Tangential Topics: Compressed Charges

DISCLAIMER The load data contained in this article is intended for use with specific components and were safe in the author’s rifles. Other manufacturers’ components and other firearms may not produce equivalent pressure or velocities. Therefore it is recommended, as always, that the reader consults the appropriate reloading data supplied by each powder and bullet manufacturer and does not exceed their recommended loads.

When writing handloading features, things come up that merit a closer look but would involve chasing off after tangents if done at the time. One such was compressed charges (aka ‘compressed loads’) in my recent report on slow burning Vihtavuori N500 series powders in the 260 Remington.

Some shooters, especially those who air their opinions loudly on Internet forums, become upset at the mere mention of the C-word. “Compressed loads are DANGEROUS! Everybody knows that!” they thunder. In this case at least, ‘everybody’ doesn’t, certainly not the bullet, powder and ammunition company people who test loads in pressure barrels. Nevertheless, there is an intuitive basis to such views. It seems very wrong to force the bullet down into the powder column – worse, to feel kernels crunching under the descending bullet base.

What are the facts as opposed to opinions/intuition? Over 40 years of handloading, I must have read many tens if not hundreds of thousands of words on the activity from multiple sources and cannot recall serious concerns over compressed loads, albeit with a few exceptions referring to specific circumstances. You’re more likely to find warnings on the disadvantages, sometimes dangers, of excessively low fill-ratios.

I perversely retain great affection for and trust in those quaint old fashioned things called books, written by experts and that includes print handloading manuals. So, what do today’s manuals say?

Sierra (edition VI Reloading Manual) doesn’t address the topic directly in its reloading processes or safe reloading practices sections but, it comes up in its list of frequent questions received by the Sierra support team:

“In my 270 Winchester, your top load for a 130gn bullet and H4831 powder fills the case. If I’m compressing the powder slightly when I seat the bullet, can this load be safe?”

Answer: “There are a number of extremely slow-burning powders that will create this same situation. In the case of these bulky powders, frequently pressure is not the limiting factor in developing a load; case capacity is. ……….. In these situations, the compression is completely normal and not a cause for concern.”

Hodgdon says on the notes to its online Reloading Centre data:

“Hodgdon notes in its reloading data if the subject charge is a compressed load. A full case, or lightly compressed charge is an ideal condition for creating loads with the most uniform velocities and pressures, and oftentimes, producing top accuracy.”

Nosler’s technical notes attached to loads tables for the many cartridges that have compressed loads listed in its new 9th edition manual state:

“In certain cases, load densities will exceed 100%. This is what is called a ‘compressed load’ and is no cause for concern. All powder charges have air space around and between the granules, which can be compressed to a certain extent when the bullet is seated.”

……… and for those who’re still worried, from its online blog FAQs:

“Why are there compressed loads (more than 100% load density) listed in your Reloading Manual?

All compressed loads in any of Nosler’s published data are safe to shoot and are under SAAMI maximum recommended pressure. When seating the bullet on a compressed load, you will most likely hear/feel the crunching of powder granules – this is normal. As long as you are following Nosler’s load data requirements, compressed loads are safe to shoot. Like all Nosler load data, compressed loads are a well-balanced combination of powder burn rate, cartridge case capacity and safe pressures deemed by SAAMI.”

Lyman gives the topic more attention with a full page, photograph and illustrations in its 50th edition Reloading Manual. It’s also more cautious. After the usual descriptions/causes of the phenomenon, then a technique to recognise ‘excessive compression’, it concludes with a highlighted Caution:

“Excessive powder compression can lead to potential problems with proper propellant ignition. Sometimes this can cause dangerous conditions. Never use excessively compressed powder charges.”

We’ll return to identifying problem issues with excessively compressed loads, but the widespread use of non-numeric qualifiers such as ‘mild’, ‘heavy’, or ‘excessive’ is of little help to many handloaders, especially tyros, hence people tend to either accept the condition in whatever form it takes or seek to avoid it like the plague.

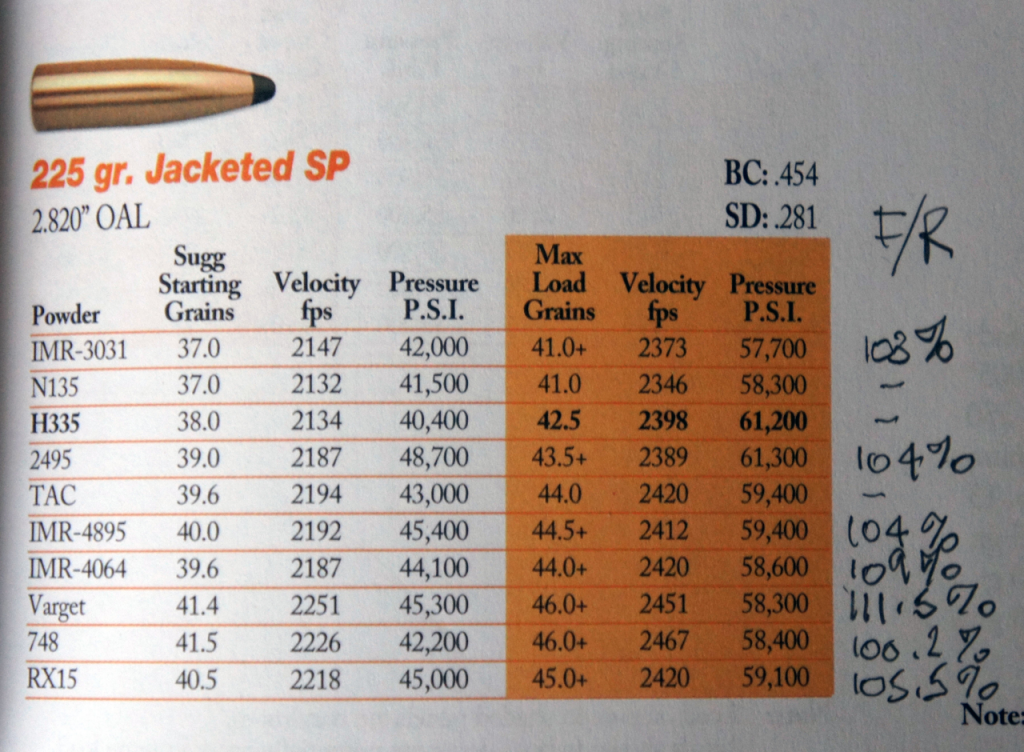

Lyman marks compressed loads in its manual with the + character after the charge weight but gives no indication as to the degree. Let’s look at its loads for the 338 Federal loaded with the 225gn Nosler Partition flat-base SP to 2.820-inches COAL. Seven out of ten maximum charges display the indicator. Running them through QuickLOAD, their calculated fill-ratios range from barely compressed, (Winchester 748 at 100.2%), to the 46.0gn maximum for Hodgdon VarGet at 111.5%.

100% fill-ratio is the space below the bullet fully occupied by powder as poured; anything higher represents a compressed charge. If 46gn VarGet generates 111.5% fill-ratio, the uncompressed charge weight is 41.25gn. So, imagine a case-load of powder that reaches the bullet base, then another 4.7gn poured in before bullet seating and squashing it down. This in a 308 Win size case! Hmmm, that seems a lot, so Lyman’s definition of ‘excessive’ has to be pretty extreme! Most of Lyman’s marked loads for this and other cartridges are for lower values, under 108%.

Not all manuals or online data-sets provide compressed load indicators and, of those which do, some seem to only show severe examples. I think this omission is a negative aspect of Sierra’s otherwise excellent new edition VI manual. The user trying an unfamiliar powder may unexpectedly discover powder reaching or extending well up the case-neck only on examining charged case fill-levels in the loading block during the final pre bullet seating safety check. Many inexperienced handloaders will take fright and discard excellent combinations, even pour out carefully weighed charges and restart using lighter and potentially inferior charge weights believing they’ve done something wrong.

Sierra gives data for 15 propellants under its 225gn Pro-Hunter flat-base in the 338 Federal (2.800” COAL).Two aren’t in my version of QuickLOAD, but running the other baker’s dozen, eight (all extruded) are compressed, mostly lightly which I define as fill-ratios below 105%. Only max charges of Accurate-2495, IMR-4064, N140, and Hodgdon VarGet produce ‘moderate’ levels ranging from 106 to 110%.

Factors

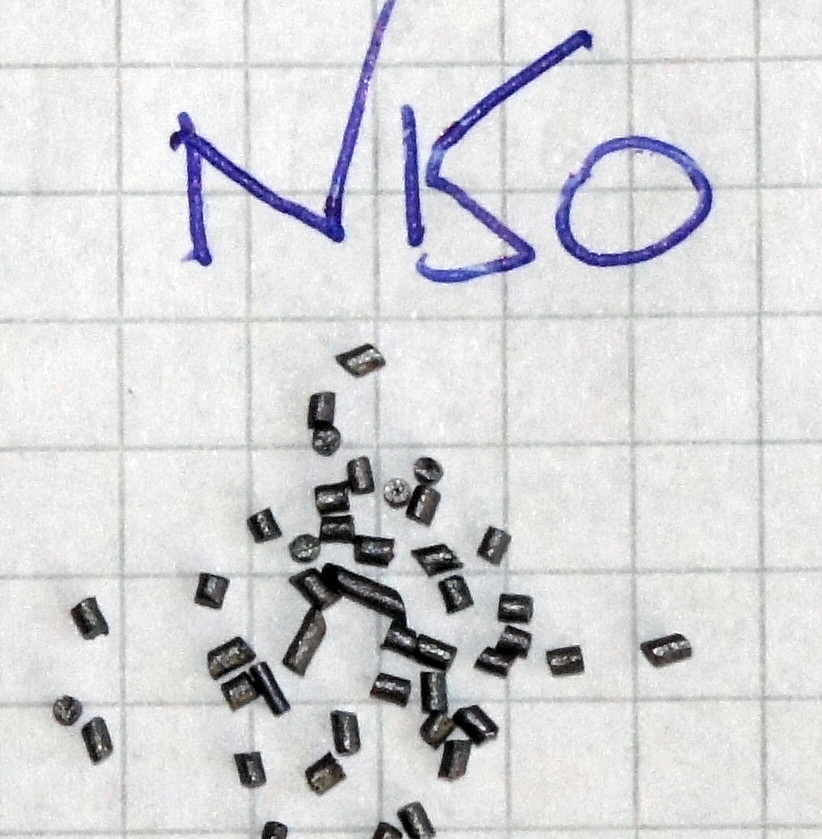

What determines or influences fill-ratios? First and obviously, choice and charge-weight of the powder grade. How much room a given charge-weight takes up depends on its bulk density. Canister powders vary from around 850 grams weight/litre volume to the high 900s g/ltr. Reasonably short-cut extruded rifle powders such as Viht N140 are just over 900 g/ltr, while the densest ball grades nudge 1,000. So, whilst N140 might be moderately compressed, the same weight of Hodgdon CFE-223 might just fill the space under the bullet.

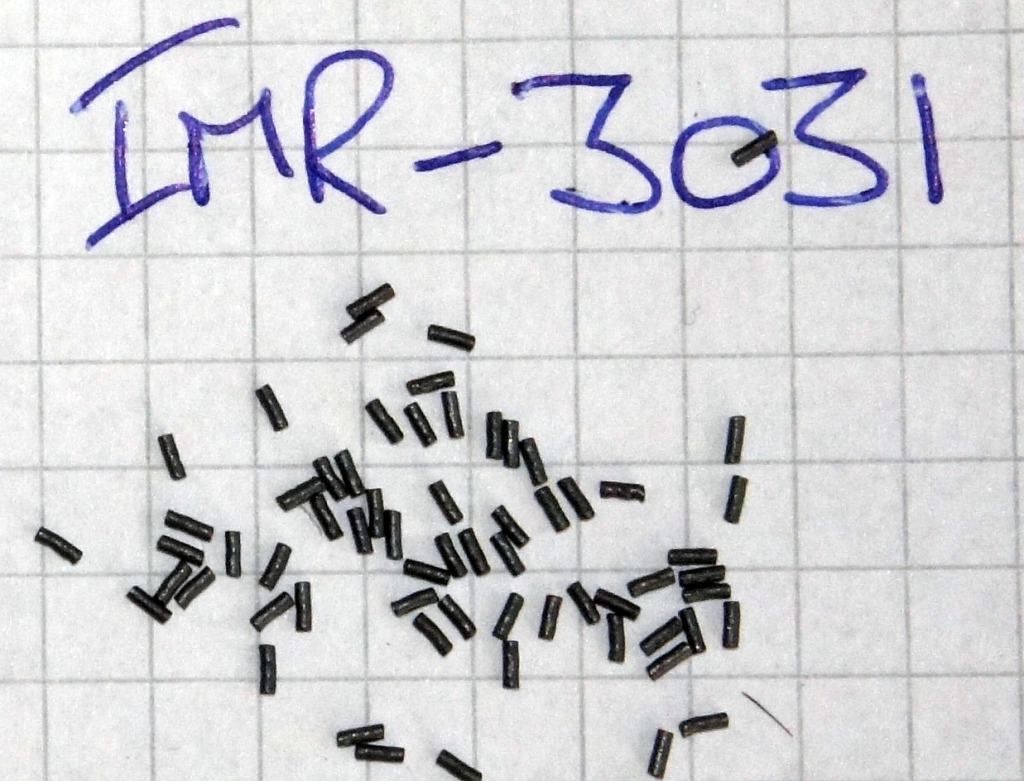

Whilst density is mainly determined by granule size, shape and, in the case of tubular grades, the central hole diameter, powders containing nitroglycerin are heavier than single-based types for any set of dimensions – 960 g/ltr for Viht N500s v ~910 g/ltr for N100s. Old-fashioned, skinny, long-grain single-based extruded powders such as the DuPont Industry’s versions of IMR grades of a couple of generations back, often referred to as ‘log powders’, take up a great deal of room and, that’s one reason why propellant manufacturers and suppliers led by Hodgdon have moved to ‘short-cut’ versions, now encompassing entire powder ranges.

Case capacity varies between makes, even manufacturing lots. I touched on this in my recent look at Viht N500 powders in the 260 Rem. There is around 1.5gn difference between the charge weights of a moderately coarse-grained powder at 100% fill-ratio in Peterson and Remington 260 brass. Obviously too, the cartridge OAL you seat the bullet to affects case fill-ratio as a shallow seated bullet takes up less space than the same design seated deeply. COAL should however always be determined by other metrics, primarily the seated bullet ogive’s position vis a vis the start of the rifling lands and/or whether the cartridge has to fit a magazine. If I’d been loading the SPR’s 260 Rem cartridges for magazine feed and/or a standard chamber, the 142gn Sierra MK bullets would have required seating some 130 thou’ deeper in the case and the N560 fill-ratio would have increased from 104 to 108%, usable but approaching my comfort zone ceiling.

Vibratory Aids?

We can’t change case capacity or powder density other than through purchasing different products, but we can and do change actual fill-ratios by how we pour the powder and whether we use ‘charge settling’ techniques or equipment. The picture shows carefully weighed 27gn Viht N150 charges that had been poured into identical (Lapua 223 Rem) cases using different funnels and methods. The left-hand case’s charge was poured normally through a standard powder funnel without a drop tube; the right-hand example with its lower level was poured slowly through a Forster funnel with its five-inch drop tube using a ‘swirl-pour’ technique.

A friend made me a 30-inch drop tube fitted to a plastic Lee funnel body for a particular application. It is very unhandy in use needing the cases placed in a loading block on the floor (or my standing on a chair if the cases stay on the bench) but settles charges more than the Forster product. Vibratory settling by placing anything that vibrates at high speed such as an electric toothbrush head against the case body reduces the charge volume still more. (Just remember to put a finger on the case-mouth, or granules will jump out.)

Studies carried out by the American H P White Laboratory for the US NRA back in the 1950s or early 60s showed there are downsides to some charge settling techniques, especially vibration. Using the .30-06 Springfield cartridge, a heavy bullet and an IMR ‘log powder’, increasing amounts of charge compression were employed and the results fired through a pressure barrel. Up to and including heavy compression produced no increase in pressure or change to average MVs. What it did produce was more consistent MVs, ie ES/SD values were reduced. However, charge settling that removed the need for any physical compression by employing an ultra long drop tube, even more so vibratory methods, produced a small but consistent MV/pressure reduction and a corresponding significant increase in ES/SD values.

Uh? This is counter-intuitive even if it again contradicts the ‘Compressed loads put pressures through the roof’ belief. It results from how the charge ignites in the case. The primer doesn’t work like a match flame held against the end of a cigarette which then burns evenly along its length – it blasts superheated gas and incandescent aluminium or other solid particles far into the charge, it’s believed right up to the shoulders in many cartridges. To do this, there have to be gaps (‘interstices’ to use the technical term) between the granules. If the gaps are too large as in uncompressed ‘log-powder’ loads, primer energy is wasted in heating up these air pockets. Conversely, if the gaps are too small or non-existent, primer particle and gas penetration are reduced so ignition efficiency drops and becomes less consistent.

The 338 Federal

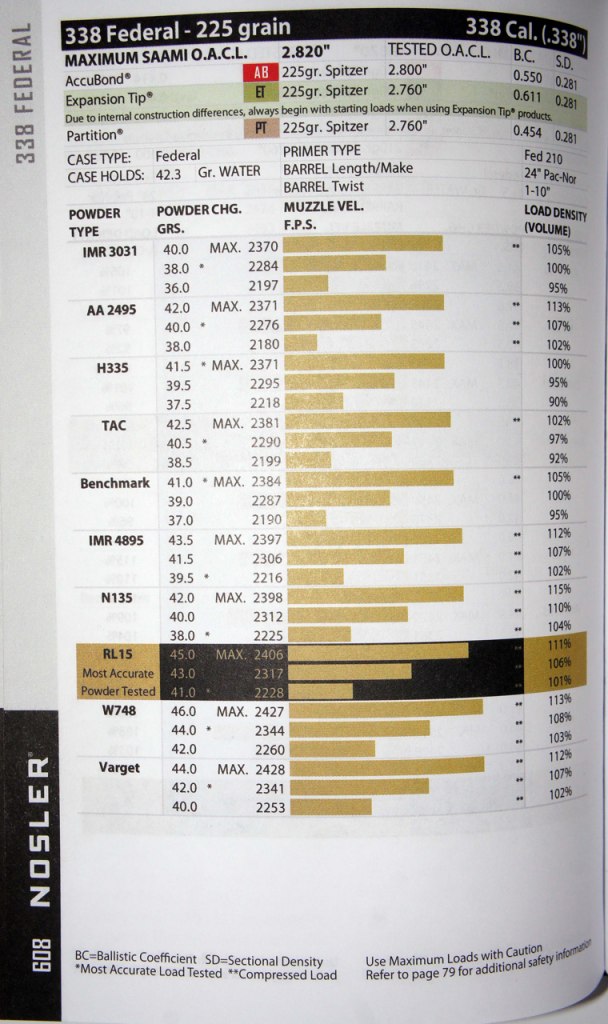

It’s probably obvious why I chose this cartridge. See Nosler’s page for the 338 Fed and its 225gn bullets in the new Number 9 manual

Of the ten powders listed nine are shown with at least one compressed charge (** indicator) and six have all charges including the starting level shown as compressed up to 115% for Viht N135’s maximum.

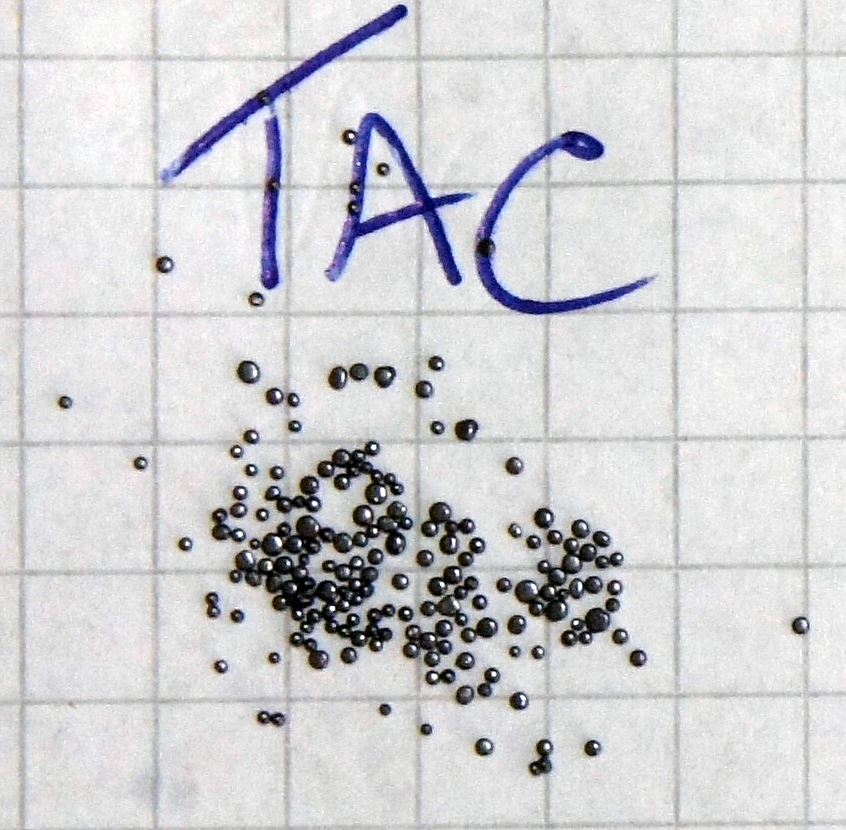

Interestingly, a ball powder – Winchester 748 – is one of the most heavily affected propellants at 113% fill-ratio for the top load. I say ‘interestingly’, because some people put this type among the exceptions to the rule that sensible compression is OK. So, you can see why I chose this cartridge – it’s a serial offender. It also has the advantage that test rounds will usually be loaded to 2.800 – 2.820” COAL and there is only one factory case available (unsurprisingly from Federal). Most testers use the F210 primer and a 24-inch test barrel is the norm, so we can compare different reloading manual data without other factors such as different case makes and capacities affecting charge weights and fill levels.

Exceptions

Every handloading ‘rule’ has an exception (or ten). Excessive compression can degrade performance and in a few cases involving stupidity may be dangerous. (Murphy’s Fourteenth Law: If anything can’t go wrong on its own, someone will make it go wrong). I mentioned in the 260 Rem feature that the 48gn maximum charge of Viht N565 saw a tiny degree (0.002”) of push-back on the bullet. This leads to another factor not so far mentioned, case-neck tension. I run my match cartridges with light tension so the neck grip on the bullet isn’t strong. A standard sizer die from Lee, RCBS, Hornady etc would have imparted a great deal more tension. So most sporting cartridges loaded with off the shelf brass and tools (as in 338 Fed) will have to see severe compression before COALs start to misbehave. This is the missing bit of what Lyman has to say on the subject – ie how to recognise excessive compression. If COALs increase over what you’ve set the seating die for, then the amount of compression is excessive. If an immediate post bullet seating check turns out OK, Lyman advises a recheck after 24 hours as push-back often takes place gradually. Obviously, these checks only need apply where you know or suspect the charge is being compressed.

If bullets are pushed out, there are penalties. First, the amounts may not be uniform giving a range of COALs. As one objective of handloading is to craft the ammunition to your rifle and its chamber, and consistency therein is king, then incorrect and inconsistent dimensions are both very bad things. Cartridges whose OALs have grown may no longer fit the rifle magazine, or once in it, stick and produce mis-feeds. Lastly and worst, the COAL may now be such that the bullet is pushed into the rifling lands when you chamber the round. If you’re lucky, it’ll be such a large increase that you have difficulty closing the bolt. In worst-scenario cases, an already maximum pressure round risks becoming a seriously over-pressure one due to the bullet being jam-seated into the lands. (Also, if you try to unload such a cartridge having twigged something is wrong, the case and bullet often separate leaving the bullet stuck in the barrel and the action and locking recesses full of powder kernels.)

Squeezed Balls

When I started handloading a long time ago, many reloading manuals advised against compressed loads with ball powders, but didn’t make clear why. Over the years, manuals with one exception have dropped the admonition and you’ll find many examples of compressed ball powder charges if you look for them, same too in the loading data-sets from their manufacturers. Where I have seen caveats, it comes back to those air-gaps or interstices. The argument goes that the little round granules naturally sit close to one another making it harder for the primer ejecta to penetrate the column. (Perhaps that’s another reason why ball powder loads often do better with hot magnum primers?) Compress the powder column so they’re forced into hard contact and the primer has a near impossible task.

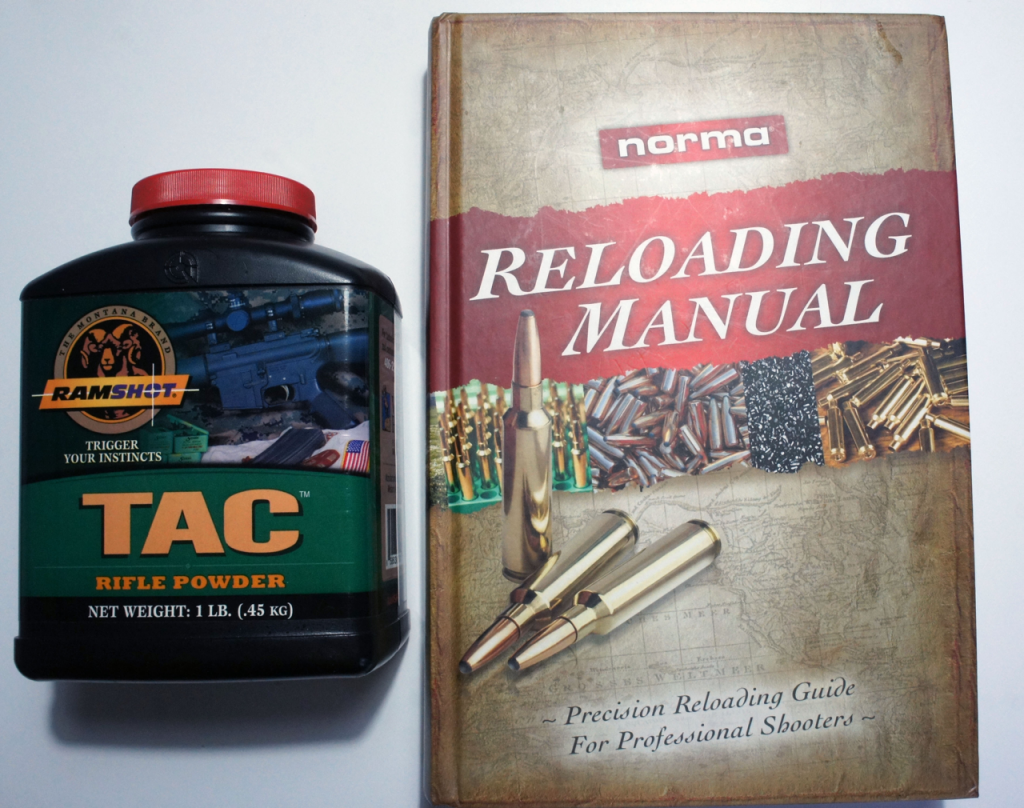

Norma goes further in its current Reloading Manual (2nd edition pub 2013). In a section called Differences Between Ball Powder and Extruded Powder it says:

“One of the disadvantages of a ball powder is that it must not be compressed. There must always be a small air gap between the powder and the projectile into which the initially generated gases can expand. If the charge is compressed, there will be pressure waves within it, of such a magnitude as to damage the weapon. Extruded powder can be compressed without any problems since the initial gases will always find space within the granules and between them. With ball powders the charge will be dense because it is compressed, and when ignited the charge will be driven, more or less, like a piston.”

Return to Nosler’s 338 Fed / 225gn bullets table (Fig. 2) and we see Winchester 748 ball powder with a charge weight that produces 113% fill-ratio – seriously compressed! I can’t comment on this disagreement between companies, chemists and engineers who know far more on this subject than I ever will and can only note that Norma is the lone dissenting voice on this aspect of loading the type. Nevertheless, I don’t use moderately, let alone heavily compressed ball powder charges. Intuition wins out over evidence here!

Reprise

When I started out on this piece, I envisaged writing a short report on a straightforward subject. I discovered that compression is anything but simple and is heavily nuanced. I’ve by no means covered the subject fully – there is one interesting source (Any Shot You Want, the A-Square reloading and rifle manual) that advocates powder compression in some scenarios but, these situations aren’t relevant to target shooting handloads.

What is relevant is that the number of cartridges and bullet/powder combinations that regularly induce compressed loads has risen in recent years, a trend that shows no signs of abating anytime soon. So it surprises me in retrospect how little attention handloading sources, especially reloading manuals, give it with one or two exceptions. This goes right down to whether an indication of compressed loads is provided. Particularly surprising is the omission of mention of even minimal length powder funnel drop tubes or any other settling techniques.

Going back to first principles, there will be many who’ll question the need for using a compressed load at all. With a wider choice of powder types than we’ve ever had even after ‘REACH’ losses, they’d say we should simply use another propellant if the one on the bench will end up heavily compressed. Let’s return to the 338 Fed – for the last time, I promise! (Figure 2.) It’s difficult to avoid compression completely using Reach-compliant powders. Ramshot TAC is the best option, but its availability around the UK is ‘spotty’. If you’re happy with negligible to mild compression, you could treat Viht N135’s and Alliant Re15’s starting loads as maxima but, lose nearly 200 fps MV as a result. With access to QuickLOAD or similar and a willingness to move outside the comfort blanket of ballistic lab and pressure-tested data, there are a few other powders that might perform well with nil or low compression.

The 338 Fed points up one reason why compressed loads are on the rise despite the countervailing improvements in powder bulk densities. That is ever shorter cases are being employed, a necked-up 308 Win here, in order to fit particular size actions. The 458 Win Mag was designed 65 years ago to squeeze large African dangerous game cartridge performance into the then standard (30-06 length) American rifle action; the 338 Federal arrived exactly 50 years later in 2006 designed for the now dominant US ‘short’ action and magazine to produce a modern replacement for long-obsolescent heavy game woods cartridges like the 348 Winchester. However, if you can’t live with compression, but still want a woods hunting 338, the next entry in the Nosler manual is the 338-06 A-Square, ie a necked-up 30-06 case. There is barely a compressed load in its tables and, you get more performance and flexibility too, BUT ….. It needs a long action so an extra half-inch rifle length and 6-8oz weight; longer bolt-throw; nobody offers factory rifles or ammo. Anyway, long actions are so yesterday, Sweetie! (In a custom build, I’d choose the 338-06 any day, but I’ve long been a metaphorical ‘dinosaur’!)

The 21st century appears to be accelerating the trend with new cartridges like 6.5mm Grendel and its 6mm-ARC spin-off; the 224 Valkyrie and 22 Nosler; 6.8mm Rem SPC and others squashed down to 2.26-inch COAL to fit AR-based platforms and magazines; the Creedmoors have smaller cases than 308 Win, never mind earlier generation designs like the 6.5X55mm and, the 308 in turn was designed (as 7.62 Nato) to give 30-06 M2 performance in a half-inch shorter case and action. To work, these truncated designs need dense, high energy powders and, often a lot of them packed in, to create the higher pressures that are needed to deliver acceptable performance. ‘Push’ performance further and very high pressures and charge compression with their attendant risks loom large.

But it’s not just case, cartridge, or action lengths. Performance standards and expectations, propellants and bullets have changed greatly and continue to do so. A plethora of high-energy, short-cut or ball technology slow burners have been introduced and although intended primarily for over-bore capacity magnums many have been adapted to short-action numbers such as 6mm Creedmoor. Why? … an extra 50 fps MV and a move up into the next accuracy node. However, use a slower burning powder and charge weights and volumes have to increase …….

Recent bullet introductions are heavier and higher BC. Both trends make for longer projectiles, an extra tenth inch, getting on for two with the latest super-weight/streamlined 0.264” cal models. This is no issue for single-shot prone shooters like myself, who just need to ensure the chamber is suitably throated but, a different matter for the tactical/PRS shooter who has to load ammunition to fit short-action magazines from AI, MDT, Tikka or whoever. A longer bullet within a fixed COAL means more shank and tail below the case-neck leaving less room for powder and higher fill-ratios. The use of slow burning propellants and the search for higher usable pressures and velocities require heavier charges which in turn risks greater compression. The remarkable thing is that – so far – shooters are managing to reconcile these discordant factors and obtain very high MVs and excellent precision.

Going back to those who believe compression is inherently unsafe, I’ll agree many over-pressure incidents that lead to these views do involve heavily compressed charges but, believe that’s a side-effect of the use of too much powder, often an unsuitable grade for the application. Massive degrees of compression allied to crudely applied bullet-crimps are frequently signs of other basic errors committed by those few dangerously incompetent handloaders who are living proof of the veracity of Murphy’s 14th Law and not in themselves the cause of excessive pressures (unless COALs grow enough to put bullets into the rifling). However, if you find a new load comes half way up the case-neck, that’s certainly a sign to check out. Go back and verify the data. If they check out but you’re still unhappy, don’t use it – there are nearly always alternatives these days. Oh, and if you don’t already own one, buy a powder funnel with a drop tube, or a multi-purpose funnel kit which includes a drop tube made by MTM or somebody. You’ll surely need it sooner or later.