Do you tumble your brass? No, neither do I. But, I do have a tumbler – a legacy from the pistol days when brass tumbling was an essential part of the reloading process. Pistol cases landed on the range floor or, when shooting outdoors, they were often trodden into the mud. As soon as you got home the cases went into the tumbler.

My tumbler is – I won’t mention the name – a green vibrating one, purchased in 1984. When the motor packed in after more than a decade of continuous use, it was replaced free of charge. I’ve no complaints regarding my existing tumbler but it doesn’t work too well on rifle brass so I don’t bother with it.

The only parts of a case that I need to be clean are the neck (inside and out) and the primer pocket. My green machine doesn’t do a particularly good job in these two critical places so I don’t bother and do it by hand. In the pistol days, I would be dumping hundreds of mainly 45ACP cases into the tumbler but, rifle shooters are a bit more precious with their brass – I normally load no more than 25 or 30 for a comp. so it’s hardly worth using a tumbler anyway.

On a recent visit to Hannam’s Reloading, Pat was keen to show me the latest Lyman case tumbler. The Lyman Cyclone consists of a rotating drum rather than the vibrating type. I’d seen the Lyman previously at gun shows and it did seem to do the job – mainly because of the stainless-steel ‘media’ used – as opposed to ground up walnut shells or what have you. The tiny steel pins are 7.5mm in length and one millimeter in diameter. A 5lb pack comes with the machine and they can be re-used indefinitely.

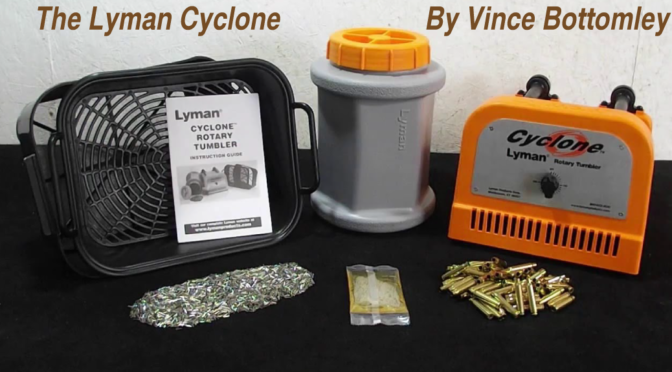

OK, let’s open the box and see what we have inside:

A motor-driven platform with timer

A drum

The stainless pins

A small sachet of detergent

Two strainer trays – one to catch the brass and another with a very fine mesh to catch the pins

Electrical plug lead

Instruction booklet

The instruction book is reassuringly thin – I hate reading instructions! But I did and it only took about a minute.

In my reloading room, I have a couple of large plastic tubs of used brass. Since I weighed in all my pistol cases at the hand-in in 1997 and got handsomely paid, I’ve never thrown a case away since. I must have easily 5000 – covering everything from 223 up to 45-90. At random, I grabbed a few handfuls and counted out 200 for the Lyman and 100 for the green ‘un. Honestly, some are really horrible – in fact most are – well used, with verdigris as well as burnt on powder and general crud!

I de-primed 300 cases – most are 308 but there’s a bit of everything. I dumped 100 in the green tumbler and the remaining 200 in the Lyman drum. The Lyman instructions say to add the 5lb of steel pins and cover the lot with water. Then add 1 fluid ounce of the cleaning solution (supplied) which looks like a thin washing-up liquid. Put the two-part lid on the drum and switch on both machines. It’s 5.00pm – after two hours we’ll compare the results from both.

One nice thing about the Lyman, you set the time and then it switches itself off. OK, you could easily rig up a timer on the green ‘un but I’ve never bothered. One thing in favour of the green one – it’s relatively quiet if you’re using it indoors – just a gentle hum. The Lyman is noisy – you’d definitely want it out of earshot – a sort of threshing sound!

When I opened the Lyman drum two hours later – and it hadn’t leaked a drop – I was greeted with lots of foam, wet cases and pins. With the media tumbler, it’s just a matter of fishing out the cases one by one, chucking them in a colander and giving them a shake to get rid of the media. Of course, you still need to inspect every case as many will have a crumb of media stuck in the flash-hole.

If the odd grain of media stays inside the case I doubt it would have a detrimental effect to shot-placement or barrel. Removing the stainless steel pins is another matter – I wouldn’t like to fire one up the barrel!

Here’s how we remove the pins. Put the two supplied trays together with the fine mesh tray on the bottom. Put the whole lot in the kitchen sink and tip the contents of the drum into the top tray – foam, water, pins and cases. Now, fill the sink with clean water so that the whole lot is completely submerged. Then, pick out the cases one by one, with the base uppermost so that the water and any pins fall back into the tray. When I carefully inspected the cases, I didn’t find a single pin inside.

When all the cases are on your draining-board – preferably on some tissue – you can lift out the two trays. All the pins will be in the bottom tray. Leave them in there until you next use the tumbler or, if you prefer tip ‘em back into the drum. It doesn’t matter if they stay wet, they won’t rust. Because I was taking the tumbler back to Hannam’s, I just left the pins to drain and dry naturally and, by the next day, they were.

You can also leave the cases to dry naturally but, if you’re in a hurry, you could put them in the oven on a baking tray for a few minutes.

OK, so that’s the process but is it worth it? Well, you can see from the pics – after just two hours, the Lyman cases are literally like new – the tumbler has done a super job.

Two hours in media wasn’t really long enough for the green machine – they could have done with another hour or two. Unfortunately, the primer pockets didn’t look much different to when they went in whereas the Lyman had done a great job on the pockets – see pics. The Lyman also cleaned the inside of the case-necks whereas the other machine left them dirty. Both machines cleaned the outside of the cases to an acceptable level but the Lyman left them bright and shiny.

The Lyman is certainly a great tumbler and, if you shoot a lot of rounds and clean your brass regularly, you need to have a look at this product. Personally, I’m going to stick to what I do – clean the primer-pocket with a carbide hand-tool, clean the outside of the neck with Duraglit wadding and the inside neck with an old bronze bore brush in an electric drill but, if you shoot and reload hundreds of rounds at a time and you like your brass spotless, the Lyman is definitely worth a punt.

I took my cleaned brass back to Hannam’s and hopefully, if you stop by you can see for yourself how effective the Lyman tumbler is. The retail cost of the Lyman tumbler is £220. Contact Hannam’s Reloading at sales@hannamsreloading.com or website www.hannamsreloading.com

Check out the Lyman website at www.lymanproducts.com or even You Tube – there are a couple of reviews on the Cyclone.