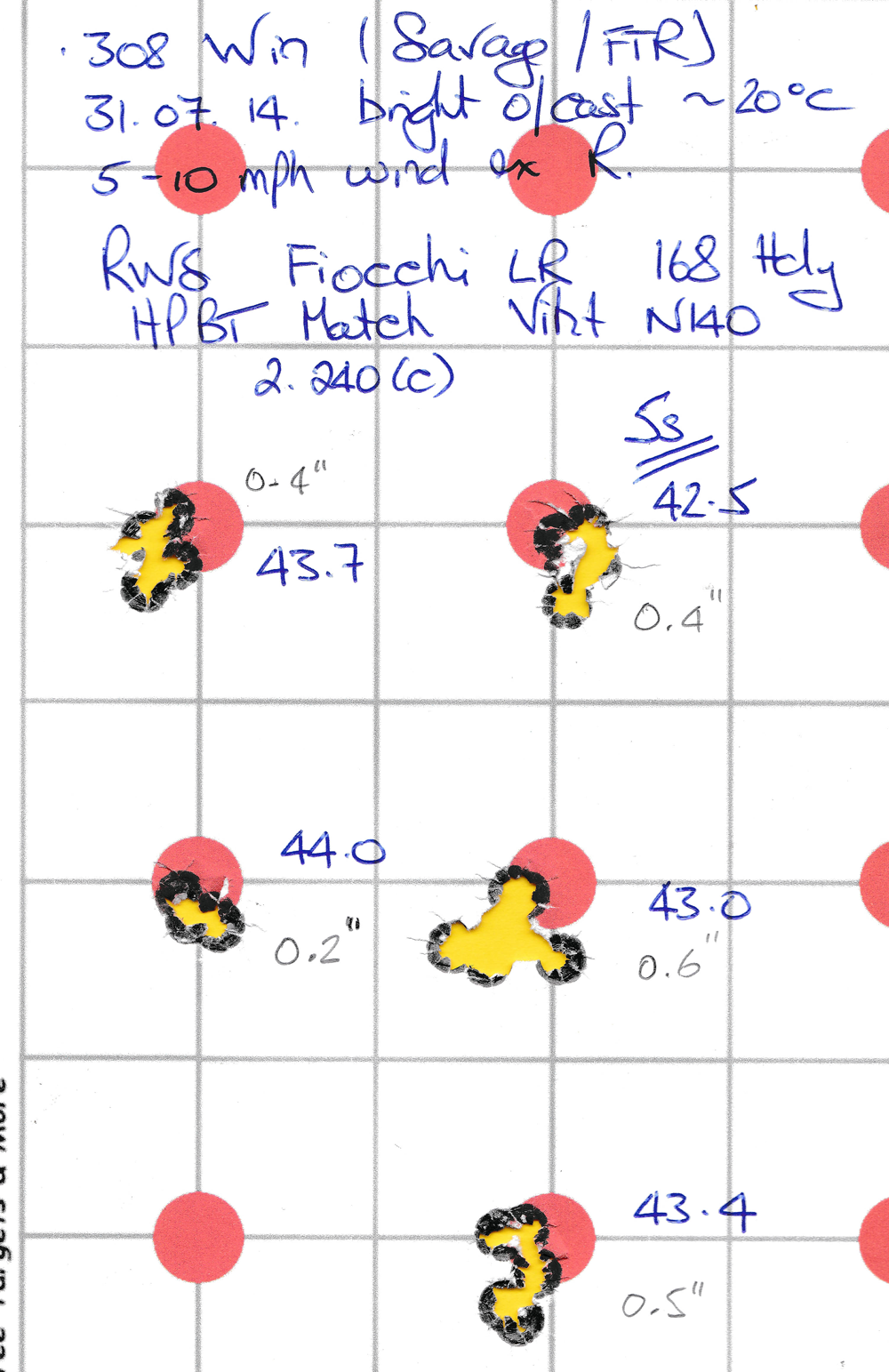

The other components used were: Hornady 168gn HPBT Match bullets, a longstanding successful if short-range model; Viht N140 from a single 2012 dated lot; 100 RWS cases with one previous firing. COAL was 2.860 inches which put the bullet some 20 thou’ off the rifling in the rifle’s match chamber. Cases were trimmed, full-length sized in a Redding ‘Type S’ bushing die first time round, on subsequent reloadings neck-sized/shoulder-bumped in a Forster Bushing-Bump type with minimum neck-working before expanding with a Sinclair E30 mandrel to provide light neck-tension. Primers were seated using a hand tool, either a Lee Auto-Prime XR or recently introduced Lyman E-ZEE model.

The rifle was an Osprey Rifles built FTR example using a Savage PTA single-shot action, 32-inch Bartlein 1-12 twist ‘Heavy Palma’ profile match barrel, these mounted in a Dolphin Gun Company modular stock with an F-Open/Benchrest forend fitted here to run on a front-rest. Test batches consisted of 16 or 17 rounds for each primer, charges thrown by an RCBS ChargeMaster and checked on lab quality electronic scales, adjusted if necessary to within ± 0.04gn, so any charge weight variation would be under 0.1gn which equates here to 5 fps.

Test procedure

Each test started with a clean, cold barrel with one/two fouling shots, then 15 fired for record with a pause after 10 rounds to let the barrel cool. Individual MVs were noted alongside the string average, ES and standard deviation (SD). Shots were taken carefully in three 5-round groups, these measured and averaged – although group size is less important than ballistics in this exercise and the MagnetoSpeed hanging on the muzzle affects barrel harmonics.

Initial load development had been carried out beforehand without the MagnetoSpeed. Five, 5-round batches, working charges up from 42.0 to 44.0gn N140, the latter providing best precision with a 0.2-inch (100 yard) group. The 44gn charge exceeds Vihtavuori’s cautious maximum but other manuals’ loads data see maxima of up to 44.5gn and QuickLOAD predicted 55,077 psi PMax for 2,797 fps MV, The latter spot-on as it turned out and still provided a safety margin should other primers produce significantly higher values. (Bear in mind my rifle’s long-throated chamber, which reduces pressures!). This lot used Italian Fiocchi primers, which have replaced CCI-200s as my general-purpose caps and given me excellent results in several cartridges.

Velocities

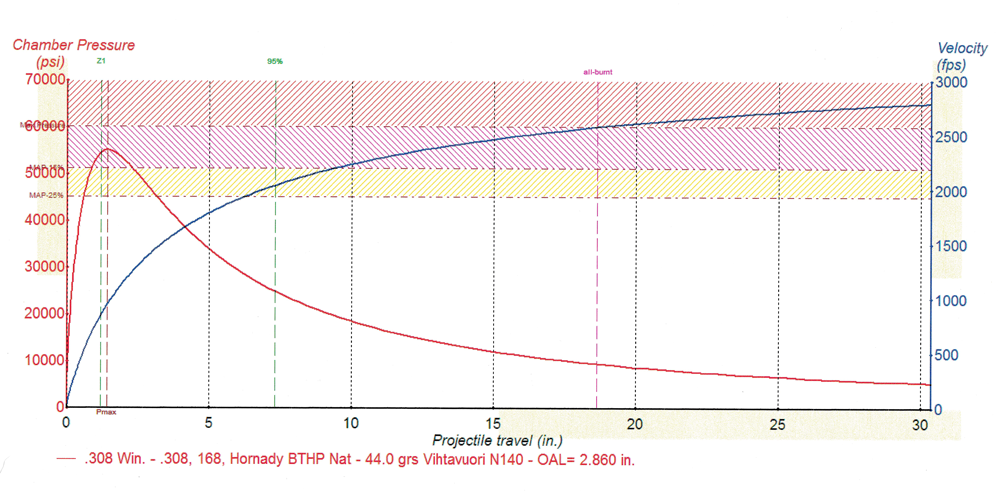

Primer choice affects MV, it’s as plain as that. The MVs recorded (Table 1) saw average values cover a 35 fps range, equivalent to a 0.7gn N140 charge variance. However, it’s not that straightforward. MV is a function of the total amount of pressure provided by the primer and propellant, the size of ‘the area under the graph’ (Fig. 2). Whilst the powder-burn accelerates the bullet throughout the barrel, albeit with reducing pressure after the first fraction of a millisecond of burn, pressure spikes very shortly after ignition and that’s what determines the maximum safe load. With the primer compound detonating, not burning like the main charge, it produces a ‘pressure-rush’ which enhances that initial peak, so the ‘oomph’ which produces an extra 35 fps at the muzzle will likely affect PMax disproportionately – the ‘wrong sort’ of pressure! I’ve graded results as ‘mild’ (2,780-90 fps); ‘warm’ (2,791-2,800 fps); ‘hot’ (>2,800 fps).

Images

Table 1 – Average MVs in ascending order

| Mild | Warm | Hot | |||

| Remington 9½M* | 2,780 | CCI-200 | 2,795 | CBC Magtech 9½ LR | 2,801 |

| Norma Superflash (1980s) | 2,781 | PMC LRM (Murom KVB-7M)* | 2,795 | Federal 215M*† | 2,803 |

| CCI-250* | 2,782 | Winchester WLR | 2,807 | ||

| Murom KVB-7 | 2,782 | Remington 9½ LR | 2,815 | ||

| Kynoch (1970/80s vintage) | 2,783 | ||||

| Sellier & Bellot LR | 2,787 | ||||

| CCI-BR2† | 2,787 | ||||

| Federal 210 | 2,788 | ||||

| Fiocchi LR | 2,788 | ||||

| Federal 210M† | 2,790 | ||||

Notes: * = ‘magnum’ primer model. † = ‘match’ primer. The Kynoch primers were probably made by Norma, so are the same product under two names.

So what does this tell us? Some of the average MVs for the 15-round strings fulfilled expectations, others quite the opposite. High velocities (hence increased pressures) were generated by the notoriously ‘hot’ Winchester WLR and Remington 9½, so came as no great surprise, likewise the Federal 215M magnum/match. The PMC/Murom KVB-7 and CCI-BR2 were as predicted ‘mild’. Low MVs from two other ‘magnums’, Remington’s 9½M and CCI’s #250, were however quite unexpected, both at the ‘mildest’ end of the spectrum.

ES and SD

However, velocities don’t tell the full story – consistency matters more to seekers of precision and we measure that through the extreme spread (ES) of velocities recorded (highest MV minus lowest), and the standard deviation (SD) around the arithmetic mean value. Actually a 15-shot sample size is barely adequate to produce a meaningful SD as it only takes one shot out of the pattern to seriously increase its size. Nevertheless, a low SD indicates most shots fell close to the average, whilst a high one shows a wide scatter. Table 2 shows results for both values ranking them by SD.

Table 2 – Extreme Spreads and Standard Deviations (ranked by SD in ascending order)

| Primer | ES/SD (fps) | Primer | ES/SD (fps) | ||

| 1 | Sellier & Bellot LR | 12 / 3.1 | 9 | Norma Superflash | 35 / 8.4 |

| 2 | Federal 210 M (match) | 23 / 6.0 | 10 | Kynoch LR | 31 / 8.9 |

| 3 | Murom KVB-7 (PMC LR) | 25 / 6.0 | 11 | Winchester WLR | 35 / 9.1 |

| 4 | CCI-BR2 Match | 20 / 6.6 | 12 | Fiocchi LR | 36 / 9.3 |

| 5 | Federal 215M (magnum / match) | 20 / 6.7 | 13 | CCI-200 | 28 / 9.5 |

| 6 | PMC LR Magnum (Murom KVB-7M) | 25 / 6.7 | 14 | Federal 210 | 38 / 10.8 |

| 7 | CCI-250 Magnum | 26 / 6.8 | 15 | Remington 9½ LR | 39 / 11.8 |

| 8 | CBC Magtech 9½ | 31 / 8.1 | 16 | Remington 9½M (magnum) | 47 / 14.0 |

Again, some expectations were fulfilled and others confounded. Received wisdom says ‘mild’ numbers are more likely to produce consistency; ‘hot’ caps induce larger spreads and higher SDs. Confirming the former, first to fourth places did indeed go to ‘mild’ examples and the ‘hot’ Remington 9½ is at the back of the field in 15th place. However, its apparently ‘mild’ (based on velocity) 9½M Magnum stablemate produced the largest ES and SD values of the bunch to see it last in this particular contest. Conversely, the other ‘magnums’ from Federal (215M), PMC (Murom KVB-7M), and CCI (#250) performed very creditably in 5th to 7th places. To my great pleasure (always nice to have one’s purchase decisions validated) Federal’s 210M, CCI’s BR2, and the much praised Russian Murom KVB-7 ranked highly, the Fed and CCI doing much better than their cheaper ‘cooking’ F210 and CCI-200 versions. In fact, the Federal 210’s poor showing was my greatest disappointment in these tests. Interestingly, some national level F-Class and FTR shooters confirmed this in their subjective impressions of the current lot of this model – much poorer than that of previous lots.

The Fiocchis’ performance surprised me too as they’ve performed superbly for me. I do have a hypothesis to explain this. This make proved to be a very tight fit in the once-fired RWS case pockets, so much so that considerable pressure was needed to seat some. I believe that this saw larger than desirable variations in the primers’ seated positions and tensioning of their anvils. Moving on, the outstanding performance – and biggest surprise to me at any rate – came from an elderly (at least 10 years) lot of Czech Sellier & Bellot standard caps with an ES of 12 and SD of 3.1 fps, way below those of the nearest competitor. By contrast to the Fiocchis, they were an almost slack fit in the cases and this may have contributed to their consistent performance. (The downside is that they’d soon be too slack as case-heads/pockets expand over subsequent firings).

Norms

Whilst that 12 fps ES is obviously good, what should we expect? The 308Win. is an efficient, well behaved design and I’d expect values in the 20s to mid 30s with high single-figure SDs from any reasonably happy load combination using quality components in a good rifle but without any special treatment, preparation, batching and suchlike given to the brass. The RWS cases were full-length sized initially, trimmed and chamfered. Subsequent loadings saw them run through a Forster Bushing-Bump neck-sizer with shoulder positions regulated but there was no neck turning, flash-hole reaming, primer-pocket uniforming or other ‘tricks’ applied. The reason for shoulder ‘bumping’ is that there is a lot of evidence that neck-sized only brass which sees a range of shoulder positions some resulting in a slight crush fit in the chamber exhibit a wider range of pressure and velocity variations than those with an optimal 0.001-0.002” shoulder clearance.

Anyway, the occasional round needed more or less pressure on the press handle than the norm during bullet seating indicating neck-tension variations. Likewise, bullets were used straight out of the box without any base to ogive length checks and both sets of variations are likely to affect pressures and MVs adding random effects to those induced by the primers.

With my fully ‘prepped’ and batched Lapua or Norma standard LR case 308 match ammunition, I expect ES values in the teens, at the very worst just breaking 20 fps, over 10-shot strings. Similarly cosseted Lapua ‘Palma’ case rounds and their Small Rifle primers reduce that to high single/barely double figure levels. MV consistency does not guarantee small groups but it’s a necessary adjunct to such precision at long ranges to help obtain consistent ‘elevations’ on the target.

So, given the lack of effort put into the brass and the resulting likelihood of occasional rogue results, a third set of values was calculated which omitted the two extreme values of the 15 velocity readings, ES and SD recalculated on the remainder as shown in Table 3.

Table 3 – ‘Best 13’ Extreme Spreads and Standard Deviations (ranked by SD in ascending order)

| Primer | ES/SD (fps) | Primer | ES/SD (fps) | ||

| 1 | Sellier & Bellot LR | 7 / 2.6 | 9 | CCI-BR2 Match | 17 / 5.4 |

| 2 | Federal 215M (magnum / match) | 13 / 4.0 | 10 | Winchester WLR | 19 / 6.1 |

| 3 | Murom KVB-7 (PMC LR) | 11 / 4.6 | 11 | Fiocchi LR | 16 / 6.8 |

| 4 | Norma Superflash | 15 / 4.6 | 12 | Kynoch LR | 20 / 7.1 |

| 5 | CCI-250 Magnum | 16 / 4.9 | 13 | CCI-200 | 23 / 8.3 |

| 6 | PMC LR Magnum (Murom KVB-7M) | 15 / 5.0 | 14 | Federal 210 | 29 / 8.3 |

| 7 | CBC Magtech 9½ | 17 / 5.0 | 15 | Remington 9½ LR | 30 / 8.3 |

| 8 | Federal 210 M (match) | 15 / 5.1 | 16 | Remington 9½M (magnum) | 42 / 10.1 |

Unsurprisingly given its initial position, the Czech S&B stayed in the lead with the 13 MVs now in a single figure spread. The tail end Charlies in 13th to 16th places also remained unchanged obtaining little benefit from the revision. Of those in between, many saw large ES reductions, Fiocchi dropping from 36 to 16 fps for example and 11 of the 16 primer models were now inside 11-20 fps ES. Whilst the Remington 9½M hardly improved to retain its lowly 16th and last slot, the other ‘magnums’ now took three of the top six places. This flies in the face of received wisdom! Finally, table 4 lists average group size bringing these lies, damned lies, and statistics to a close.

Table 4 – Average of three 100 yard 5-round groups

| Primer | Group Av | Primer | Group Av | ||

| 1 | Remington 9½ LR | 0.43” | 8= | Sellier & Bellot LR | 0.57” |

| 2 | Fiocchi LR | 0.48” | 8= | Remington 9½M (magnum) | 0.57” |

| 3= | Federal 210 M (match) | 0.5” | 11 | CCI-BR2 Match | 0.58” |

| 3= | Norma Superflash | 0.5” | 12= | CCI-250 Magnum | 0.6” |

| 3= | Winchester WLR | 0.5” | 12= | CCI-200 | 0.6” |

| 6 | Federal 215M (magnum / match) | 0.53” | 14 | PMC LR Magnum (Murom KVB-7M) | 0.63” |

| 7 | Federal 210 | 0.55” | 15 | Murom KVB-7 (PMC LR) | 0.65” |

| 8= | Kynoch LR | 0.57” | 16 | CBC Magtech 9½ | 0.7” |

‘Palma’

I’ll run another series of primer tests over the summer of 2015, again using the 308 Winchester but now with Lapua ‘Palma’ small primer brass. If I can get hold of samples of a few types I don’t currently hold, this will encompass 14 models from 10 manufacturers including one most people have never heard of, Vihtavuori. Yes, the Finnish powder manufacturer had primers in its products range some 30 years ago, although as with the Kynoch LR model, they were probably made by somebody else, most likely Norma or Murom.